Method and device for automatically detecting and compensating zero position deviation of rotary transformer

A resolver and zero deviation technology, applied in the field of detecting and compensating resolver zero deviation, can solve the problems of difficult engineering implementation, large measurement error, high hardware requirements, and achieve the effects of low cost, convenient operation and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0034] The specific implementation steps of the example are as follows:

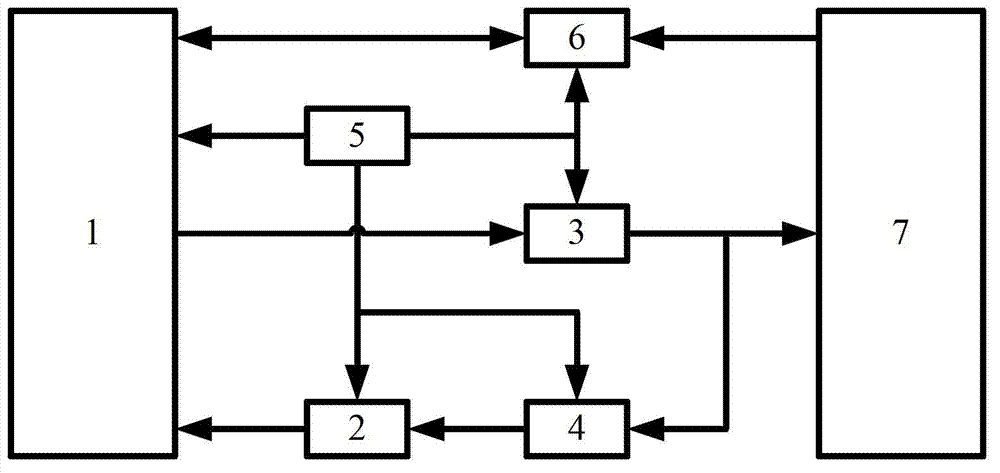

[0035] 1) The resolution circuit 6 of the resolver adopts a general-purpose 12-bit AD2S80 resolution circuit to generate a sinusoidal excitation signal of 5KHz and an effective value of 2.25V, which is sent to the resolver, and receives the output signal of the resolver for resolution. 12 channels of digital signals are sent to microcontroller 1.

[0036] 2) Microcontroller 1 sets the initial zero offset compensation value of the resolver to zero. Read the signal sent by the resolver circuit to obtain the variable RS corresponding to the rotor position of the motor, ranging from 0 to 4095. According to the value of RS, the microcontroller generates six SPWM driving signals with an amplitude modulation ratio of 0.2 through the built-in PWM module through a table look-up method, and sends them to the three-phase power driver 3 .

[0037] 3) The power drive circuit 3 connects the winding to the positive pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com