Pouring system with gate runner

A pouring system and runner technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of easy generation of mesh wires in castings and high cost, achieve good slag blocking effect, save costs, and facilitate promotion Applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings of the description.

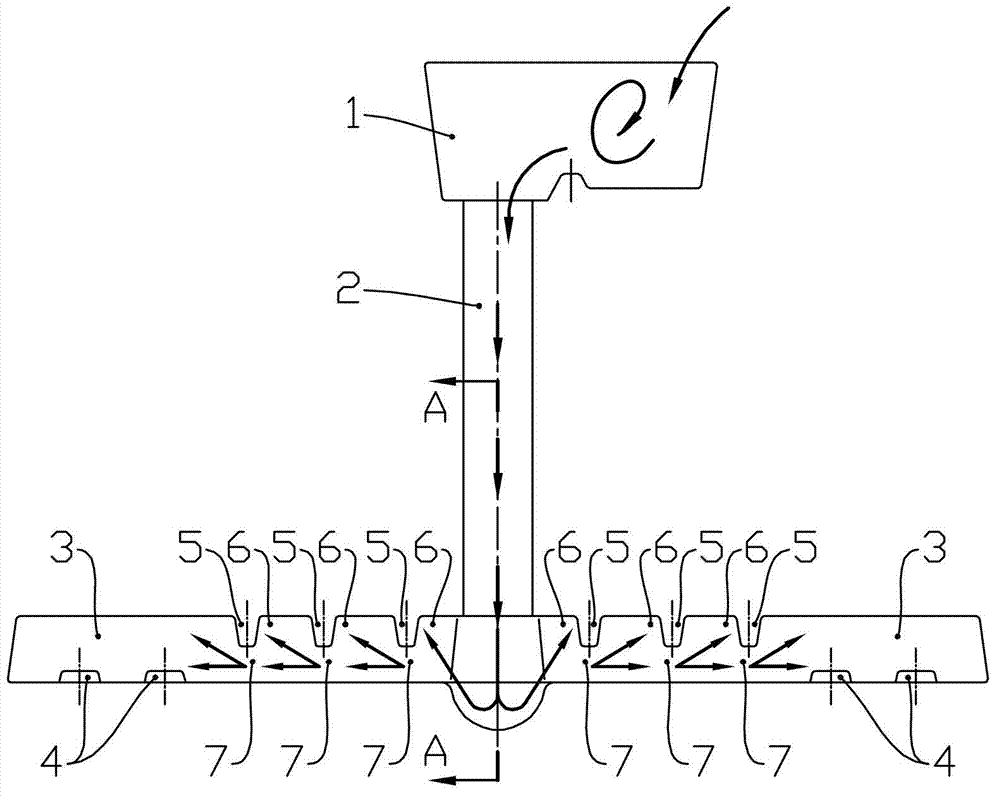

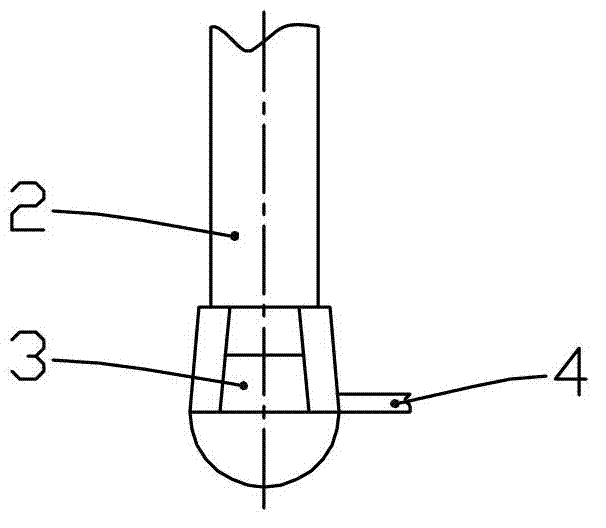

[0015] The gating system with the gate runner of the present invention, such as figure 1 , 2 As shown, it includes an outer sprue 1, a sprue 2, a runner 3, and an inner runner 4 connected in sequence. The top of the runner 3 is provided with a gate 5, and the front side of the gate 5 forms a slag retention space 6. , The lower side of the gate 5 forms a runner 7 with a reduced cross-sectional area. Further, there are multiple gates 5 distributed along the extending direction of the runner. The gate 5 is a ridge extending downward from the top of the runner.

[0016] The gate 5 of the present invention can be made directly on the wooden mold of the runner, and it can be formed together with the casting mold when the sand is placed in the molding, which can save the cost of purchasing the filter residue sheet, and the economic benefit is obvious (to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com