Temperature control system for battery packs

A control system and battery pack technology, applied in battery pack components, secondary batteries, circuits, etc., can solve the problems of low convection heat transfer coefficient, poor battery heating effect, inconvenient maintenance and maintenance, and achieve uniform temperature change, Good isolation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

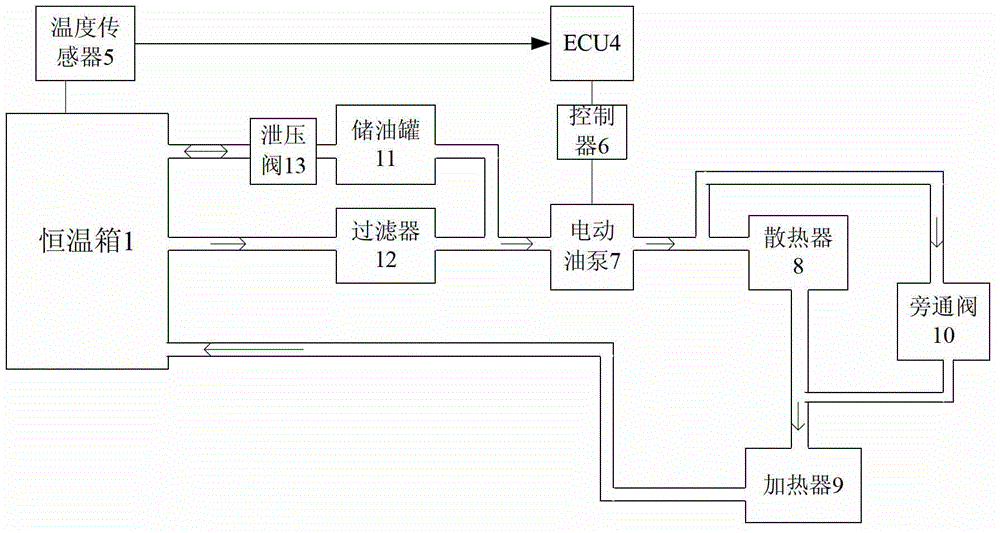

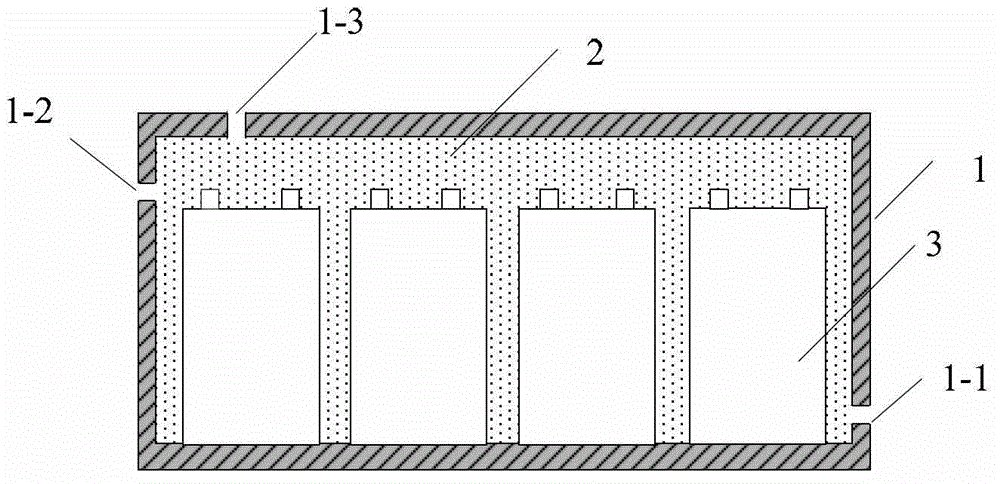

[0038] Such as figure 1 and figure 2 As shown, a battery pack temperature control system in this embodiment includes a battery pack 3, an ECU 4, a constant temperature box 1 filled with insulating oil, a radiator 8, a heater 9, an oil pump controller 6, an electric oil pump 7, an oil storage Tank 11 and oil filter 12, the insulating oil used in this embodiment is transformer oil.

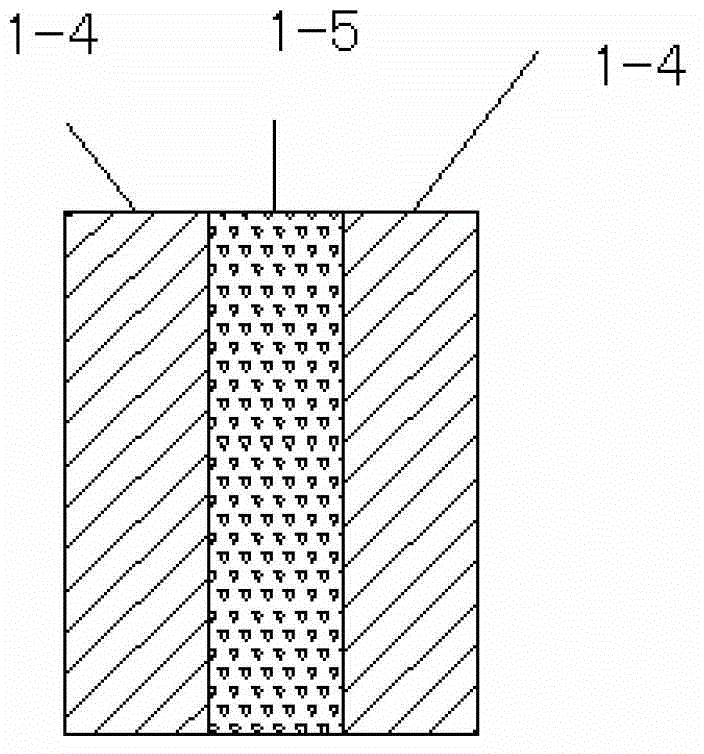

[0039] The battery pack 3 is completely immersed in the transformer oil 2 in the constant temperature box 1, which reduces the temperature difference generated by each part of the battery pack 3, makes the temperature change of each part of the battery pack 3 more uniform, and improves the thermal efficiency of the battery pack 3. At the same time, the transformer oil as the insulating oil can also play the role of insulation and arc extinguishing, preventing fire and burning when the battery leaks, and improving the safety of the system in this embodiment.

[0040] The constant temperature box 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com