Pressing and punching mold for hub reduction gear outer gear ring

A technology of wheel-side reducer and external ring gear, which is applied in the direction of quenching device, manufacturing tool, heat treatment equipment, etc. Insufficient heavy load bearing and other problems of the ring, to achieve the effect of good internal toughness, improved fatigue resistance, and strong impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

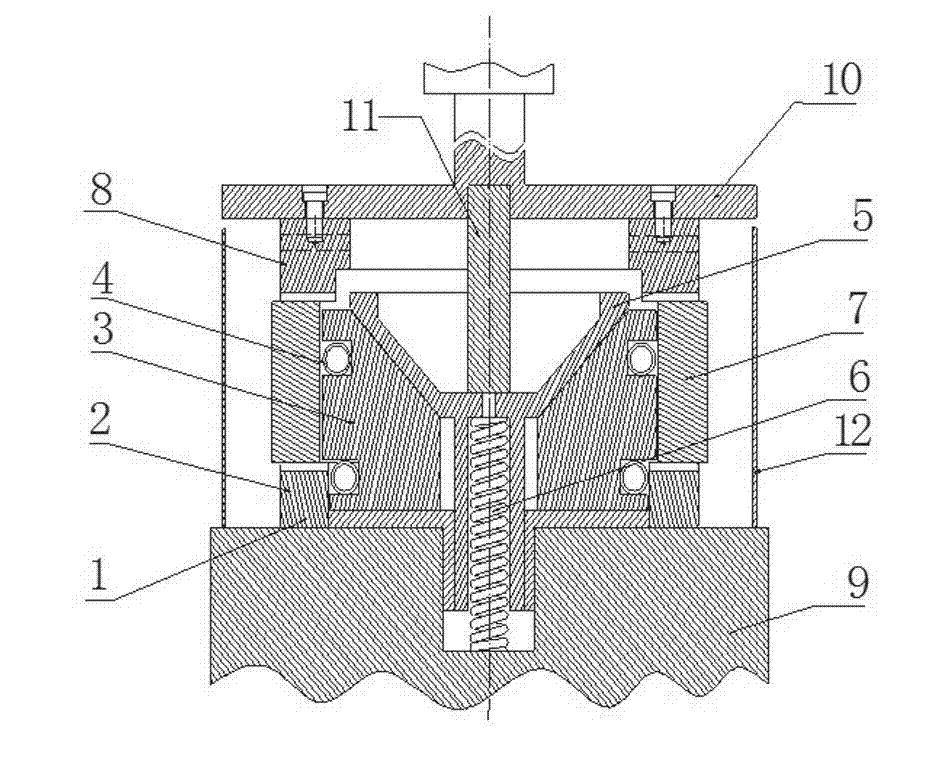

[0015] See figure 1 As shown, the present invention is a press-quenching die for the outer ring gear of the wheel-side reducer, which is arranged on the working support table 9 and consists of an upper die and a lower die. The lower die is composed of a fixed bracket 1, a quenching Bracket 2, expander 3, annular spring coil 4, pressure stabilizer 5, compression return spring 6, cooling tube 12 are composed; the fixed bracket 1 includes the upper part of the fixed bracket and the lower part of the fixed bracket; The pressure stabilizer 5 includes the upper part of the pressure stabilizer with an outer inclined cone surface and the lower part of the ring column pressure stabilizer; the working support table 9 is provided with mounting holes; the mounting holes are sequentially sleeved with compression The return spring 6, the lower part of the pressure stabilizer 5, the lower part of the fixed bracket 1, the upper part of the fixed bracket 1 supports the expander 3 with an inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com