Biomedical anhydrous Ca(HPO4)x(SO4)(1-x) solid solution granule and preparation method thereof

A HPO42-, biomedical technology, applied in the direction of chemical instruments and methods, applications, prostheses, etc., can solve the problems of narrow application range, inability to apply injectable bone repair materials, etc., achieve simple operation, good clinical application prospects, The effect of easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

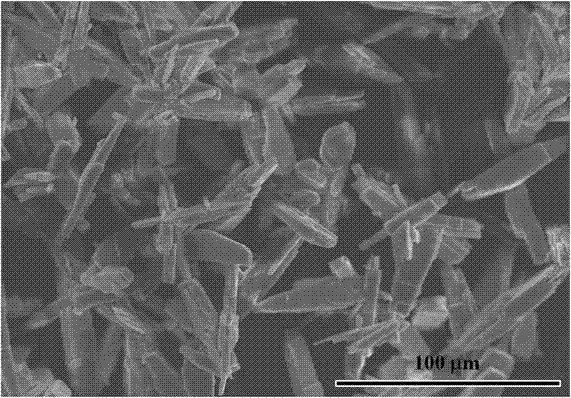

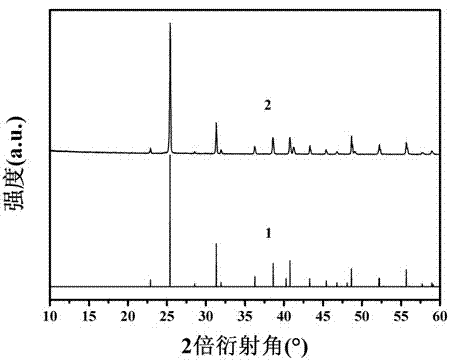

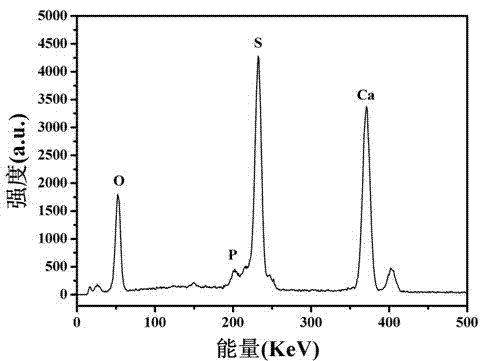

Image

Examples

Embodiment 1

[0020] 1) Add CaCl 2 and K 2 SO 4 Dissolved in deionized water, respectively prepared into solutions, mixed at room temperature according to the molar ratio of Ca / S of 1:1, the reaction was carried out under constant stirring, the reaction temperature was room temperature, and the reaction time was 2 hours. After the reaction, use Filter 3 times with deionized water, once with alcohol, and then dry at 60°C to obtain CaSO 4 2H 2 O;

[0021] 2) Dissolve 0.4g of citric acid monohydrate in 400ml of deionized water to make an electrolyte solution;

[0022] 3) 10g of CaSO obtained in step 1) 4 2H 2 0 and the electrolyte solution prepared in step 2) are mixed to obtain a suspension;

[0023] 4) Add 1g of CaHPO 4 2H 2 O and the suspension prepared in step 3) are stirred and mixed, then put into the reaction kettle, so that the molar ratio of P / S in the mixed solution is 0.1, and the reaction is carried out under the hydrothermal condition of 130°C, and the reaction time is 5 ...

Embodiment 2

[0025] 1) CaNO 3 and K 2 SO 4 Dissolved in deionized water, respectively prepared into solutions, mixed at room temperature according to the molar ratio of Ca / S of 1:1, the reaction was carried out under constant stirring, the reaction temperature was room temperature, and the reaction time was 2 hours. After the reaction, use Filter 3 times with deionized water, once with alcohol, and then dry at 60°C to obtain CaSO 4 2H 2 O;

[0026] 2) Dissolve 0.4g of citric acid monohydrate in 400ml of deionized water to make an electrolyte solution;

[0027] 3) 10g of CaSO obtained in step 1) 4 2H 2 0 and the electrolyte solution prepared in step 2) are mixed to obtain a suspension;

[0028] 4) Add 4.16g of Na 2 HPO 4 12H 2 O and the suspension prepared in step 3) are stirred and mixed and then put into the reaction kettle so that the molar ratio of P / S in the mixed solution is 0.2, and the reaction is carried out under the hydrothermal condition of 140°C, and the reaction time...

Embodiment 3

[0033] 1) Add CaCl 2 and Na 2 SO 4 Dissolved in deionized water, respectively prepared into solutions, mixed at room temperature according to the molar ratio of Ca / S of 1:1, the reaction was carried out under constant stirring, the reaction temperature was room temperature, and the reaction time was 2 hours. After the reaction, use Filter 3 times with deionized water, once with alcohol, and then dry at 60°C to obtain CaSO 4 2H 2 O;

[0034] 2) Dissolve 0.4g of citric acid monohydrate in 400ml of deionized water to make an electrolyte solution;

[0035] 3) 10g of CaSO obtained in step 1) 4 2H 2 O and the electrolyte solution prepared in step 2) are mixed to obtain a suspension;

[0036] 4) Add 2.37g of KH 2 PO 4 Stir and mix the suspension prepared in step 3) and put it into the reaction kettle so that the molar ratio of P / S in the mixture is 0.3. The reaction is carried out under hydrothermal conditions at 150°C, and the reaction time is 3 hours. The reacted sample w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com