Mesoporous hydroxyapatite nonoparticles prepared by microwave-ultrasonic method, and application thereof

A mesoporous hydroxyapatite and nanoparticle technology, applied in the field of materials science, can solve the problem of serious particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] In one embodiment of the present invention, a kind of preparation method of mesoporous hydroxyapatite nanoparticles is provided, comprising the following steps:

[0058] (a) Prepare Ca(NO 3 ) 2 and (NH 4 ) 2 HPO 4 aqueous solution, and using ammonia to (NH 4 ) 2 HPO 4 The pH of the aqueous solution is adjusted to 9-12;

[0059] (b) the above (NH 4 ) 2 HPO 4 solution and Ca(NO 3 ) 2 Mix quickly; then pour the mixed solution into the ultrasonic microwave reactor;

[0060] (c) Simultaneously turn on the ultrasonic microwave instrument to react for a certain period of time;

[0061] (d) Centrifuge the reaction solution, wash it twice with deionized water, and wash it twice with ethanol; then directly put it into a freeze dryer and freeze-dry it for 24 hours;

[0062] (e) Put the sample into a muffle furnace and calcinate for 5 hours to obtain mesoporous hydroxyapatite nanoparticles.

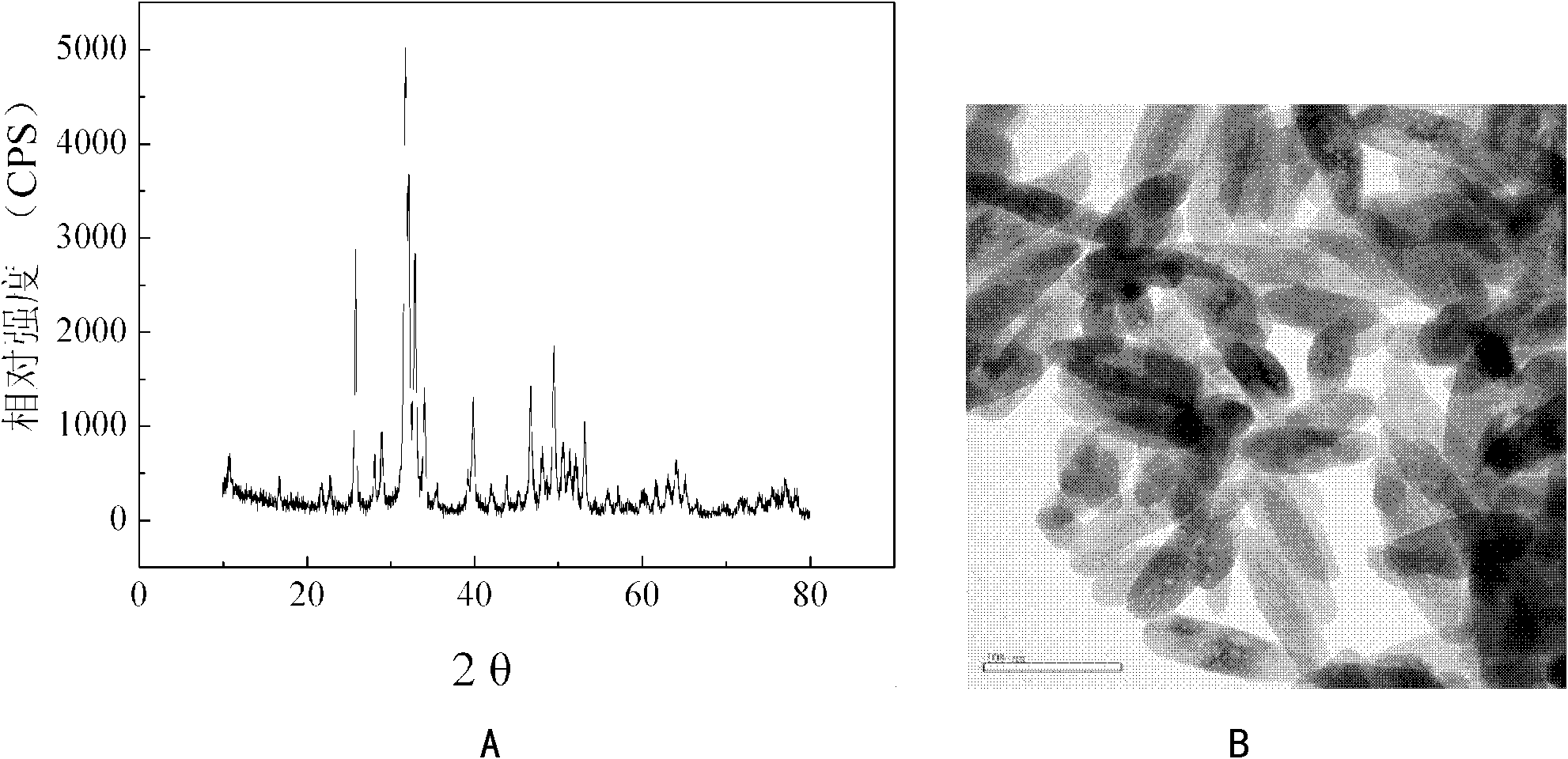

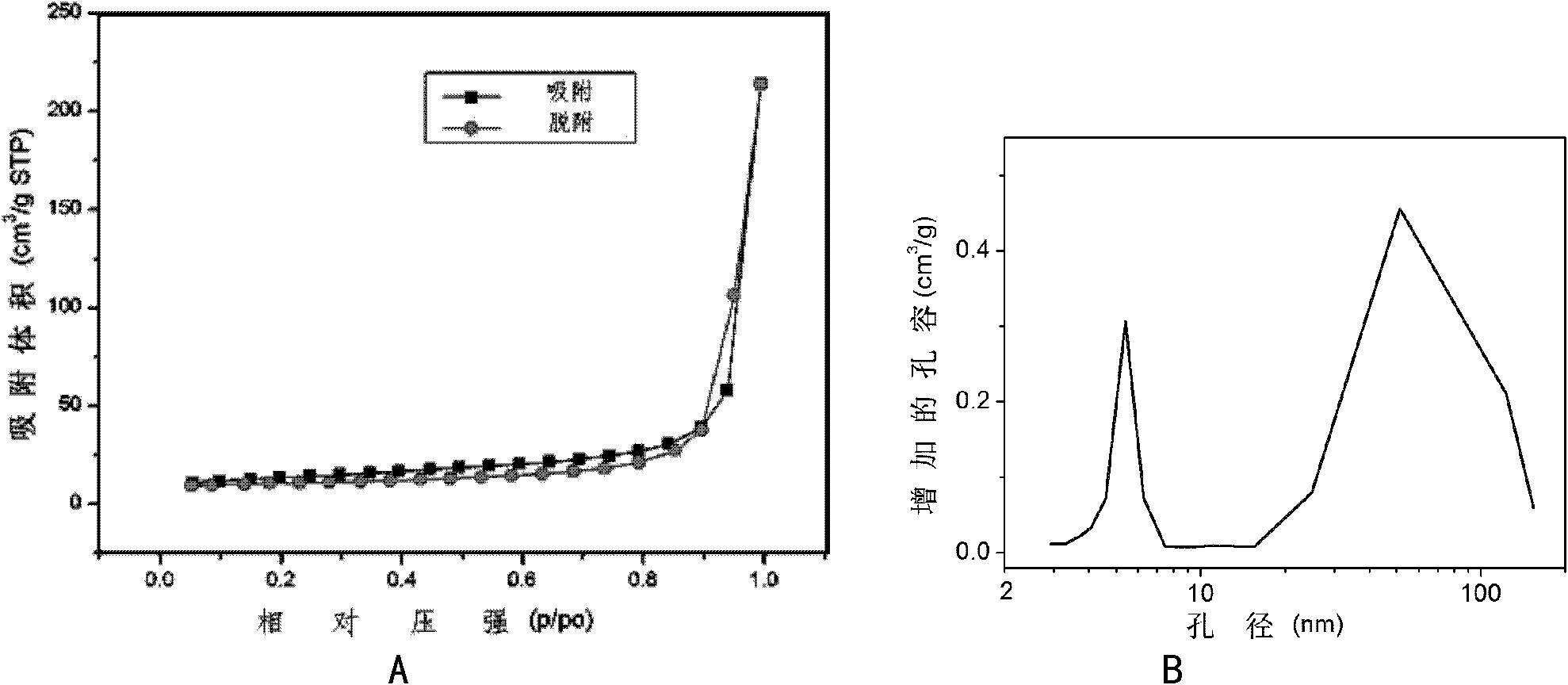

[0063] The mesoporous hydroxyapatite nano-particles prepared by the inventi...

Embodiment 1

[0076] Embodiment 1, preparation of mesoporous hydroxyapatite nanoparticles 1

[0077] Weigh 2.36 g of Ca(NO 3 ) 2 and 0.79 g (NH 4 ) 2 HPO 4 (Ca / P (molar ratio) = 1.67), were dissolved in 50mL and 30mL of deionized water, and adjusted with ammonia water (NH 4 ) 2 HPO 4 solution to 10; the above (NH 4 ) 2 HPO 4 The solution was rapidly added Ca(NO 3 ) 2 Mix in the solution; then pour the mixed solution into the ultrasonic microwave reactor, turn on the ultrasonic microwave instrument at the same time, set the power of ultrasonic and microwave to 200w, and react at 60°C for 30min. Then the reaction solution was centrifuged to remove the supernatant, and the obtained precipitate was washed twice with deionized water and twice with ethanol; then it was directly placed in a freeze dryer for 24 hours; finally, the sample was placed in a muffle furnace for calcination for 5 hours , to obtain mesoporous hydroxyapatite nanoparticles.

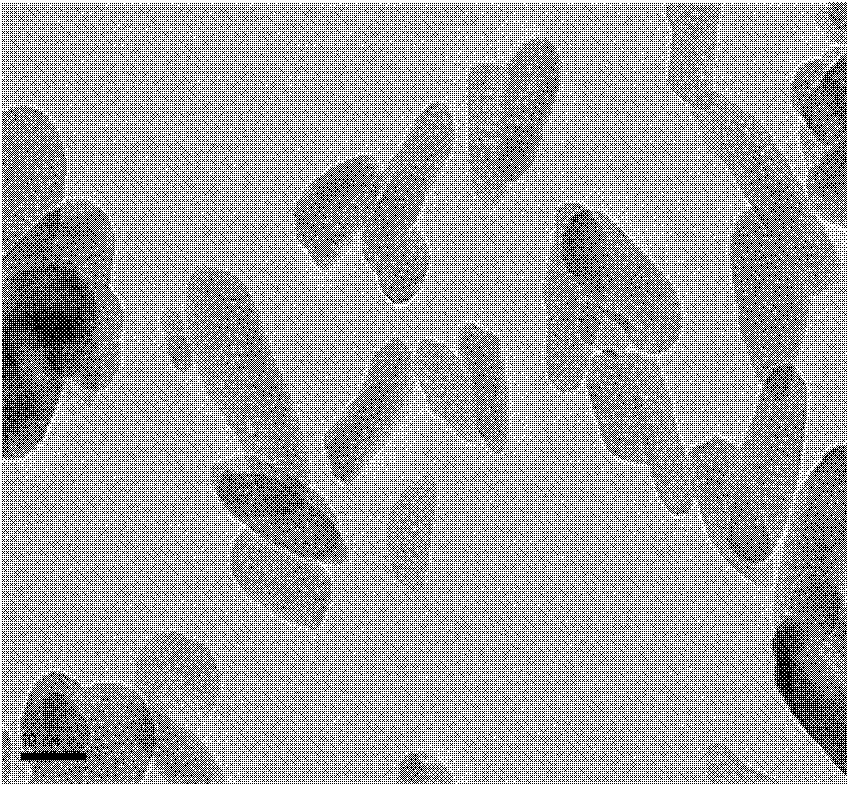

[0078] The obtained mesoporous mater...

Embodiment 2

[0080] Embodiment 2, preparation 2 of mesoporous hydroxyapatite nanoparticles

[0081] Weigh 2.72 g of CaSO 4 and 1.38 g NH 4 h 2 PO 4 , respectively dissolved in 50mL and 30mL of deionized water, and adjusted NH with ammonia water 4 h 2 PO 4 solution to pH9.5; the above NH 4 h 2 PO 4 The solution was rapidly added with CaSO under stirring 4Mix in the solution; then pour the mixed solution into the ultrasonic microwave reactor, turn on the ultrasonic microwave instrument at the same time, set the power of ultrasonic and microwave to 50w and 200w respectively, and react at 60°C for 30min. Then the reaction solution was centrifuged to remove the supernatant, and the obtained precipitate was washed twice with deionized water and twice with ethanol; then it was directly placed in a freeze dryer for 24 hours; finally, the sample was placed in a muffle furnace for calcination for 5 hours , to obtain mesoporous hydroxyapatite nanoparticles.

[0082] The obtained mesoporous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com