Chamfering and edge folding device and production process of all-paper packaging barrel

A technology of folding equipment and packaging drums, which is applied in packaging, transportation and packaging, paper/cardboard containers, etc., and can solve problems such as the inability to meet the demand for large-scale supply in short construction periods, uneven quality of finished products, and high technical level requirements. , to achieve the effect of constant quality, high processing precision and guaranteed processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

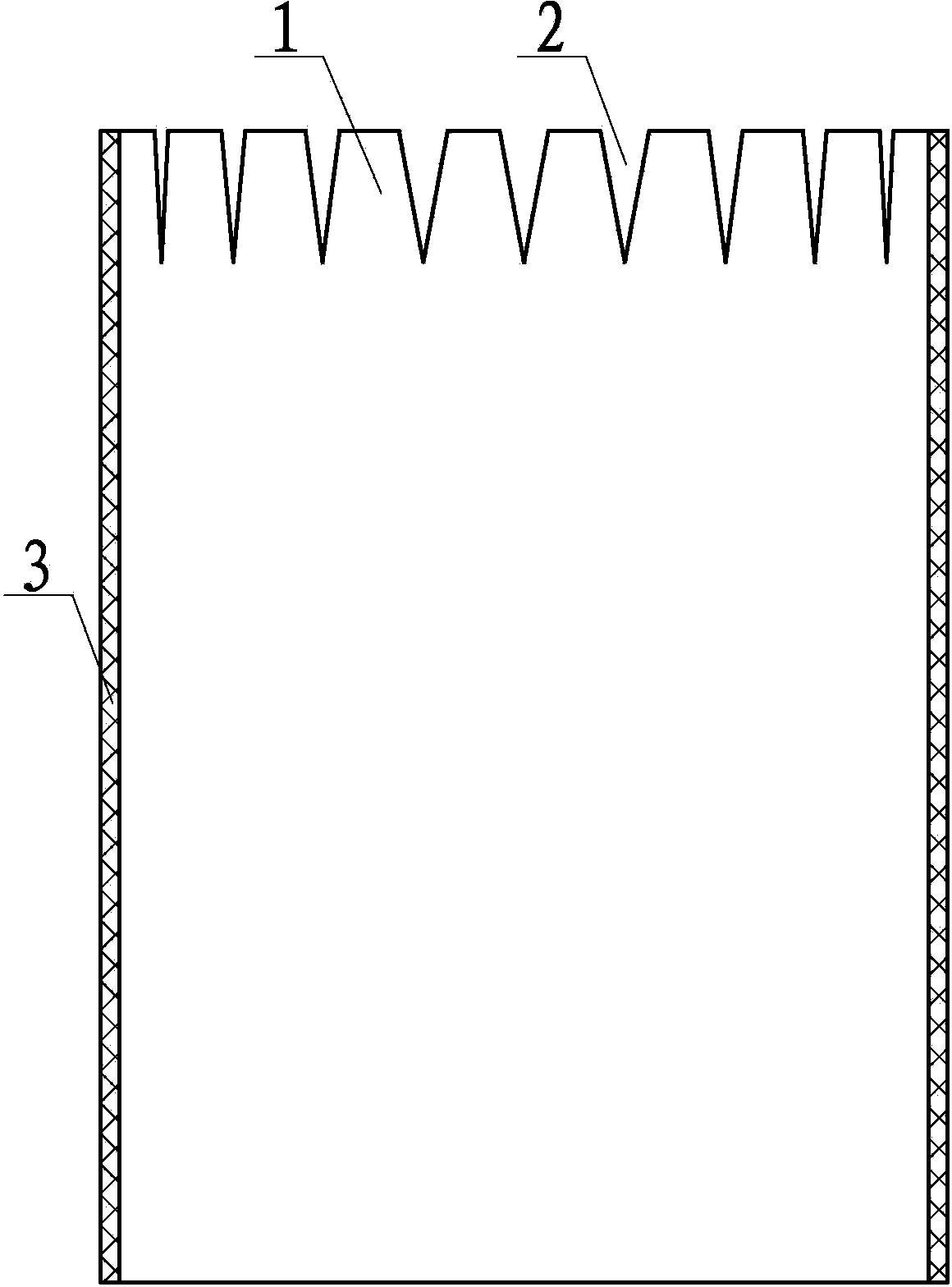

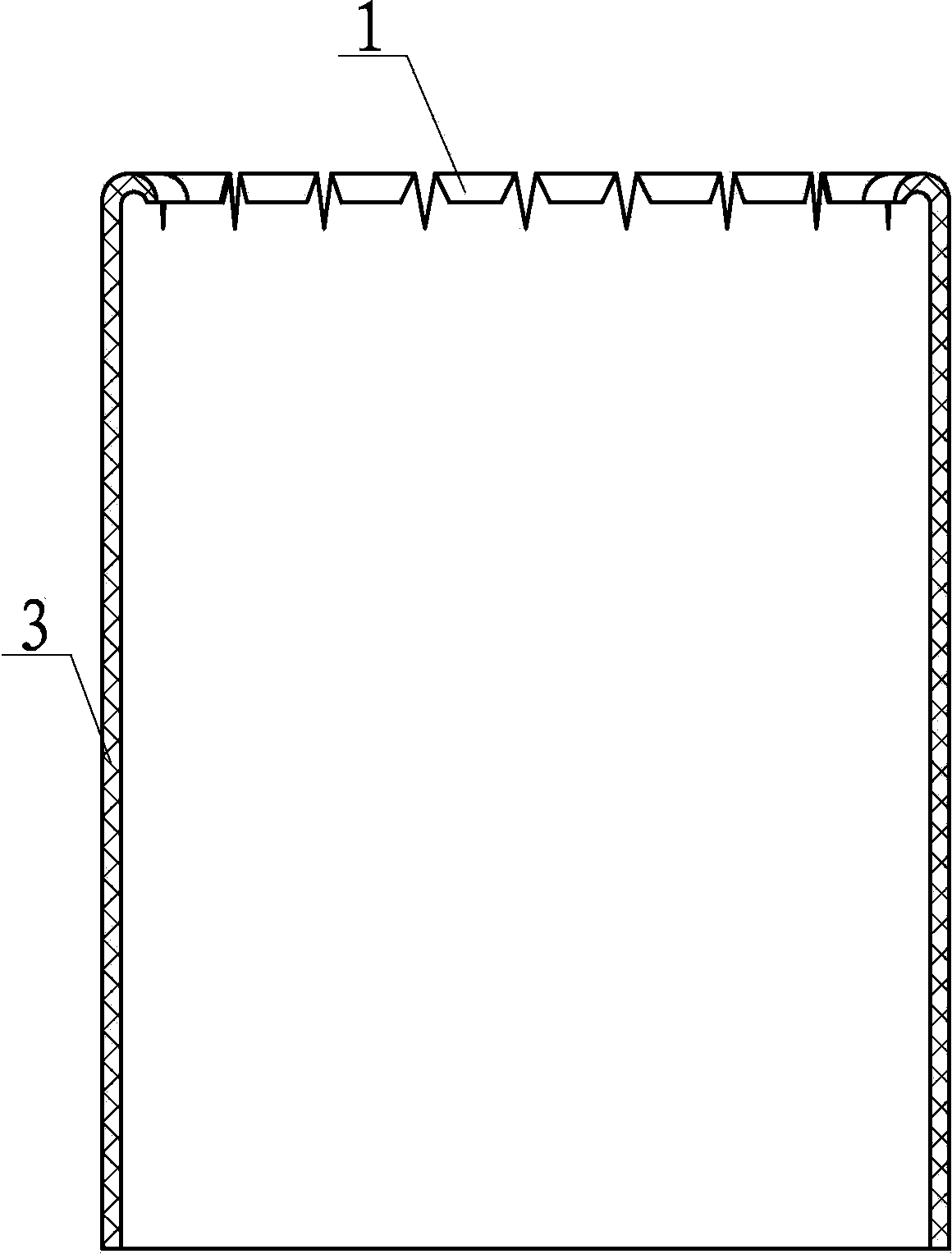

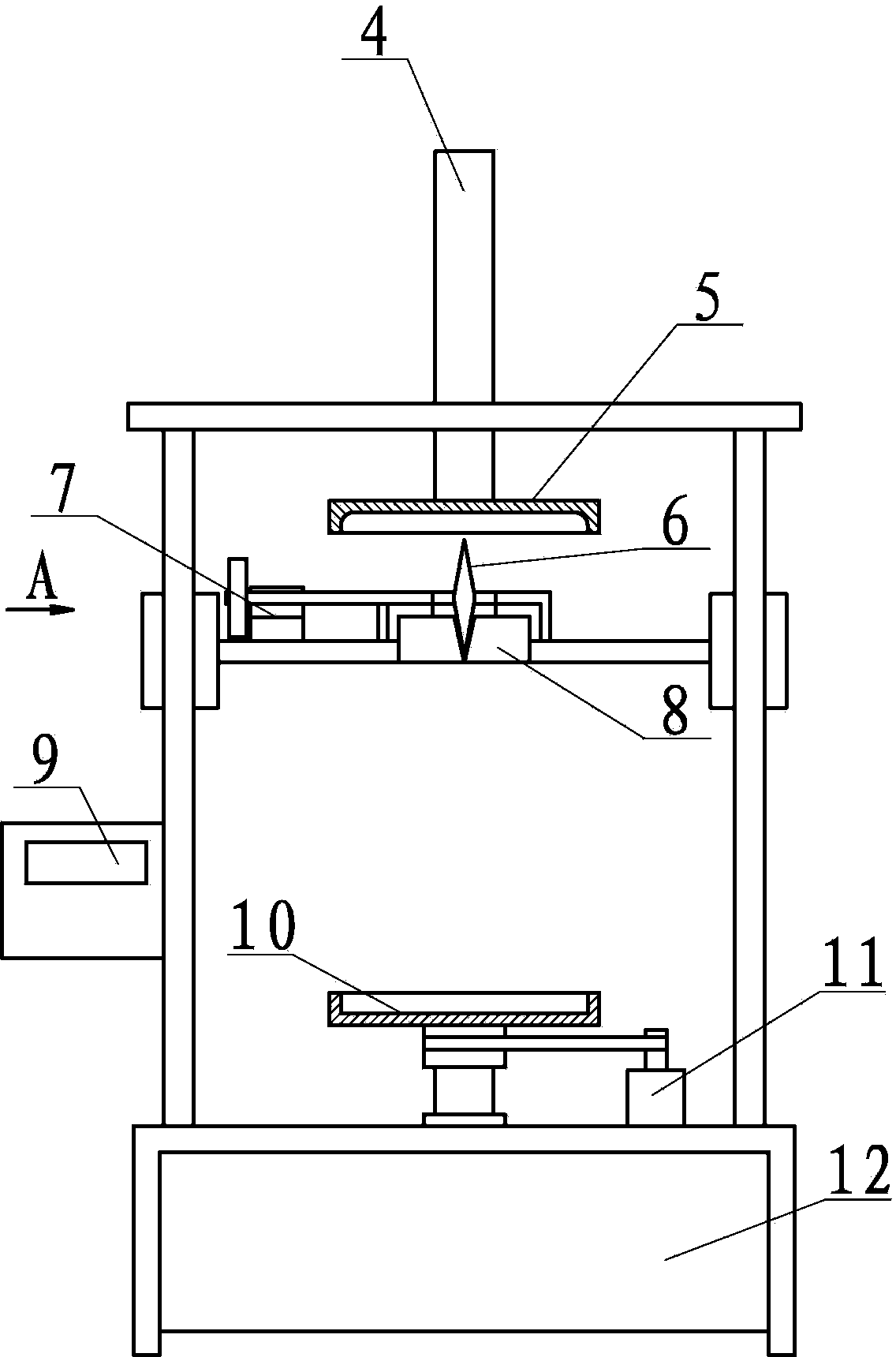

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0034] As shown in the figure, the corner-folding equipment for a full-paper packaging bucket according to the present invention is equipped with a disc-shaped base 10 at the bottom of the frame 12, and the base 10 is connected to the rotating device 11 through a belt, and is driven by the rotating device 11 The base 10 rotates by itself, and the rotation control device can adopt a numerically controlled motor. Lifting device 4 is installed on the top of frame 12, and lifting device 4 can adopt air cylinder or hydraulic oil cylinder, and lifting device 4 connects hemming device 5, and hemming device 5 is the disc body that has offered hemming groove, and hemming groove The perimeter of is rounded. The hemming device 5 is installed coaxially with the base 10 , and the grooved surface of the hemming device 5 faces the base 10 .

[003...

Embodiment 2

[0043] The lifting device 4 can also be connected to the base 10, so that the base 10 is controlled to drive the barrel body 3 to move upward, and the bottom of the barrel is squeezed into the hemming device 5 to complete the hemming. Other structures and processing steps are the same as those in Embodiment 1 and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com