LED (light emitting diode) light source module connecting piece

A technology of LED light source and light source module, which is applied in the direction of connection, electrical components, incandescent lamp parts, etc., can solve the problems of low maintenance efficiency, high maintenance cost, damage, etc., to avoid errors or damage, good product consistency, Quality and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

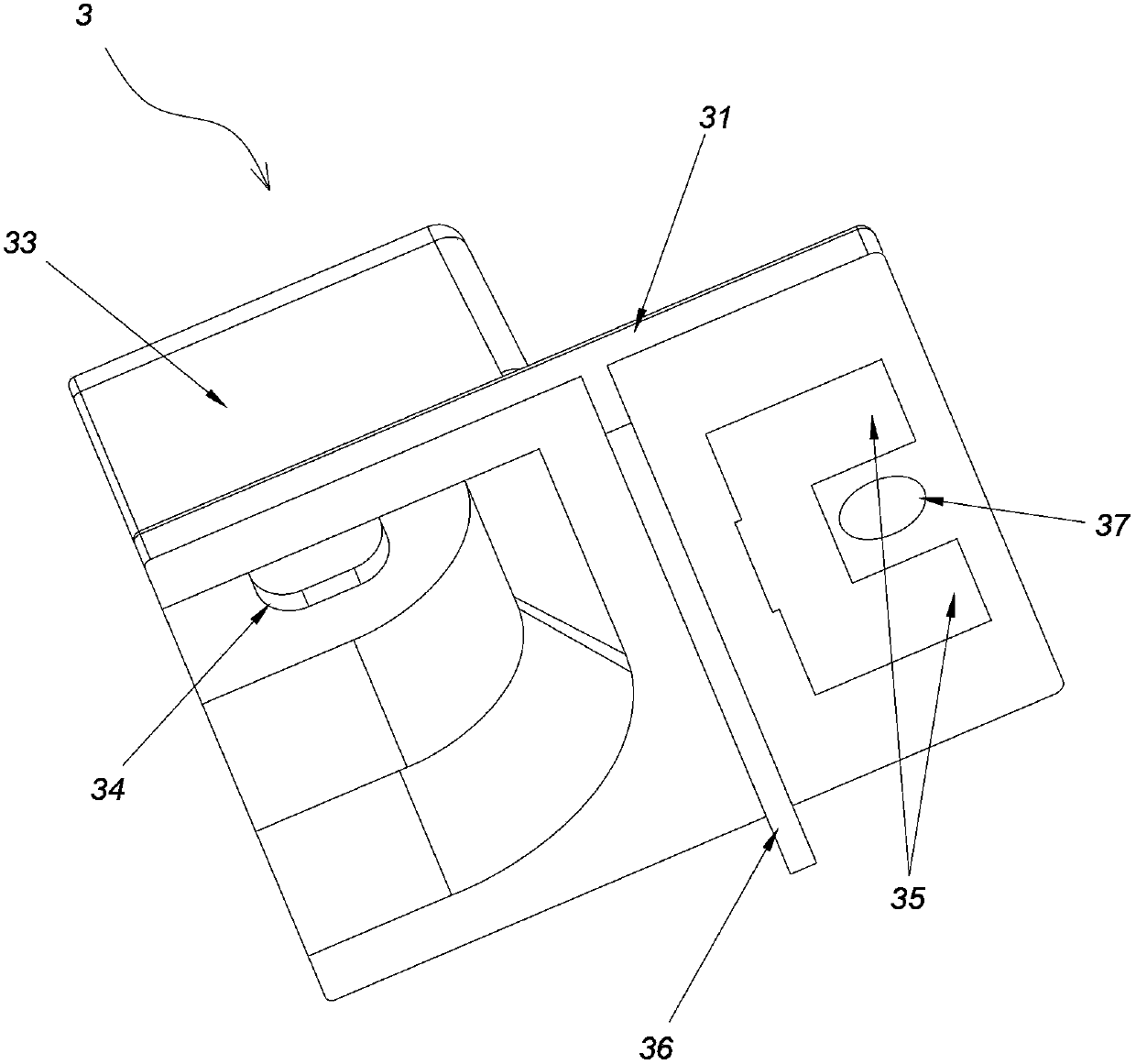

[0020] LED light source module connectors include: sockets and plugs.

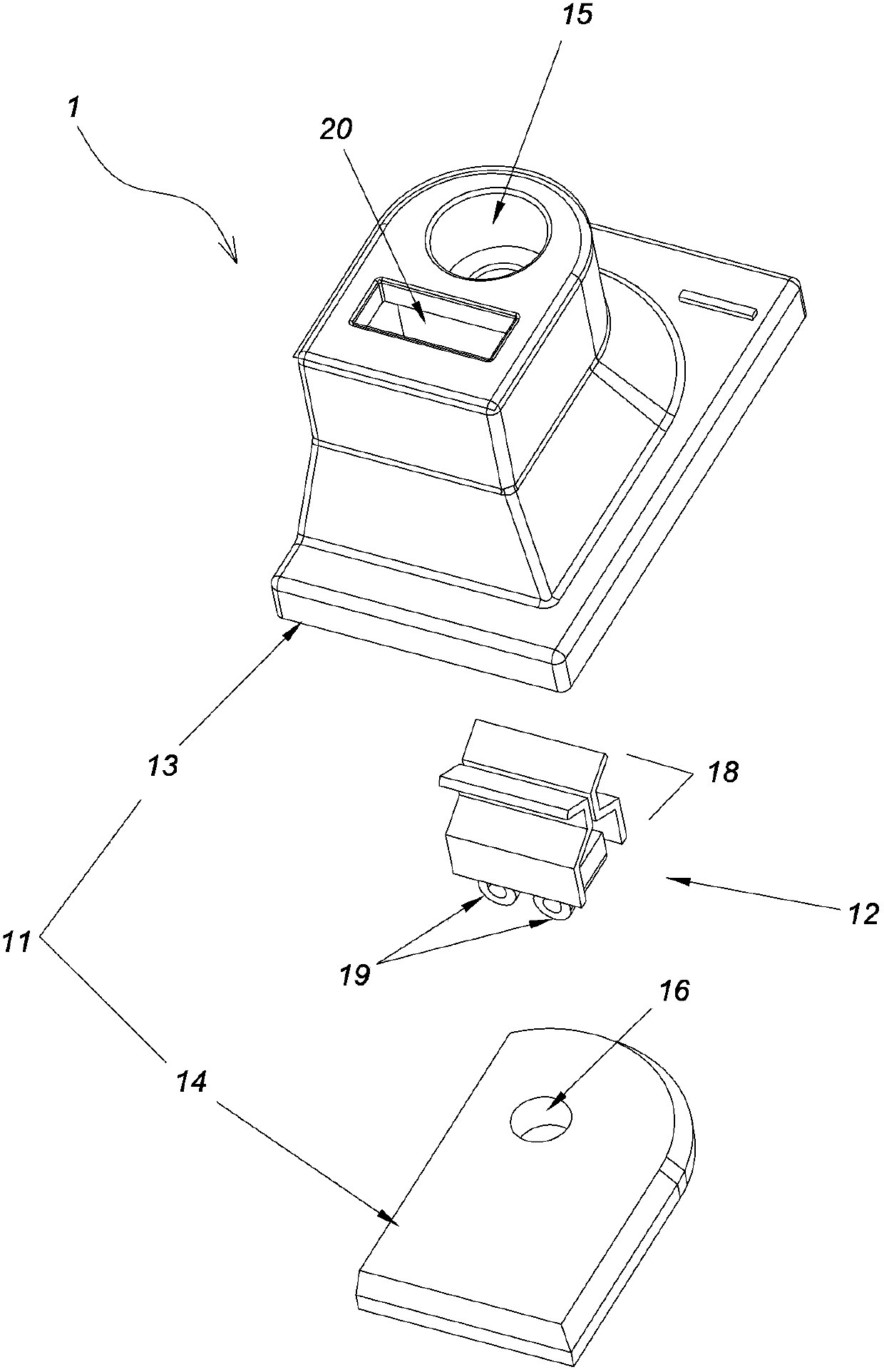

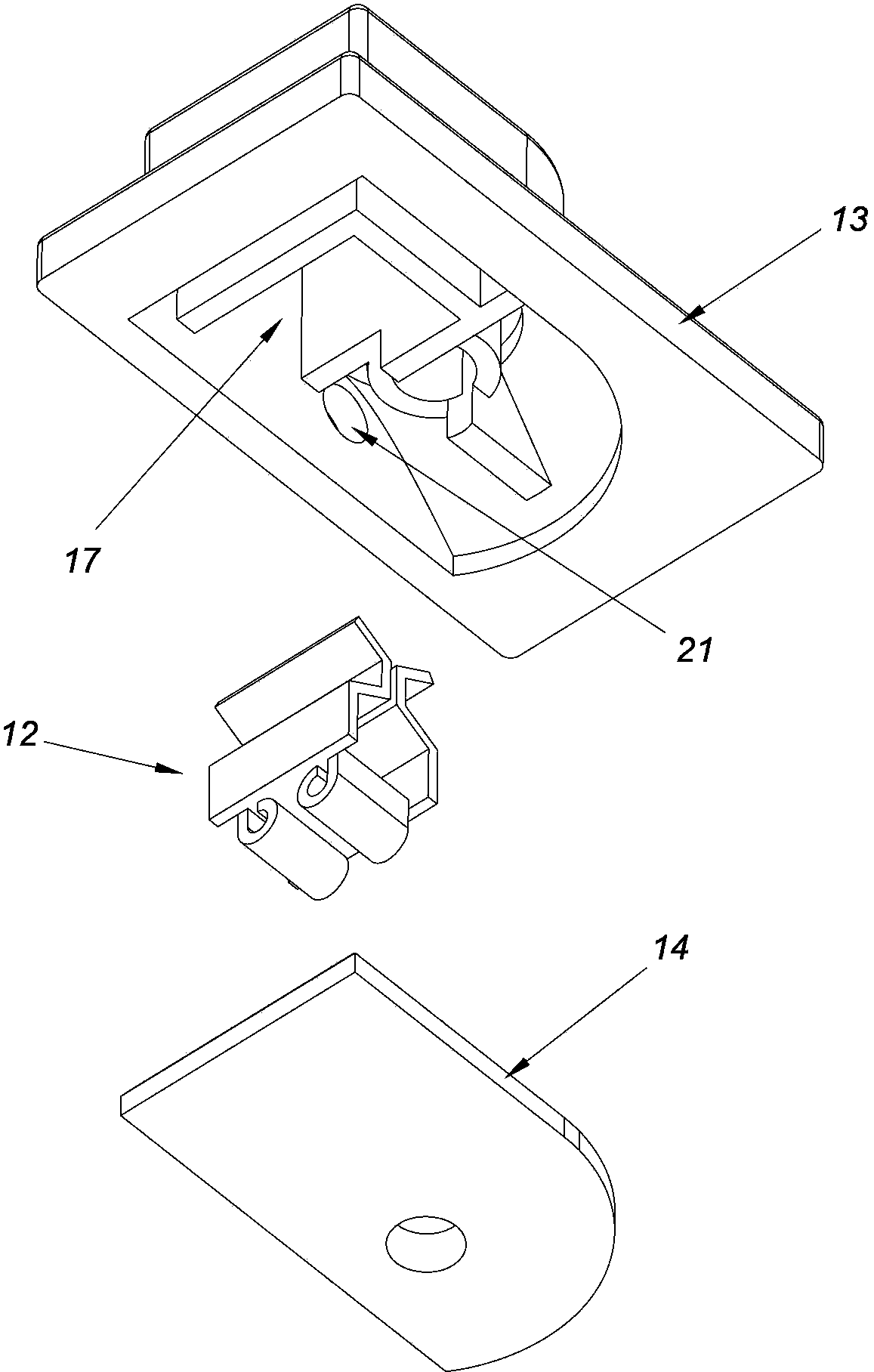

[0021] Such as figure 1 , figure 2 As shown, the socket 1 is composed of a socket housing 11 and a socket conductor 12 . In this embodiment, the socket shell 11 includes a socket upper shell 13 and a socket bottom cover 14 . The socket upper shell 13 is in the shape of a boss, and the top of the socket is provided with an upper screw hole 15 , and the socket bottom cover 14 is provided with a screw lower hole 16 . A socket conductor fixing cavity 17 is formed between the socket upper shell 13 and the socket bottom cover 14 , and the socket conductor 12 is located in the socket conductor fixing cavity 17 , thereby realizing relative fixing with the socket shell 11 . The socket conductor 12 is a metal piece with a clamping contact portion 18 and a cylindrical crimp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com