Electromobile motor rotary shaft

A technology for motor shafts and electric vehicles, applied in the directions of shafts, shafts and bearings, mechanical equipment, etc., can solve problems such as large impact on service life and use safety, large rectangular spline fitting clearance, and spline connection failure, etc. Small, eliminate heat treatment deformation, the effect of high product assembly efficiency

Inactive Publication Date: 2012-12-12

唐海滨

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, most electric vehicle motor shafts on the market are made of 45 steel, heat-treated and tempered, and rectangular splines are used to connect the electric vehicle gearbox. Due to the large fit gap of the rectangular splines, the transmission impact is large, and the spline connection is likely to fail. Great impact on service life and use safety

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

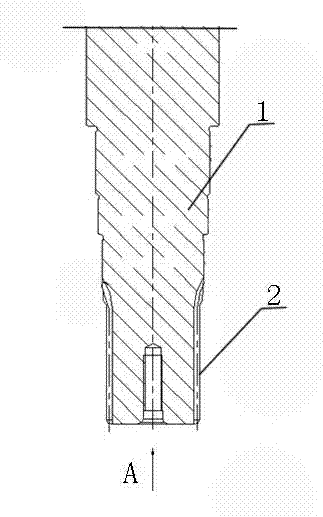

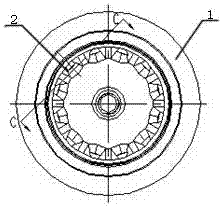

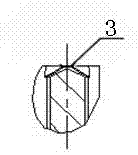

[0015] Figure 1-3 Shown is an electric vehicle motor shaft. The motor shaft 1 is provided with an involute spline 2 on the outer circular surface of the power output end, and the top of the involute spline 2 is a herringbone angle 3 structure.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to an electromobile motor rotary shaft. The outer circle surface of an output end of the motor rotary shaft is provided with an involute spline; spline teeth of the involute spline are of a herringbone angle shape; and the motor rotary shaft is prepared from 20CrMnTi super-quality alloy steel through heat treatment carburizing and quenching. The electromobile motor rotary shaft is high in bearing capability, has good drive stability, is low in noise and high in product assembling efficiency, prevents drive axial force from influencing the rotary shaft, is suitable for being used in high-speed and heavy loading conditions, and is beneficial to improving the practicability of the electromobile.

Description

technical field [0001] The invention relates to a rotating shaft, in particular to a rotating shaft of an electric vehicle motor. Background technique [0002] At present, most electric vehicle motor shafts on the market are made of 45 steel, heat-treated and tempered, and rectangular splines are used to connect the electric vehicle gearbox. Due to the large fit gap of the rectangular splines, the transmission impact is large, and the spline connection is likely to fail. The service life and use safety are greatly affected. Contents of the invention [0003] Aiming at the shortcomings of the rectangular spline connection of the electric vehicle motor shaft in the prior art, the present invention provides an electric vehicle motor shaft with small connection and matching impact, safe use and long service life. [0004] The present invention adopts the following technical solutions: a motor shaft of an electric vehicle, which is characterized in that an involute spline is p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16C3/02F16B3/00

Inventor 唐海滨卢晓辉王军

Owner 唐海滨

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com