Device and method for detecting residual reflection of neodymium glass wrapping

A technology of residual reflection and detection device, which is applied in the measurement of scattering characteristics, etc., can solve the problem of not evaluating the matching degree of refractive index of neodymium glass wrapping, and achieve the effect of fast automatic measurement, low cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

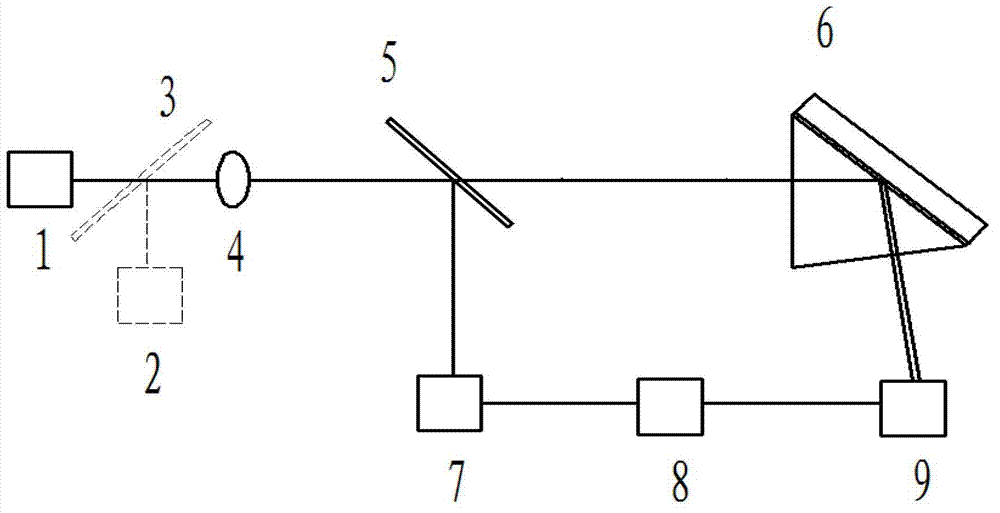

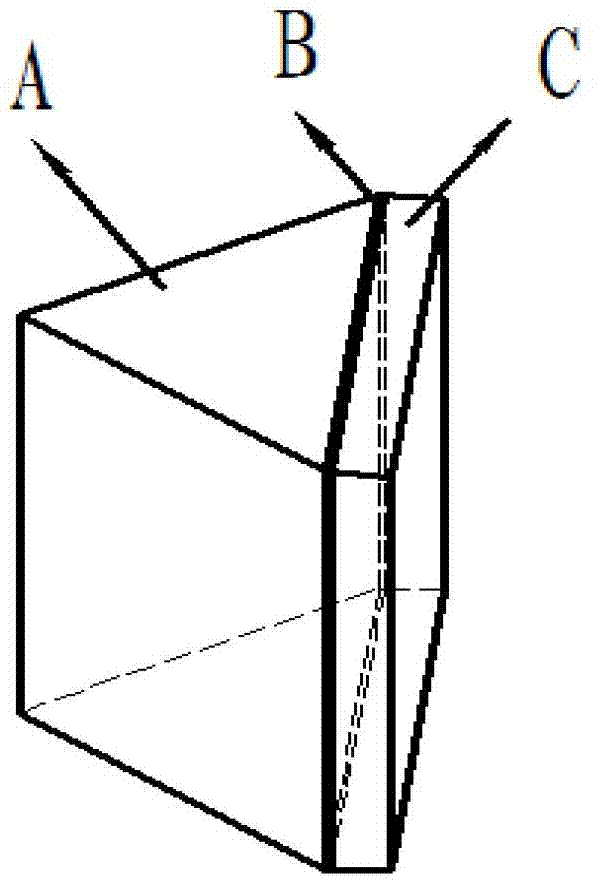

[0033] Such as figure 1 As shown, the neodymium glass edging residual reflectance detection device of the present invention includes a first laser 1, other wavelength lasers 2, a total reflection mirror 3, a beam shaping lens group 4, a beam splitter 5, a sample 6, a laser intensity detector 7, Data processing system 8 and residual reflection detector 9 . Wherein the other wavelength lasers 2 and the total reflection mirror 3 are indicated by dotted lines, showing that these two parts are not needed at ordinary times, and can be added when needed. Sample 6 as figure 2 As shown, it includes neodymium glass A, glued layer B and edged glass C, and the neodymium glass and edged glass are connected to each other through the glued layer. The sample 6 is placed on a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com