Starch-based hydrogel carrier material for controlling slow-release, and preparation method and application thereof

A carrier material, hydrogel technology, applied in pharmaceutical formulations, drug delivery and other directions, can solve the problems of difficult control of cross-linking reaction, achieve good controlled release effect, simple process and good biocompatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

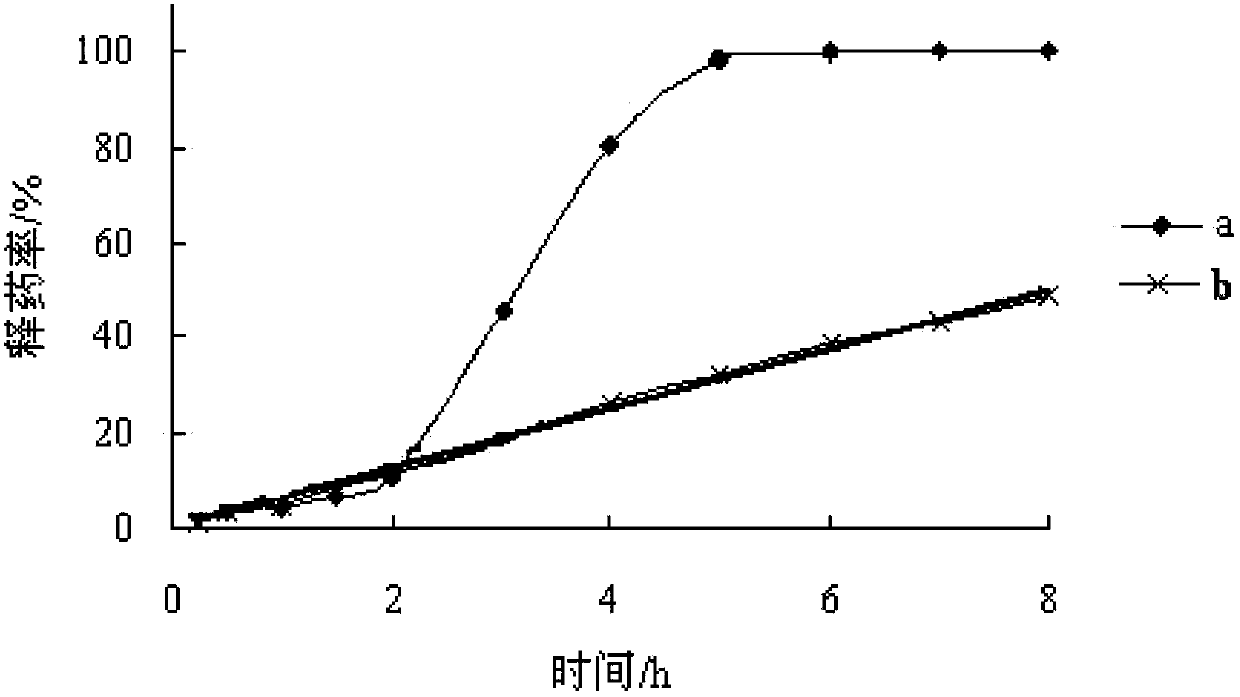

Image

Examples

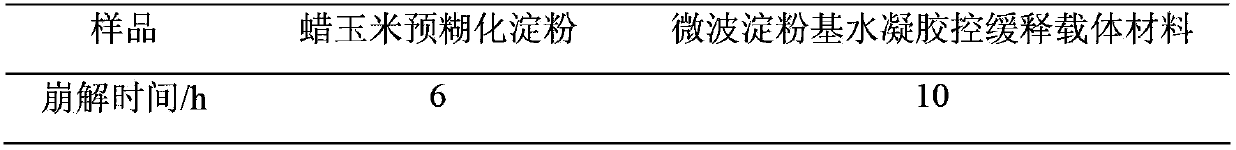

Embodiment 1

[0021] (1) Deployment of moisture content of starch samples

[0022] Weigh a certain amount of waxy cornstarch in a beaker, spray a certain amount of water into a starch sample with a water content of 25%, mix well and set aside;

[0023] (2) Microwave modification of starch and preparation of starch-based hydrogel controlled release carrier material

[0024] Weigh a certain amount of starch sample with a good moisture content and put it into the reaction tank, seal it and put it into the cavity of the microwave reaction system, control the microwave action temperature at 100°C, microwave action power 1000w, and microwave action time 120min , cooled to below 50°C, took out the starch sample and put it in an oven at 40°C to dry for 12 hours, and passed through an 80-mesh sieve to obtain the starch-based hydrogel controlled-release carrier material.

[0025] (3) Preparation of starch-based hydrogel matrix tablets

[0026] Weigh a certain amount of starch-based hydrogel control...

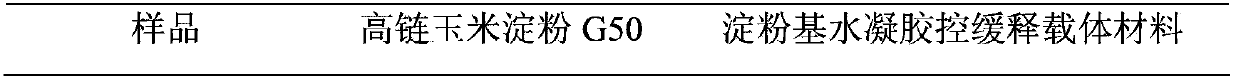

Embodiment 2

[0034] (1) Deployment of moisture content of starch samples

[0035] Weigh 500g of high-chain corn starch (G50) into a beaker, spray a certain amount of water to make a starch sample with a water content of 15%, mix well and set aside;

[0036] (2) Microwave modification of starch and preparation of starch-based hydrogel controlled release carrier material

[0037] Put the prepared high-chain corn starch (G50) sample into the reaction tank, seal it and put it into the cavity of the microwave reaction system, control the microwave temperature at 140°C, the microwave power of 800w, and the microwave time of 60min to end the reaction After cooling down to below 50°C, the starch sample was taken out and placed in an oven at 40°C to dry for 12 hours, and passed through an 80-mesh sieve to obtain the starch-based hydrogel controlled-release carrier material.

[0038] (3) Preparation of starch-based hydrogel matrix tablets

[0039] Using pancreatin as a model food functional factor...

Embodiment 3

[0048] (1) Deployment of moisture content of starch samples

[0049] Weigh 1000g of mung bean starch in a beaker, spray a certain amount of water into a starch sample with a water content of 95%, mix well and set aside;

[0050] (2) Microwave modification of starch and preparation of starch-based hydrogel controlled release carrier material

[0051] Put the mung bean starch prepared with water into the reaction tank, seal it and put it into the cavity of the microwave reaction system, control the microwave action temperature at 60°C, microwave action power 600w, microwave action time 30min, after the end of the reaction, cool to 50°C Next, the starch sample was taken out and dried in an oven at 40° C. for 12 hours, and passed through an 80-mesh sieve to obtain the starch-based hydrogel controlled-release carrier material.

[0052] (3) Preparation of starch-based hydrogel matrix tablets

[0053] After mixing the obtained starch-based hydrogel controlled and sustained-release ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com