Megawatt-level wind generating set paddle changing system battery automatic testing method and system

A technology for wind turbines and pitch systems, applied in the direction of measuring electrical variables, measuring electricity, measuring devices, etc., can solve the impact on safety and reliability, cannot monitor the battery status in real time, and the lead-acid battery cannot fully reflect the actual condition of the battery, etc. problems, to avoid potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

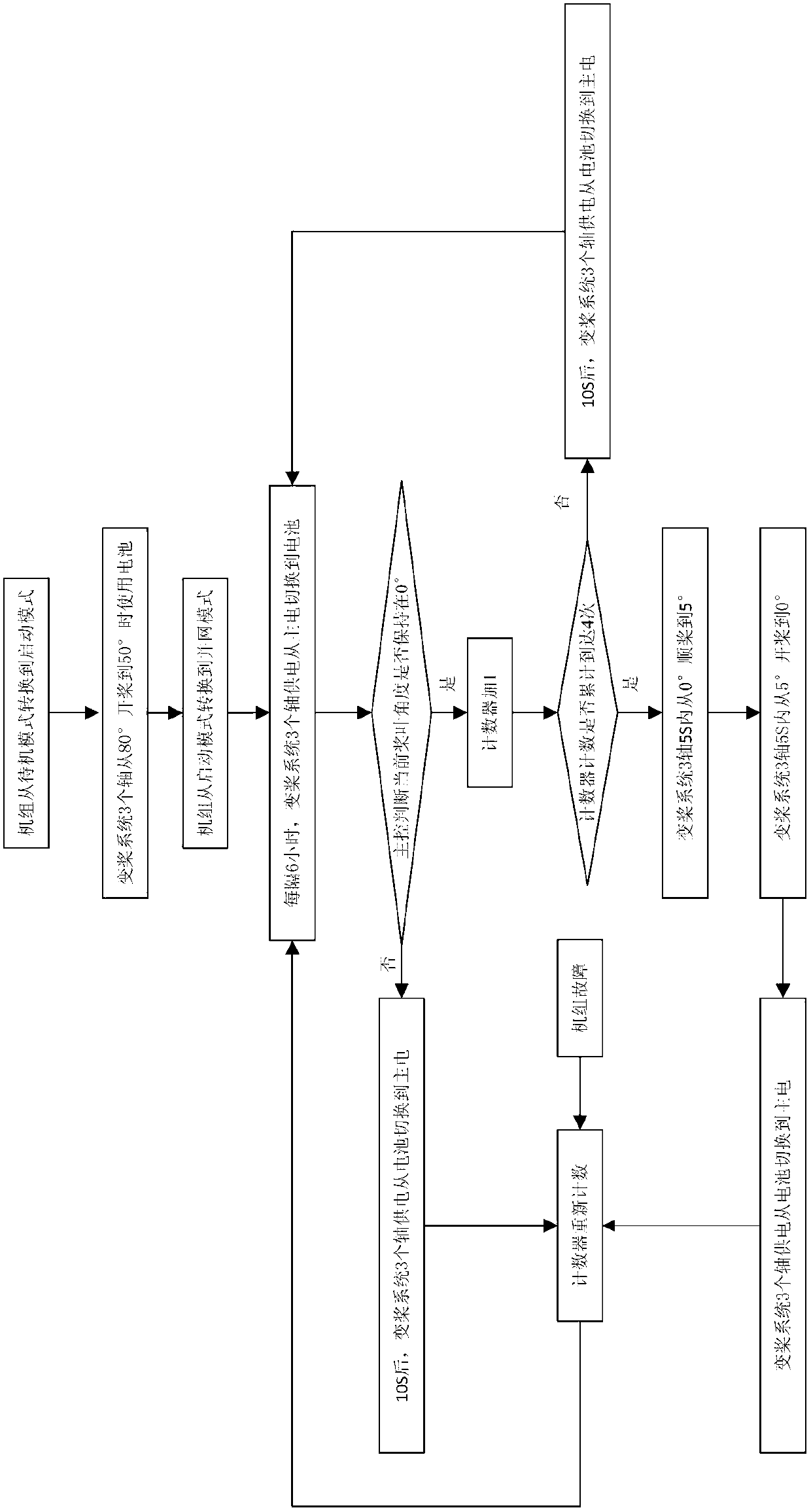

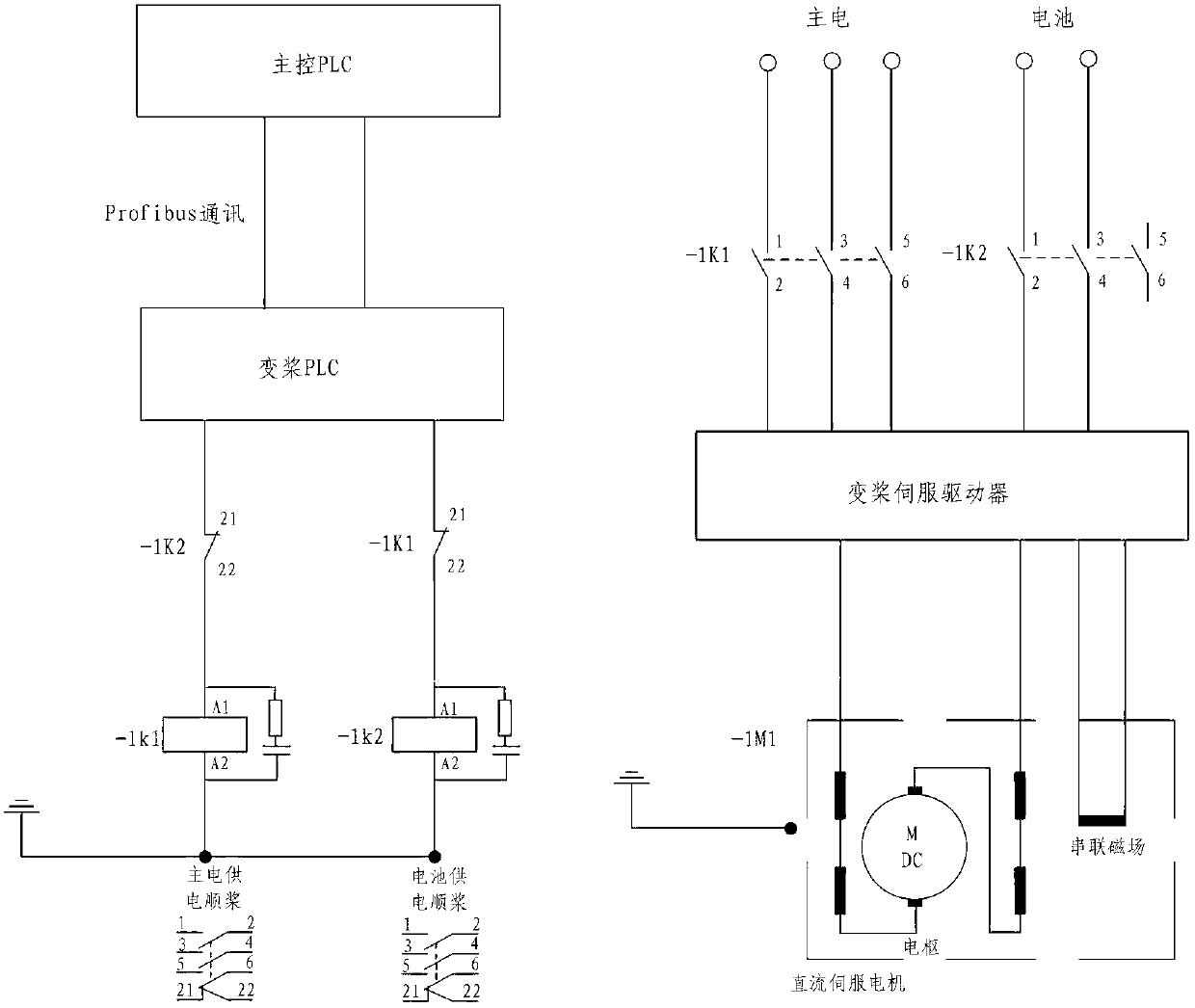

[0021] see figure 1 As shown, the present invention is an automatic battery test method for the pitch system of a megawatt-scale wind power generating set, including battery test in start-up mode and battery test in grid-connected mode.

[0022] Among them, when the unit is in the start-up mode, when the position command value sent by the main control to the pitch system is 80°, the main control sends a power supply switching command to the three axes of the pitch system at the same time, and the power supply of the pitch system is switched from the main power to the The battery powers on.

[0023] When the position command value sent by the main control to the pitch system is 50°, the main control simultaneously sends a power supply switch reset command to the three axes of the pitch system, and the power supply of the pitch system is switched from the battery to the main power supply.

[0024] When the unit changes from the start-up mode to the grid-connected mode, after th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com