Gas divider/combiner with noise reduction function for compressor unit refrigeration system

A gas splitting and refrigeration system technology, applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problem of attenuation of refrigeration performance of compressor units, achieve the effects of attenuating fluid noise and simplifying the layout structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the following description, numerous specific details are given in order to provide a more thorough understanding of the present invention. It will be apparent, however, to one skilled in the art that the present invention may be practiced without one or more of these details. In other examples, some technical features known in the art are not described in order to avoid confusion with the present invention.

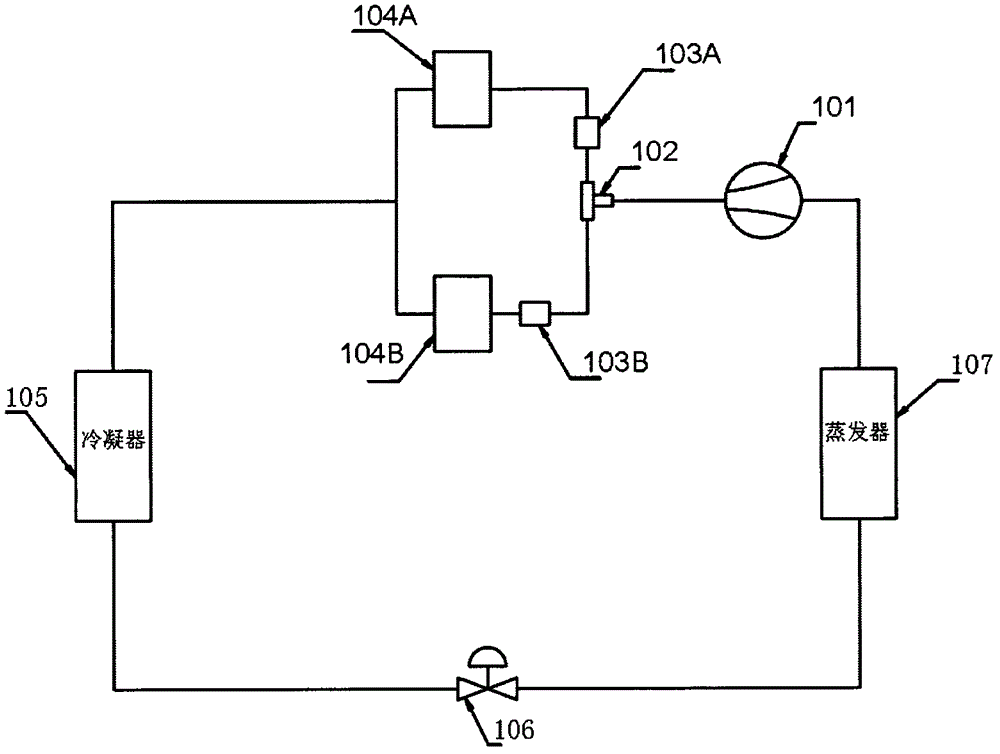

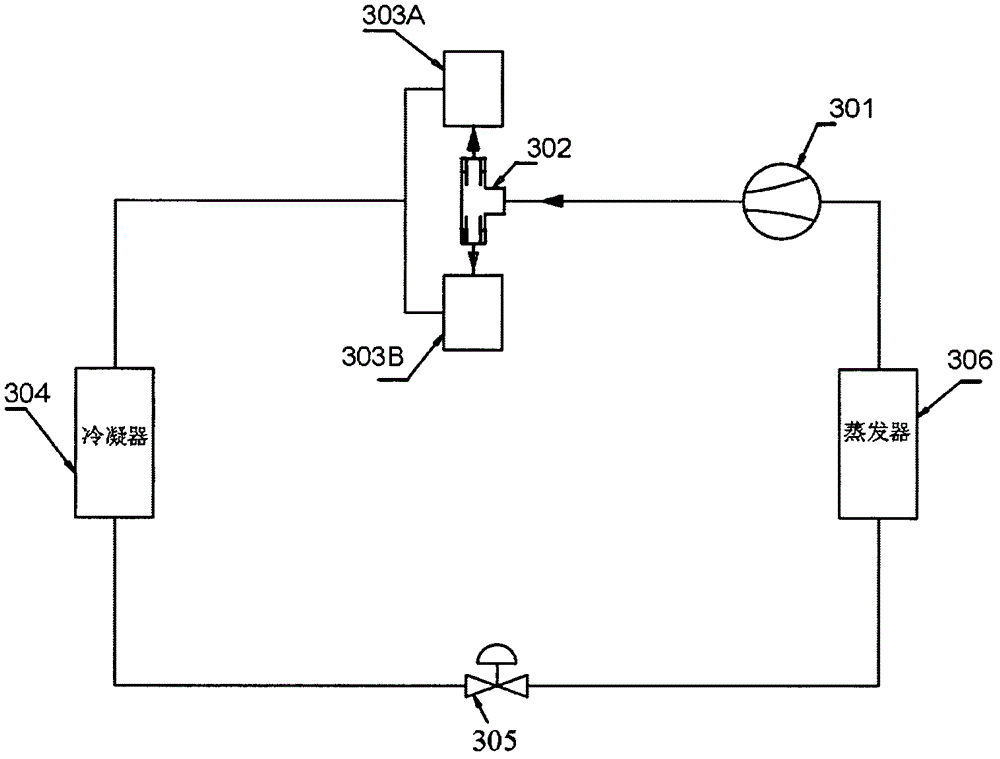

[0038] The present invention is applied in the refrigeration system of the compressor unit, and the overall system layout is as follows: Figure 3A and Figure 3B shown. Refrigeration systems with external oil separators such as Figure 3A As shown, the main components are: compressor 301, gas splitter 302 with noise reduction function, first oil separator 303A and second oil separator 303B, condenser 304, throttle valve 305, evaporator 306; Refrigeration systems with external oil separators such as Figure 3B As shown, the main components are: compressor 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com