Adjustable decontamination device of external surface of circumferential steel brush tube fitting

A decontamination device and a technology for outer surfaces, applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of difficult standardization operations and low efficiency of manual operations, and achieve simple and ingenious technical concepts and offset effects The effect of force and mechanism working smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The embodiments of the present invention will be further described below in conjunction with the accompanying drawings, but this is not a limitation of the present invention. The scope of protection of the present invention is subject to the contents recorded in the claims, and any equivalent technical means replacement made according to the specification will not depart from protection scope of the present invention.

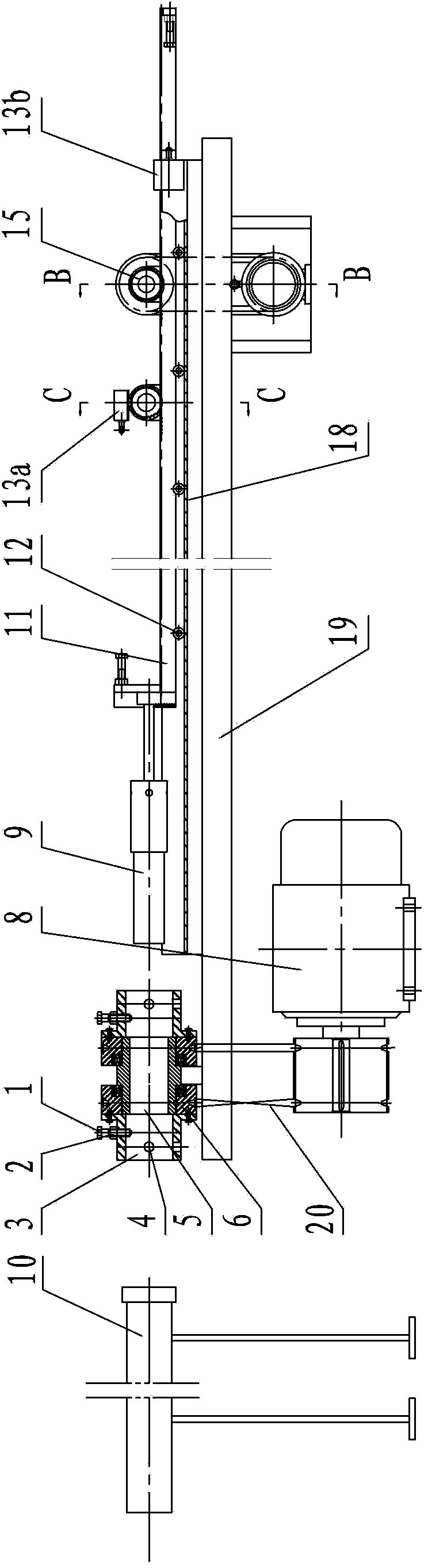

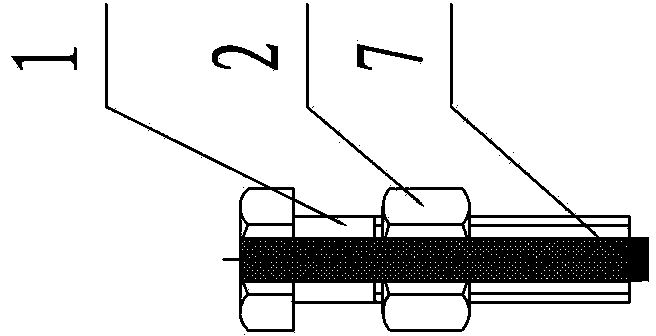

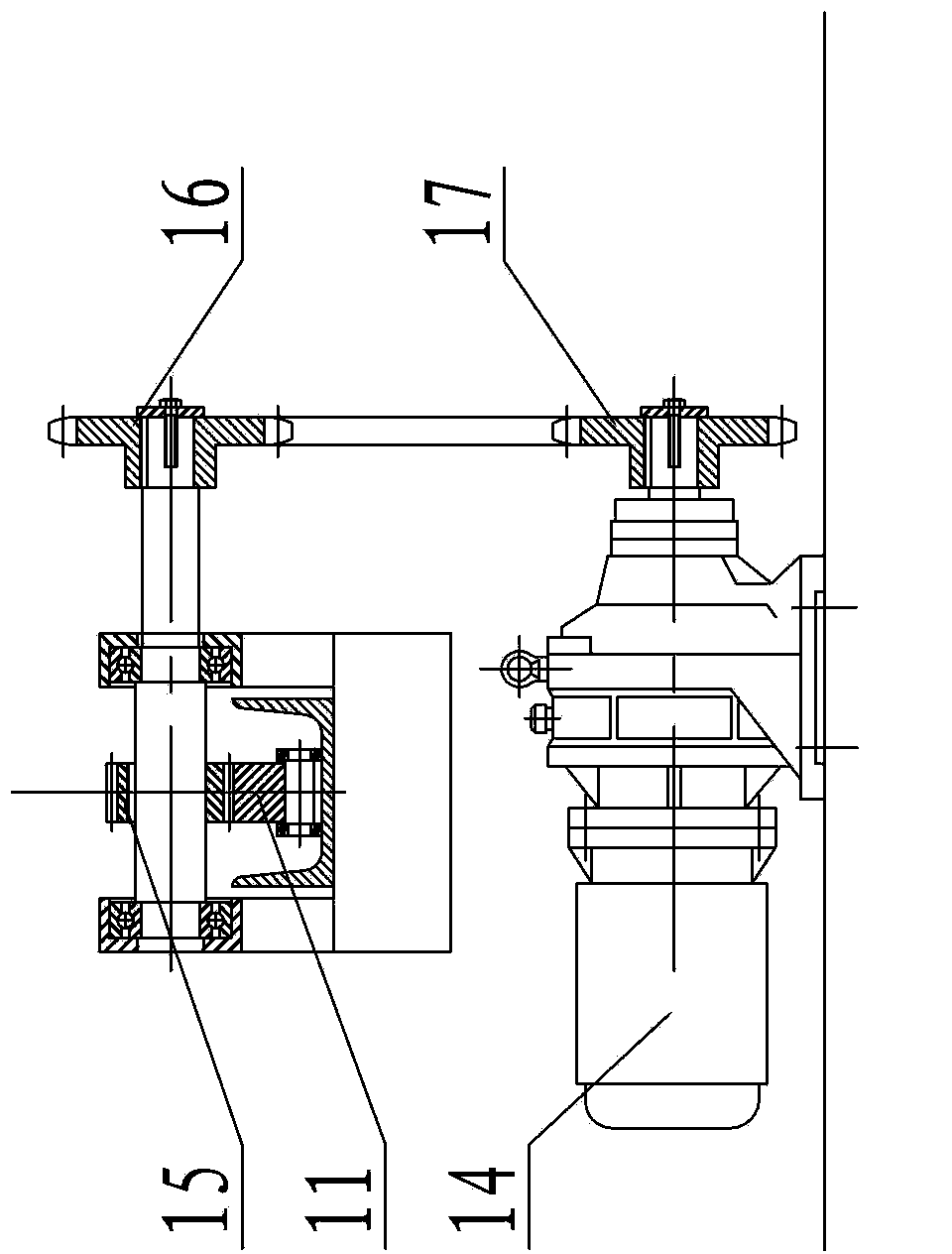

[0030] The overall structure of this embodiment is as Figure 1-4 As shown, it includes a horizontally arranged workbench 19, a drive source 8 assembled on the bottom of the workbench 19, a rotary head 3 that is arranged on the surface of the workbench 19 and is driven to rotate by the drive source 8; the inner cavity of the rotary head 3 A bristle body is arranged in the radial direction, and a workpiece feed mechanism driven by a linear drive mechanism and reciprocating linearly in the axial direction is provided at a distance from one side of the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com