Torque control method of automobile four-drive system

A torque control and automotive technology, applied in the automotive field, can solve the problems of high fuel consumption and poor economy, and achieve the effects of ensuring power, improving fuel economy and riding comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

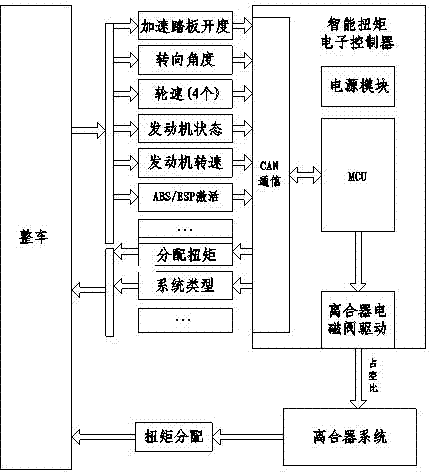

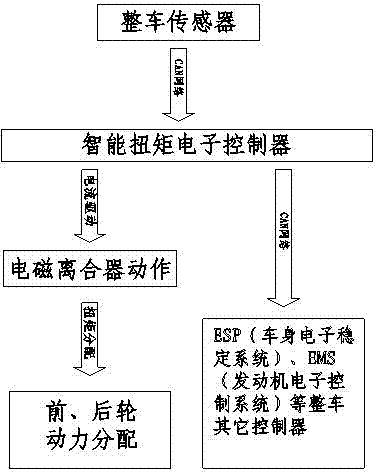

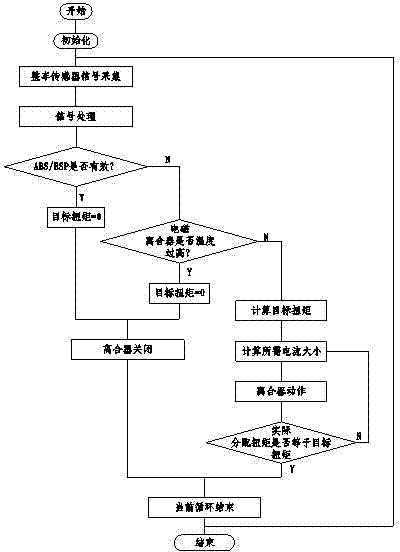

[0027] The intelligent torque electronic controller used in the present invention needs to cooperate with vehicle sensors, CAN bus, electromagnetic clutch, ABS (anti-lock braking system) / ESP (body electronic stability system), etc. to realize the time-sharing conversion of two-wheel drive / four-wheel drive. For the system block diagram and structural block diagram, see figure 1 , figure 2 .

[0028] The intelligent torque electronic controller is an electronic control unit that uses existing body sensors to receive signals such as accelerator pedal opening, steering angle, wheel speed, engine status, engine speed, and ABS / ESP activation through the CAN bus to determine the driving status of the vehicle , calculate the torque that needs to be transmitted to the rear wheels through the control strategy, and send the distribution torque, system type and other signals to the vehicle network through the CAN bus, and at the same time, the clutch solenoid valve drive module outputs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com