Accurate positioning method of rotor of brushless direct-current motor for direct drive type washing machine

A brushed DC motor and precise positioning technology, which is applied to other washing machines, electronic commutators, applications, etc., to achieve the effect of simple method, convenient control and meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

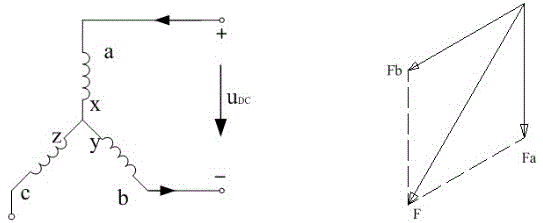

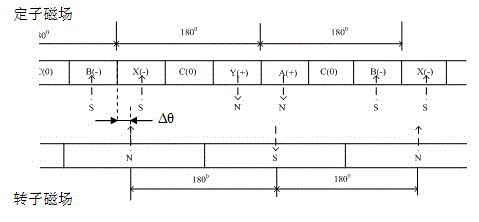

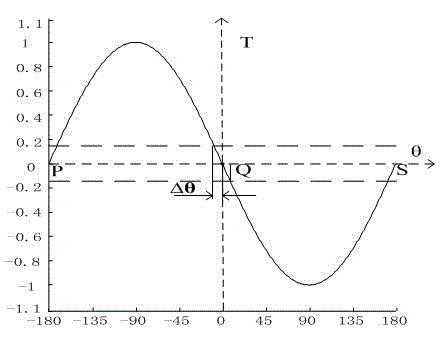

[0011] Such as Figure 1 ~ Figure 3 As shown, the precise positioning method for the rotor of a brushless DC motor used in a direct-drive washing machine involved in this embodiment, first, connect the stator part of the motor with the casing, and then assemble it on the washing machine, and determine the position of the stator of the motor. The spatial position of the winding; 2. To pass direct current to the A and B two-phase windings of the motor stator, and the synthetic magnetic potential generated by the A-phase and B-phase windings forms a magnetic field with a fixed direction in the stator; 3. According to the princ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com