Automatic capped fastener positioner

An automatic positioning and fastener technology, applied in the direction of operating devices, forging/pressing/hammer devices, metal processing equipment, etc., can solve the problems of losing accurate positioning and unable to realize continuous mass production, and achieve accurate positioning and convenient transmission , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

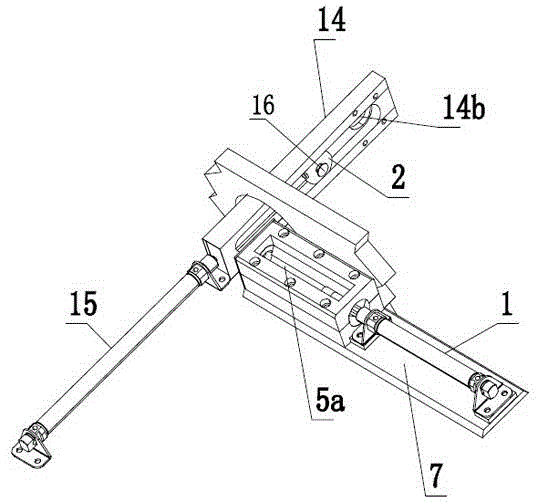

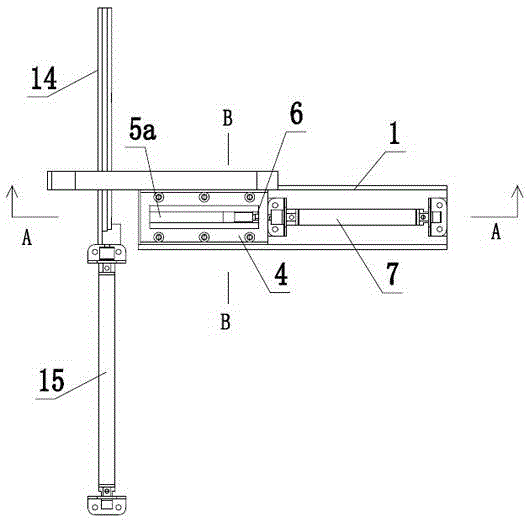

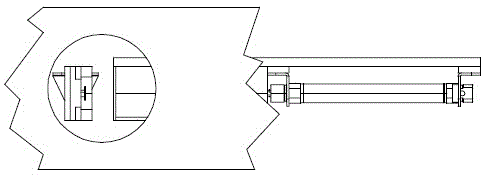

[0021] see Figure 1-Figure 8 , the automatic positioning device for capped end fasteners in this embodiment includes a bottom plate 1, a guide seat, a push assembly, a guide assembly, a positioning block 2 and an automatic moving member, and the guide seat includes an insert seat 3, an insert press plate 4 and a guide groove The insert 5, the insert seat 3 is fixed on the base plate 1, the guide groove The insert 5 is provided with a guide groove 5a, the guide groove 5a is in a cylindrical structure and has an opening 5b for the fastener 16 to be put in, the insert seat 3 is provided with an insert groove 3a, and the guide groove insert 5 snaps into the insert groove 3a, and is pressed and fixed by the insert press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com