Horizontal tail of double-swept back full dynamic deflection aircraft

A swept-back and flat-tail technology, applied in the field of double-swept full-motion deflection aircraft, can solve problems such as the decline of the aircraft's full-motion horizontal tail efficiency, the limitation and loss of the pitch control performance of the flat tail, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

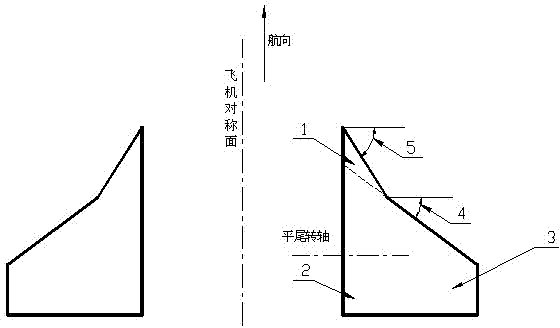

[0014] Specific embodiments of the present invention: as figure 1 Shown, a kind of double-sweep type full-motion deflection plane tail, comprises flat tail inner side 2, flat tail outer side 3 and rear segment sweep angle 4, is characterized in that it also includes the front segment swept wing 1 that is positioned at the front part of the flat tail and is formed by the front segment rear The front sweep angle 5 formed by the swept wing 1.

[0015] The shape of the leading edge of the swept wing 1 in the front section is sharp, and an ordered vortex with sufficient energy is generated at a large angle of attack to suppress the flow separation of the main airfoil of the outer section of the flat tail; the sweep angle 5 of the front section of the flat tail and the sweep angle of the rear section 4 are not equal, and the sweep angle 5 of the leading edge of the horizontal tail is generally 50° to 70°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com