Glass substrate for magnetic recording medium, and magnetic recording medium using the glass substrate for magnetic recording medium

A technology for magnetic recording media and glass substrates, which is used in magnetic recording, data recording, recorded information storage, etc., and can solve the problems of insufficient prevention of magnetic head collision, insufficient suppression of flutter displacement, and deterioration of magnetic head floating stability. The effect of preventing head collision, improving reliability, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0065] Hereinafter, examples of the present invention will be specifically described, but the present invention is not limited to the examples. In Examples 1 to 13 below, Examples 1 to 8 are examples of the present invention, and Examples 9 to 13 are comparative examples.

example 1~13

[0067] Each process shown below was performed sequentially, and the glass substrate for magnetic recording media was manufactured.

[0068] (circular processing)

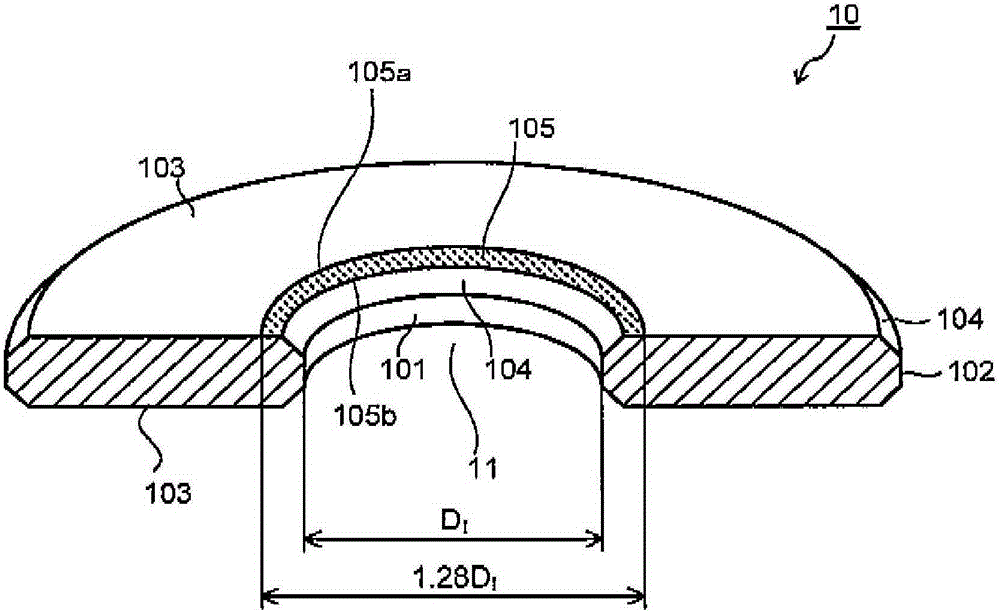

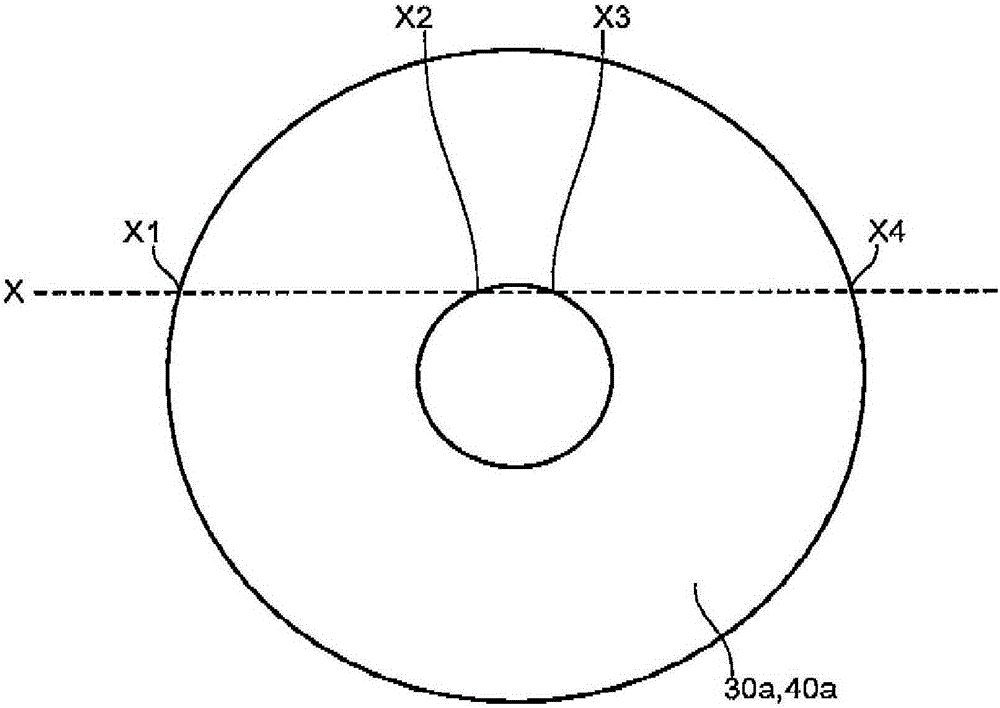

[0069]The original glass plate was processed into a disc shape with a hole in the center in such a way that a glass substrate for magnetic recording media with an outer diameter of 65 mm, an inner diameter of 20 mm, and a plate thickness of 0.635 mm was obtained. The glass original plate was formed by a float process. of SiO 2 The original glass plate as the main component.

[0070] (chamfering process)

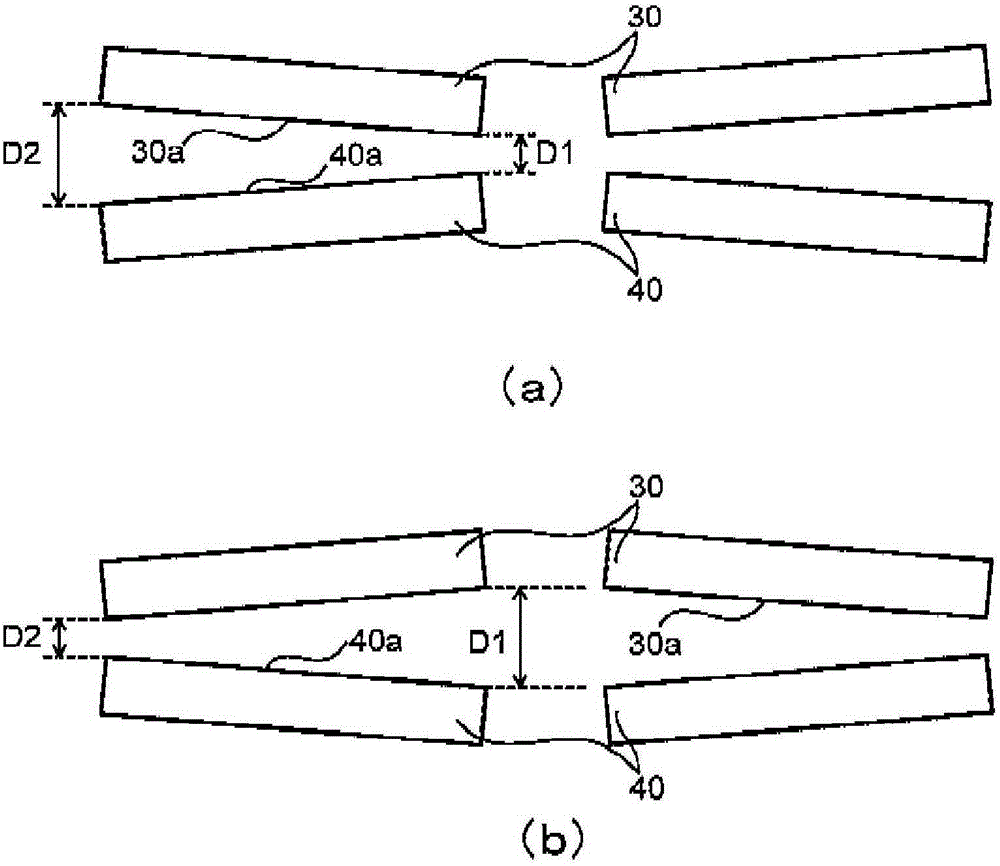

[0071] The intersection of the inner peripheral side and the upper and lower main planes, and the intersection of the outer peripheral side and the upper and lower main planes of the glass substrate processed into a disc shape with a circular hole in the center to finally obtain a chamfer width of 0.15mm, A magnetic recording medium with a chamfering angle of 45° is chamfered in the form of a glass substrate.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

| surface smoothness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com