Supporting rod mechanism of forging press

A technology for supporting rods and forging presses, which is applied in forging/pressing/hammering machinery, forging/pressing/hammer devices, manufacturing tools, etc. high effect

Inactive Publication Date: 2012-12-19

徐静

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The object of the present invention is to provide a support rod mechanism for a forging press, which overcomes the disadvantages of the existing support rod mechanism, such as complex process and high cost when making spare parts for maintenance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

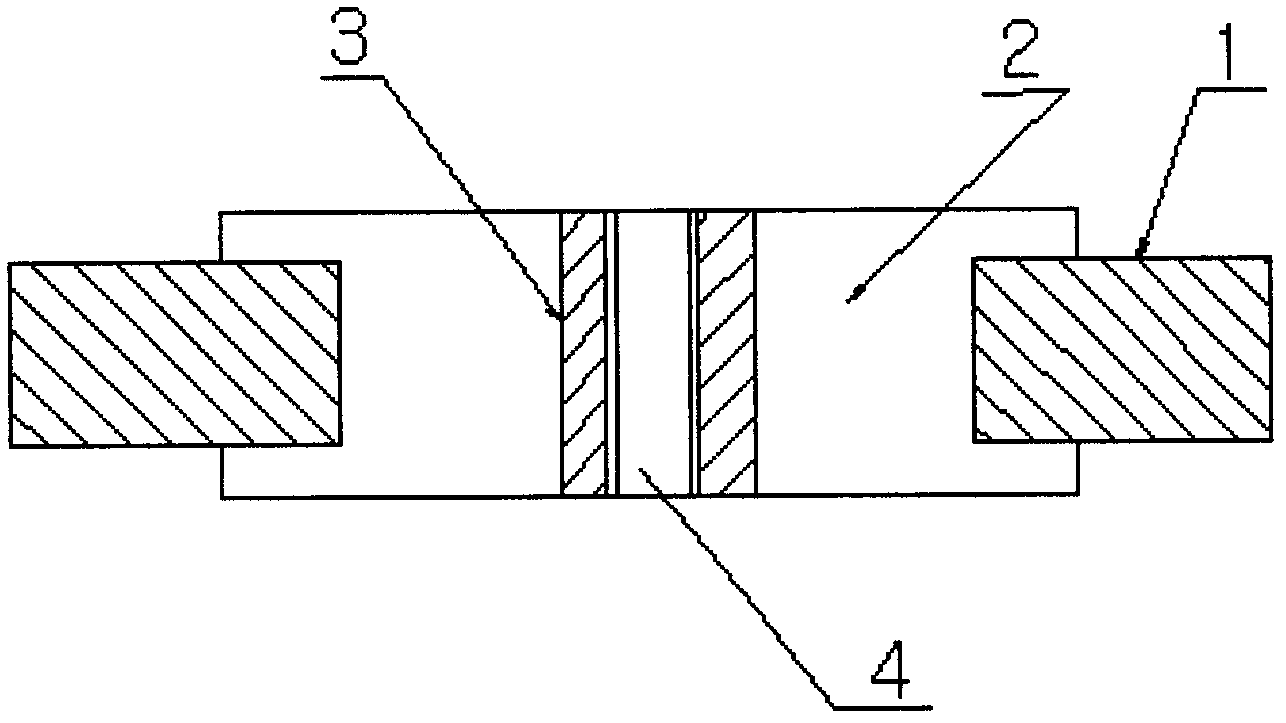

[0008] The support rod mechanism has a support rod joint 1 and two front and rear side plates 2, and is shaped on a screw rod 4 on the nut 3, and the support rod joint 1 and the two front and rear side plates 2 nuts 3 are welded into an integral press support rod.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A supporting rod mechanism of a forging press is provided with a supporting rod joint, a front side plate and a rear side plate. A screw is arranged on a nut, and the supporting rod joint is welded with the front side plate and the rear side plate by the nut to form an integral supporting rod of the press. The supporting rod mechanism has the advantages that due to the structural form of a welding structural part, a manufacturing process of the supporting rod mechanism is quite simple, and the shortcoming that cost is high is overcome effectively.

Description

technical field [0001] The invention relates to a support rod mechanism, in particular to a forging press support rod mechanism, and belongs to the technical field of component structures of presses. Background technique [0002] At present, in the products of tilting presses, the structure of the supporting rod used to support the adjusting screw rod in the inclination mechanism is cast. This manufacturing method is not only complicated in the process of making maintenance parts , and the cost is higher. Contents of the invention [0003] The object of the present invention is to provide a support rod mechanism for a forging press, which overcomes the defects of complicated process and high cost in making spare parts for maintenance in the existing support rod mechanism. [0004] The technical scheme adopted by the present invention to solve its technical problems is: a kind of support rod mechanism of forging press, it is a support rod joint and two front and rear side ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B21J13/00

Inventor 徐静

Owner 徐静

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com