Smokeless air frying pan

An air fryer and fixed body technology, which is applied to utensils, cooking utensils, household utensils and other directions for frying things in oil, can solve the problems of large energy loss, influence effect, insufficient negative pressure suction, etc. Heat energy utilization, avoid oil fume generation, ensure the effect of cooking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

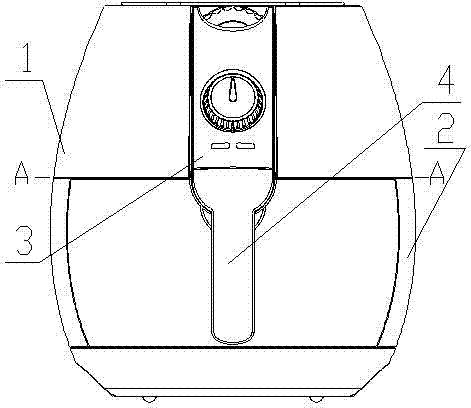

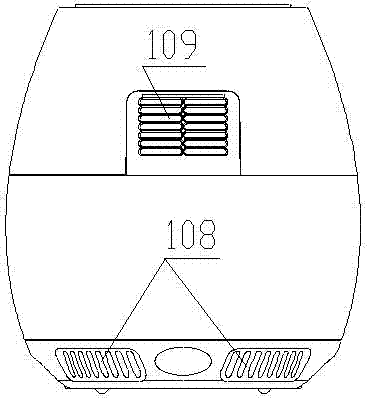

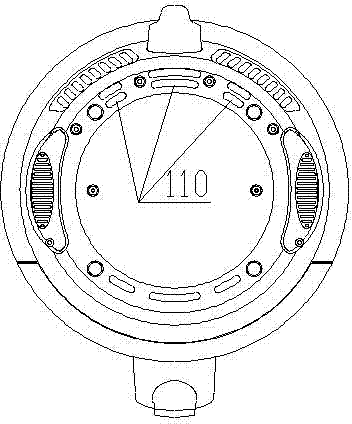

[0016] Embodiment 1: with reference to attached Figure 1-7 . A smokeless air fryer, comprising an air fryer fixed body 1 and an air fryer mobile body 2, the front part of the air fryer fixed body 1 is provided with a The jacking type power switch 301, the upper end surface of the handle 4 of the air fryer mobile body 2 and the storage net basket are locked and opened, and the jacking boss 401 is provided on one side, and the jacking boss 401 is connected with the air fryer fixed body. The jacking type power switch 301 on the side of the lower end surface of the boss part 3 in 1 is in a jacking on and off mode; the lower pressure air fan 102 in the air fryer fixed body 1 is a plane spiral electric heating tube 103, The power connector of the plane spiral electric heating tube 103 is connected with the inner wall 105 of the air fryer fixed body 1 through a connector, and the tube body of the plane spiral electric heating tube 103 is connected with the inner wall of the air fry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com