Fully-automatic net cutting machine for two-way stretching plastic side protection net

A two-way stretching and fully automatic technology, applied in the field of net cutting machine, can solve the problems of not cutting edges near the grid nodes, irregular cutting edges, and personnel disabilities, etc., achieving high degree of automation, neat cutting edges, and reducing injuries. The effect of residual

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

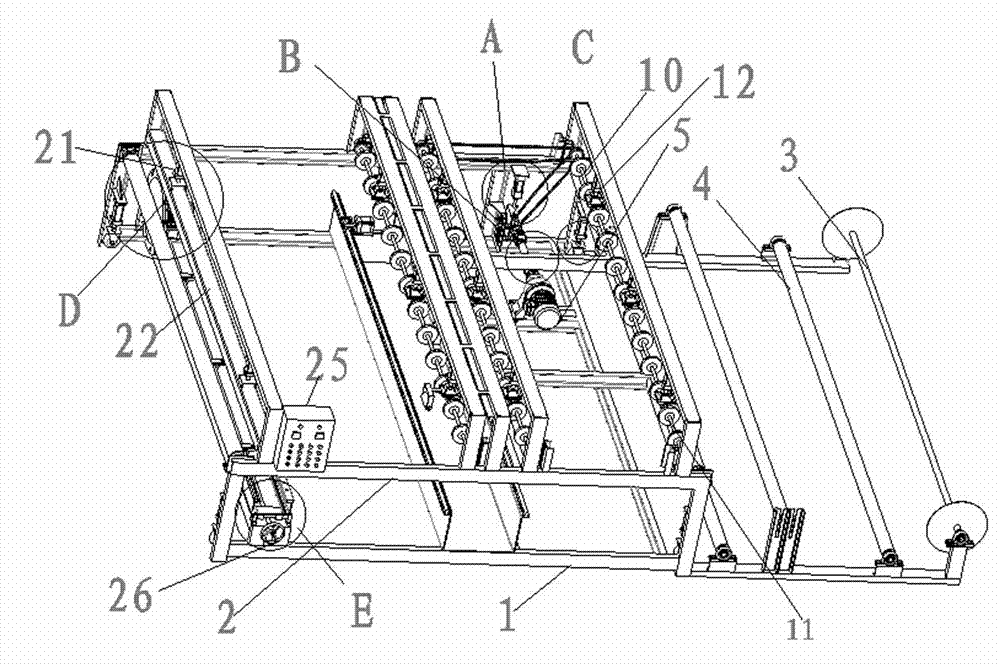

[0031] Such as figure 1 , 2 , 3, 4, 5, and 6 show a biaxially stretched plastic mutual net automatic cutting machine, including a support frame 2, a workbench 1, a net roll fixing frame, and a support net are installed on the support frame 2 device, vertical net cutting device, horizontal net cutting clamping and net cutting device;

[0032] The net roll fixing frame includes a net roll fixing shaft 3 and a grid adjustment shaft 4, wherein the net roll fixing shaft 3 is fixed at the end of the support frame 2, and the grid adjustment shaft 4 is fixed at the end of the net roll fixing shaft 3 ahead;

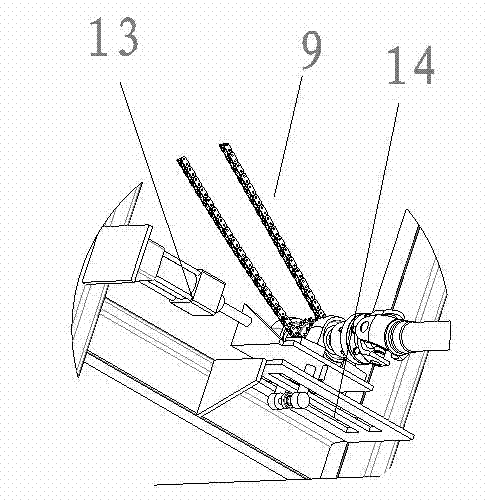

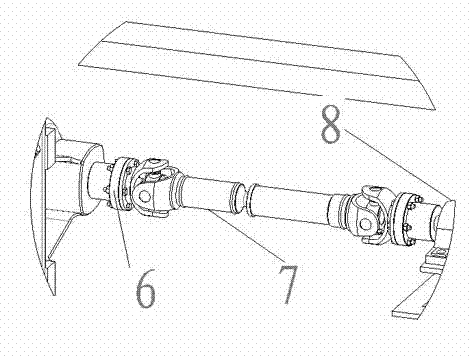

[0033] Described side guard net advancing device comprises speed reducer 5, cylinder, gear shaft 8 and roller shaft 10, and described speed reducer 5 is connected with gear shaft 8 through coupling 7, and is fixed on the below of workbench 1, and cylinder Ⅰ13 is vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com