Filament and filament manufacturing method

A filament and appearance technology, applied in the field of lighting, can solve the problems that affect the aesthetics of indoor lamps and lanterns that affect consumers' perception, and achieve the effect of improving the color temperature perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

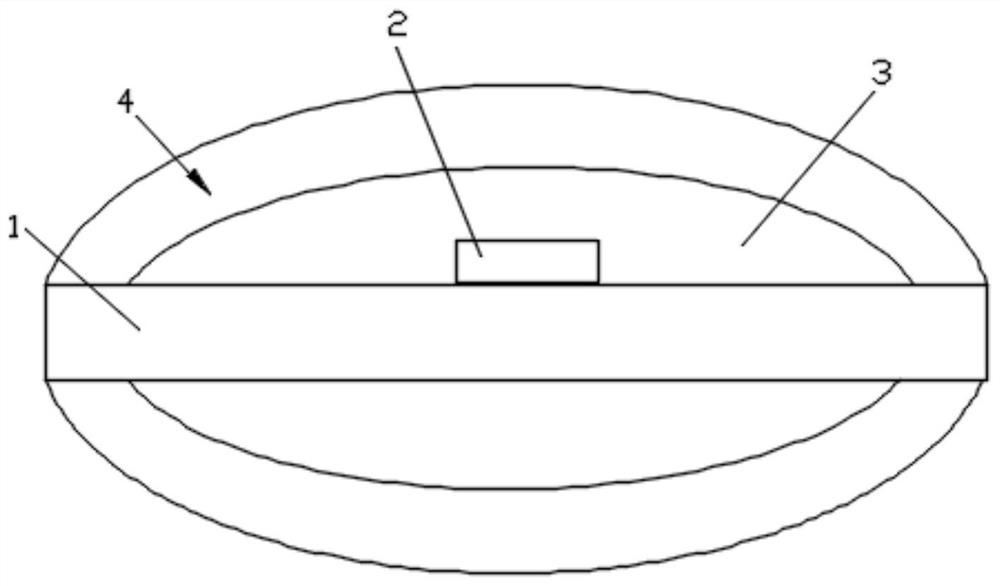

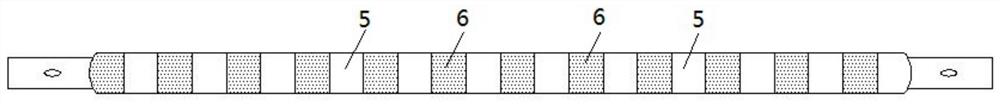

[0039] Such as figure 1 As shown, a filament includes a substrate 1, a plurality of LED chips 2, a fluorescent colloid layer 3 and a light-transmitting appearance layer 4, a plurality of LED chips 2 are electrically connected in series, in parallel or in series and parallel combinations, and a plurality of LED chips 2 are installed on the substrate 1 Above, the fluorescent colloid layer 3 is arranged on the outer surface of the LED chip 2, the light-transmitting appearance layer 4 is arranged on the outer surface of the light-transmitting colloid layer, and the light-transmitting appearance layer 4 includes any of milky white appearance layer 5 and black appearance layer 6. one or more.

[0040] Wherein, the LED chip 2 is any one of a front chip, a flip chip, a vertical chip or a CSP package chip, and the LED chip 2 is any one of a red chip, a green chip or a blue chip, so that when the LED chip 2. When emitting light, through the fluorescent colloidal layer 3, light with the...

Embodiment 2

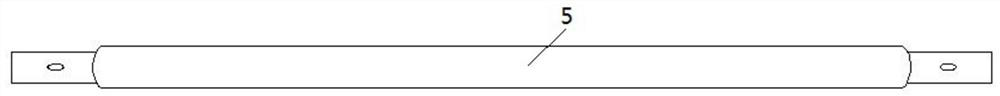

[0046] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the light-transmitting appearance layer 4 of this embodiment is a milky white appearance layer 5. At this time, the overall filament is milky white, and the same selection powder of titanium dioxide in the milky white appearance layer 5 occupies The ratio is set at 1% mass ratio, so that the filament can reach the filament brightness required for normal lighting, and ensure the aesthetic appearance of the filament without affecting the actual luminous efficiency of the filament, meeting the basic needs of users for the brightness of the filament.

Embodiment 3

[0048] Such as Figure 4As shown, the difference between this embodiment and Embodiment 1 is that the light-transmitting appearance layer 4 of this embodiment is a black appearance layer 6. At this time, the filament appears black as a whole, and the carbon powder of the black appearance layer 6 is the same selection powder When the ratio is set to 0.032% by mass, the filament can be set as a sleep lamp for the bedroom at this time, which meets the lighting brightness of the filament required by the user, and ensures the aesthetics of the filament without affecting the actual luminous efficiency of the filament, which meets the needs of the user. The basic needs of the operator for the brightness of the filament.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com