Oil sludge cleaning and processing system for oil tank

A processing system and a cleaning system technology are applied in the field of oil tank sludge cleaning and processing systems, which can solve the problems of low utilization rate, difficulty in promotion, and difficult disposal of slag.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

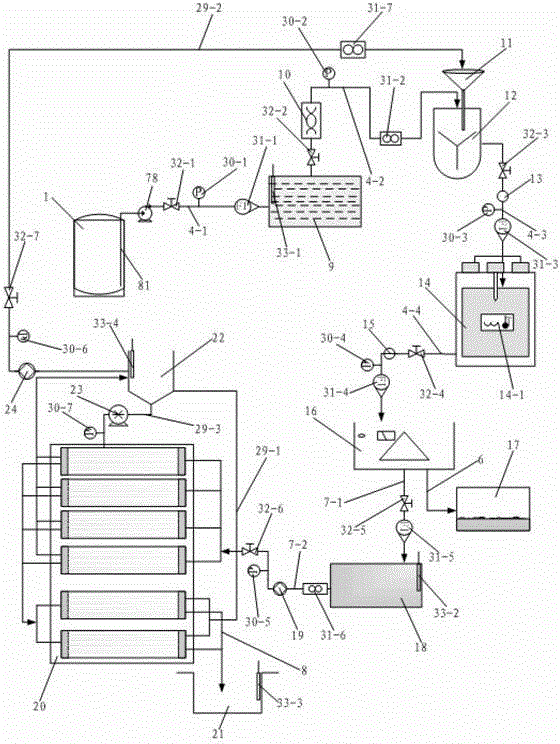

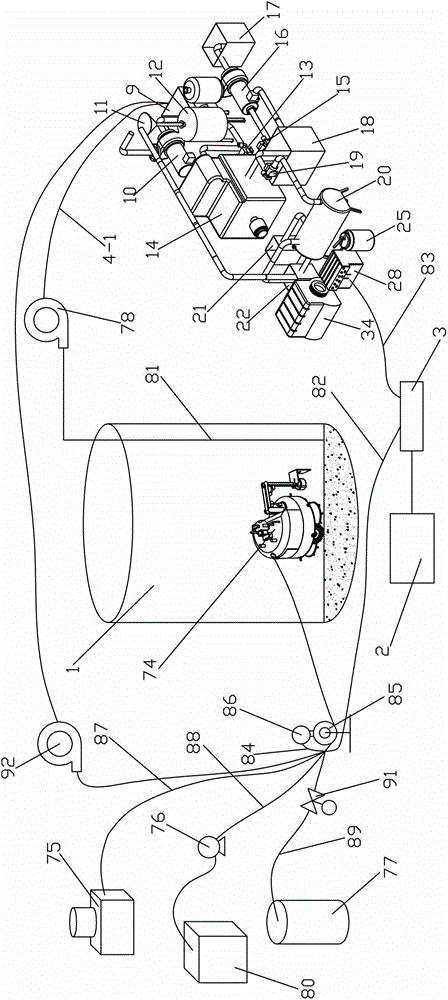

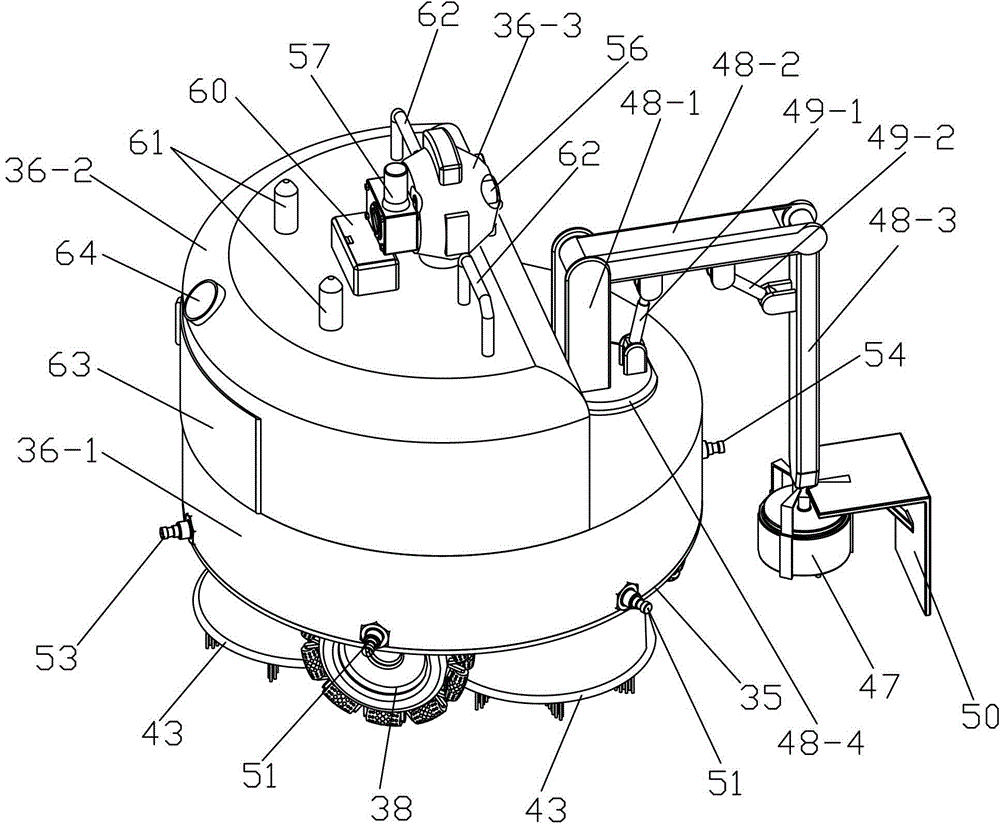

[0121] Such as figure 1 with Figure 15 As shown, the present invention includes a cleaning system for cleaning the oil sludge in the oil tank 1 and an oil sludge treatment system for treating the oil sludge cleaned by the cleaning system, as well as an oil sludge treatment system for the cleaning system and the oil sludge treatment system. Comprehensive control system for comprehensive control;

[0122] The cleaning system includes a cleaning robot 74 for putting into the oil tank 1 and cleaning the oil sludge in the oil tank 1, an electric hydraulic pump 75 for providing hydraulic driving force for the cleaning robot 74, connected with the water tank 80 and using The water pump 76 used to provide the cleaning water flow for the cleaning robot 74, the inert gas storage tank 77 used to provide protective inert gas into the oil tank 1, and the oil sludge cleaned by the robot from the oil tank 1 to the oil sludge treatment system In the first screw pump 78, the cleaning robot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com