Superconducting magnet coil with wedge-shaped section for reducing waviness and conductor winding and forming method

A technology of superconducting magnets and waviness, which is applied in the direction of superconducting magnets/coils, coil manufacturing, magnetic objects, etc., and can solve the problem of large window size requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

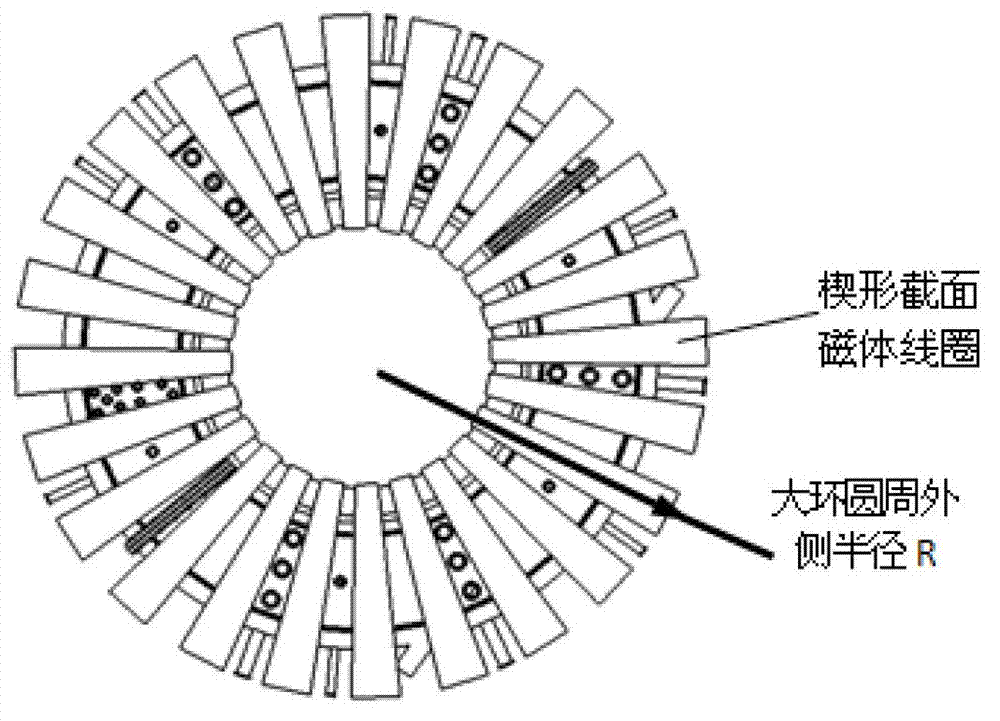

[0034] See attached picture. Symbols in the figure: 1-wire, 2-insulation spacer, 3-central support column, 4-forming block, 5-assembly hole, 6-positioning block, 7-interval between adjacent forming blocks, 8-conducting wire Lead-in and lead-out lines.

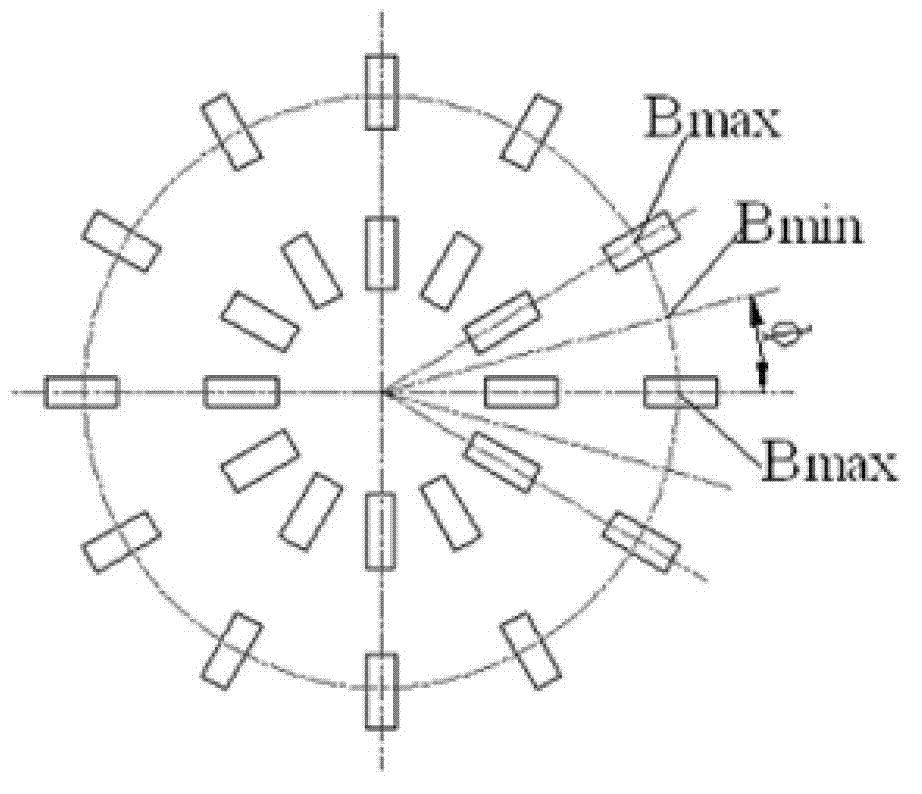

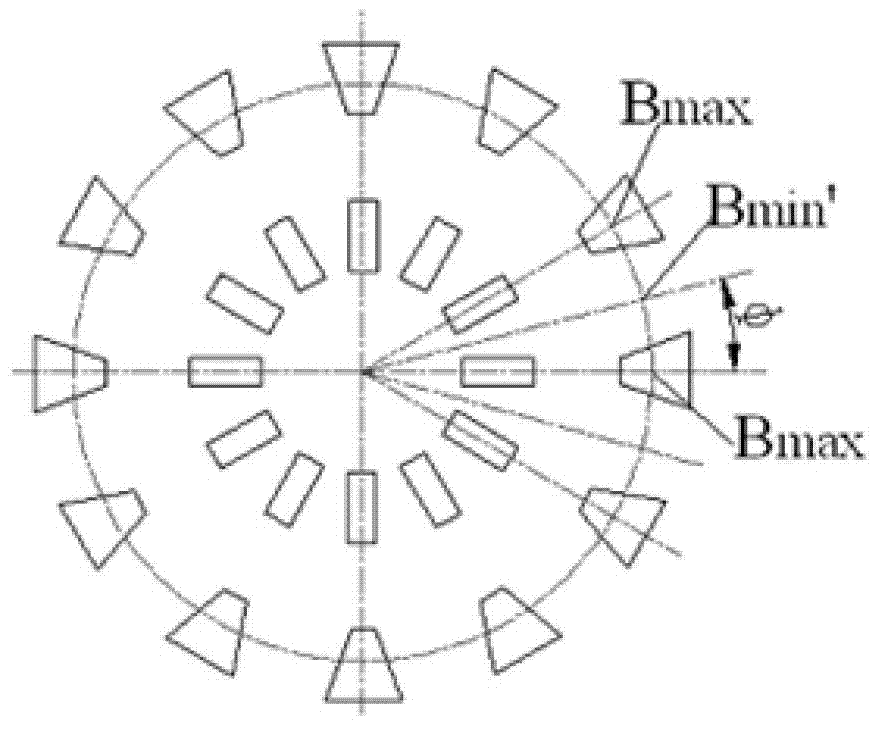

[0035] A wedge-shaped cross-section superconducting magnet coil for reducing waviness, including a D-shaped coil, the D-shaped coil is formed by winding a wire 1, and the D-shaped coil includes a straight line segment, two small arc segments, and a large circle The section of the straight section of the D-shaped coil is rectangular, the section of the small arc section and the large arc section of the D-shaped coil is wedge-shaped, and the two ends of the straight section of the D-shaped coil and the two ends of the large arc section The part between is a small arc segment.

[0036] A method for winding and forming a wedge-shaped superconducting magnet coil for reducing waviness, including a mold, the mold includes a multi-la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com