Brick picking mechanical arm

A technology of manipulator and clamping arm, which is applied in the field of brick picking mechanism, can solve the problems of scattered hanger structure and large frame, and achieve the effects of stable frame, high running speed and simplified mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

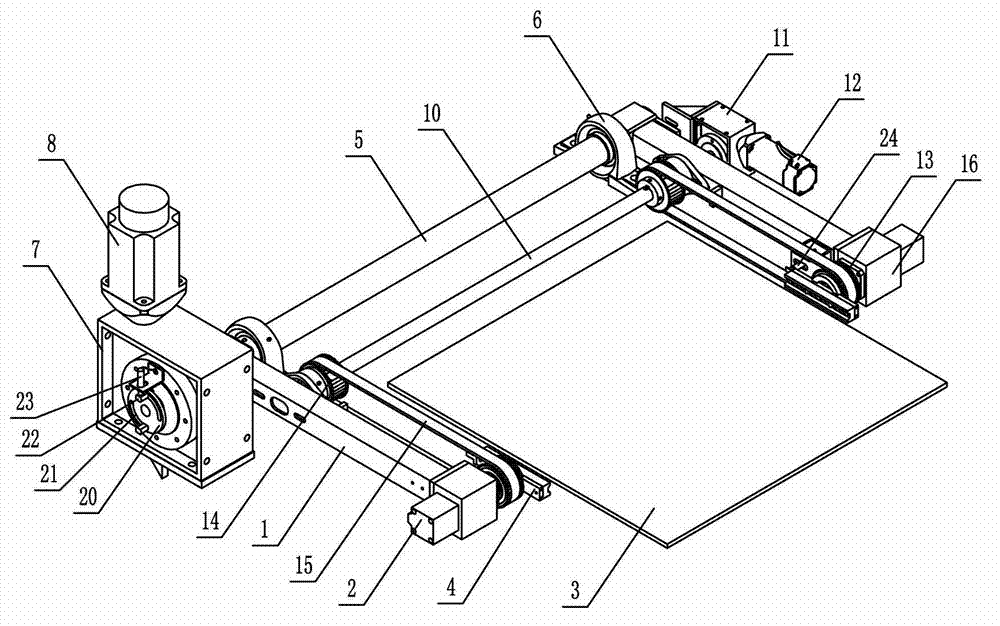

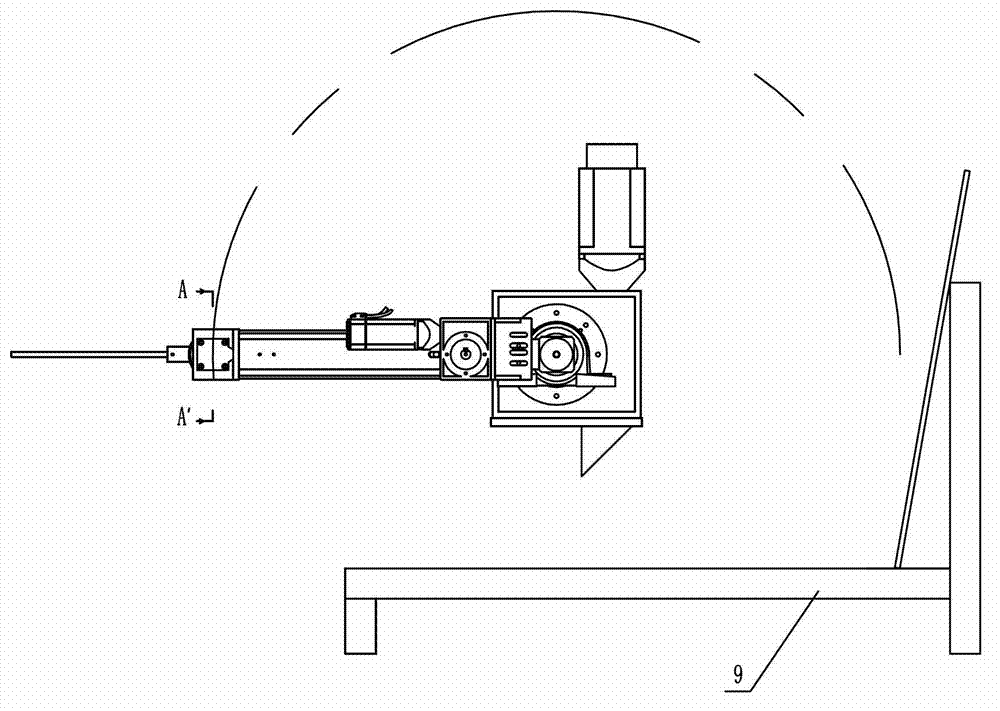

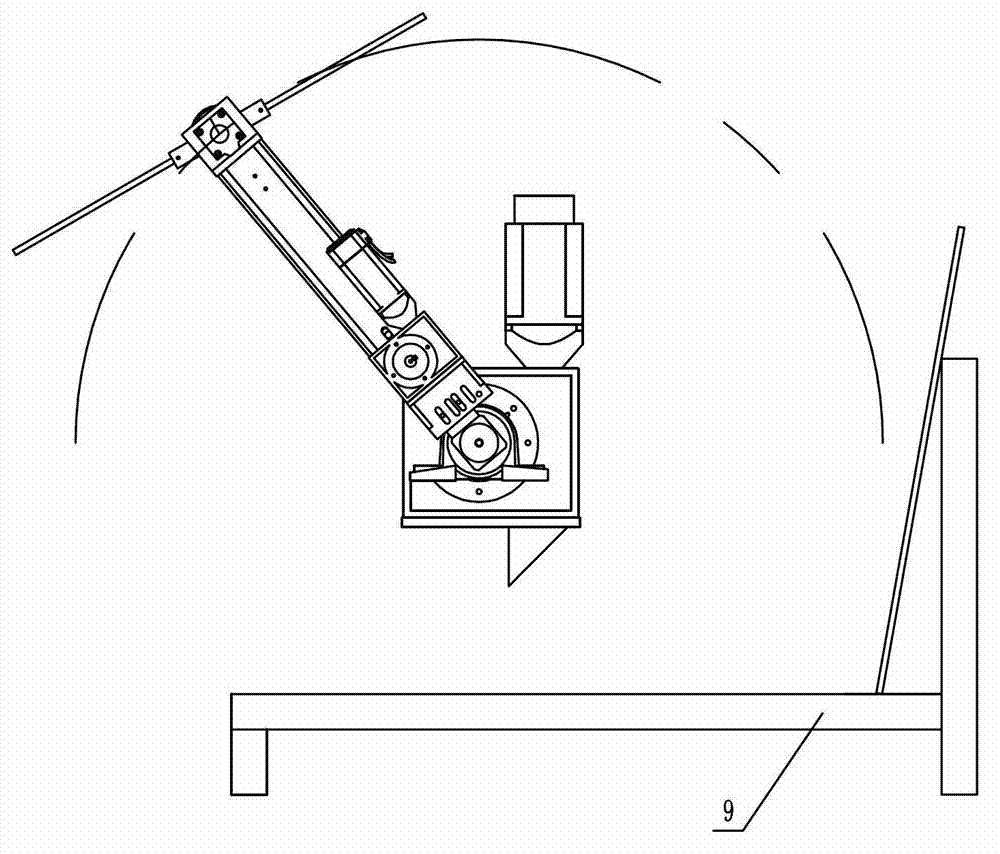

[0015] Such as Figure 1-5 As shown, a brick picking manipulator includes a clamping arm frame composed of a pair of clamping arms 1 and a chuck 4 that is installed on the end of the clamping arm 1 and driven by a cylinder 2 to clamp the two ends of the ceramic tile 3. The clamping arm The other end of 1 is fixed on the first rotating shaft 5, the first rotating shaft 5 is installed on the frame through the bearing seat 6, and the first rotating shaft 5 is driven and connected with a servo motor 8 through a reduction box 7. A rotating device for driving the chuck 4 to rotate is installed on the clamp arm 1 . When starting to pick up bricks, the chucks 4 on both sides are driven by the respective cylinders 2 to clamp the two ends of the ceramic tiles 3, then the servo motor 8 is started, the first rotating shaft 5 is rotated, and the clamp arm frame is placed toward the side where the bracket 9 is placed. One side swings until it swings to the top of the bracket 9. During the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com