Improved backdrilling of multilayer printed circuit boards

A technology of printed circuit boards and substrates, which is applied in the direction of printed circuits, printed circuit manufacturing, printed circuit components, etc., and can solve problems such as impact, small via hole to via hole spacing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] While the invention is susceptible to various modifications and alternative forms, specific embodiments thereof have been shown by way of example in the drawings and described in detail herein. It should be understood, however, that there is no intention to limit the invention to the particular forms disclosed, but the intention is to cover all modifications, equivalents, and alternatives falling within the scope and spirit of the invention.

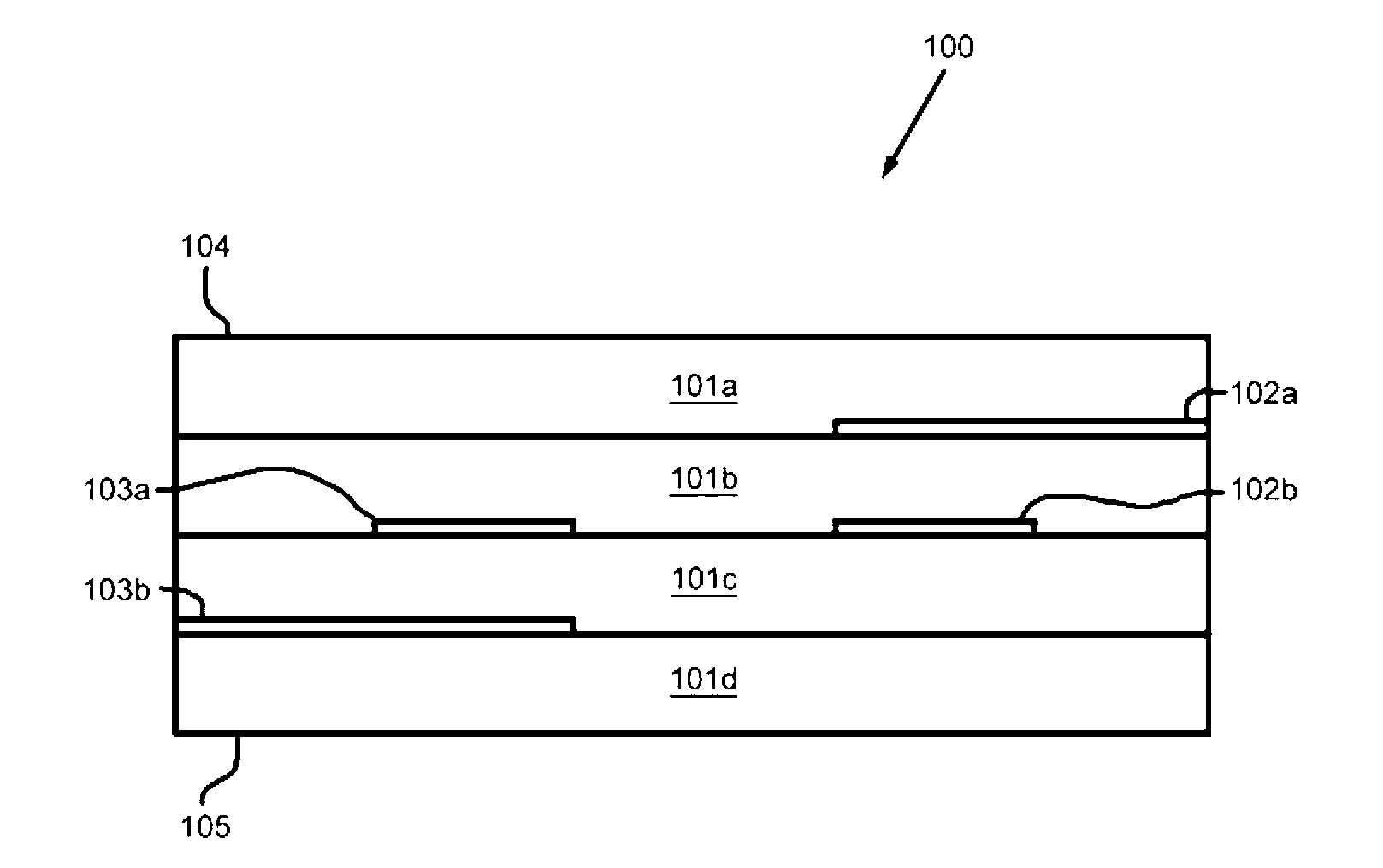

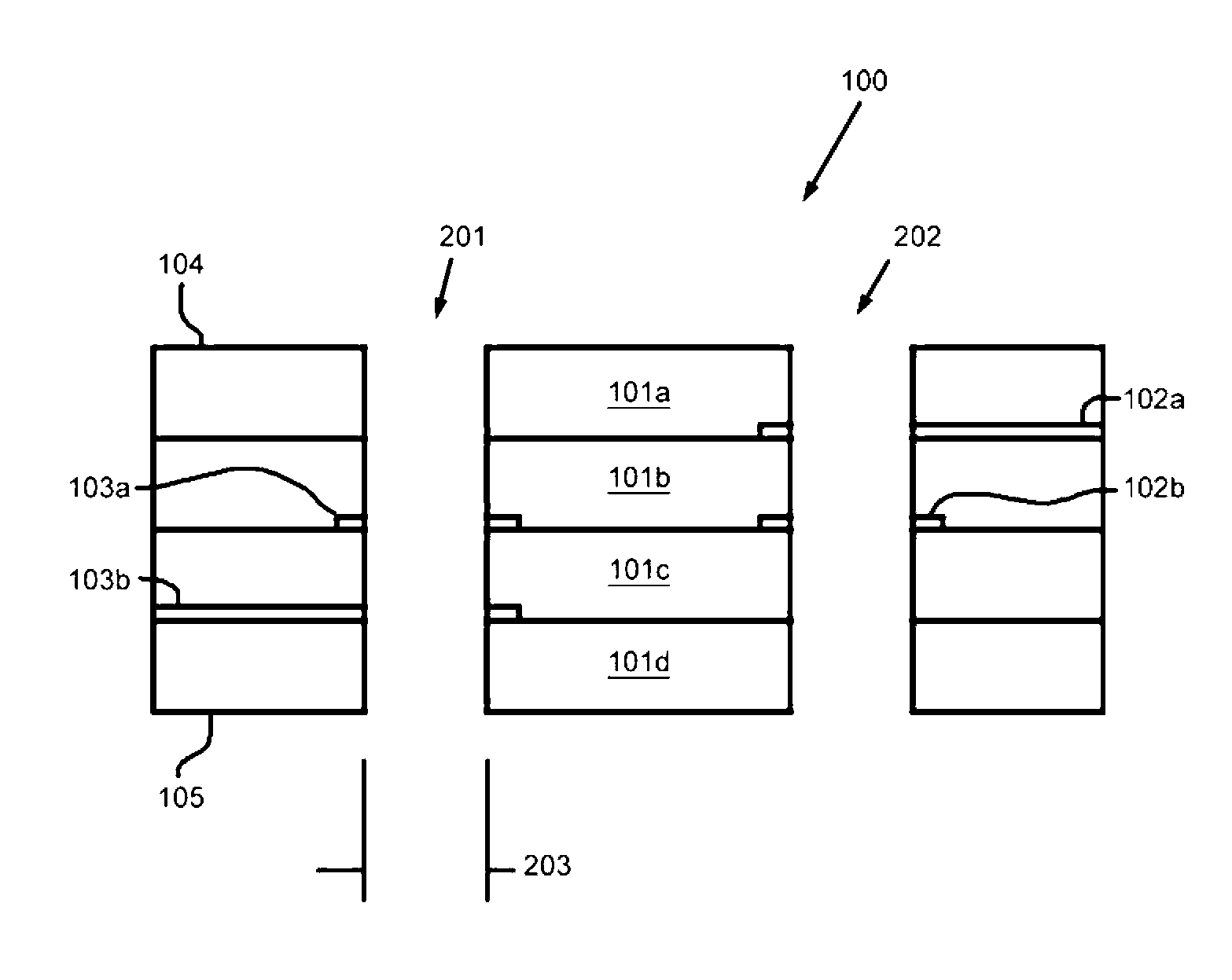

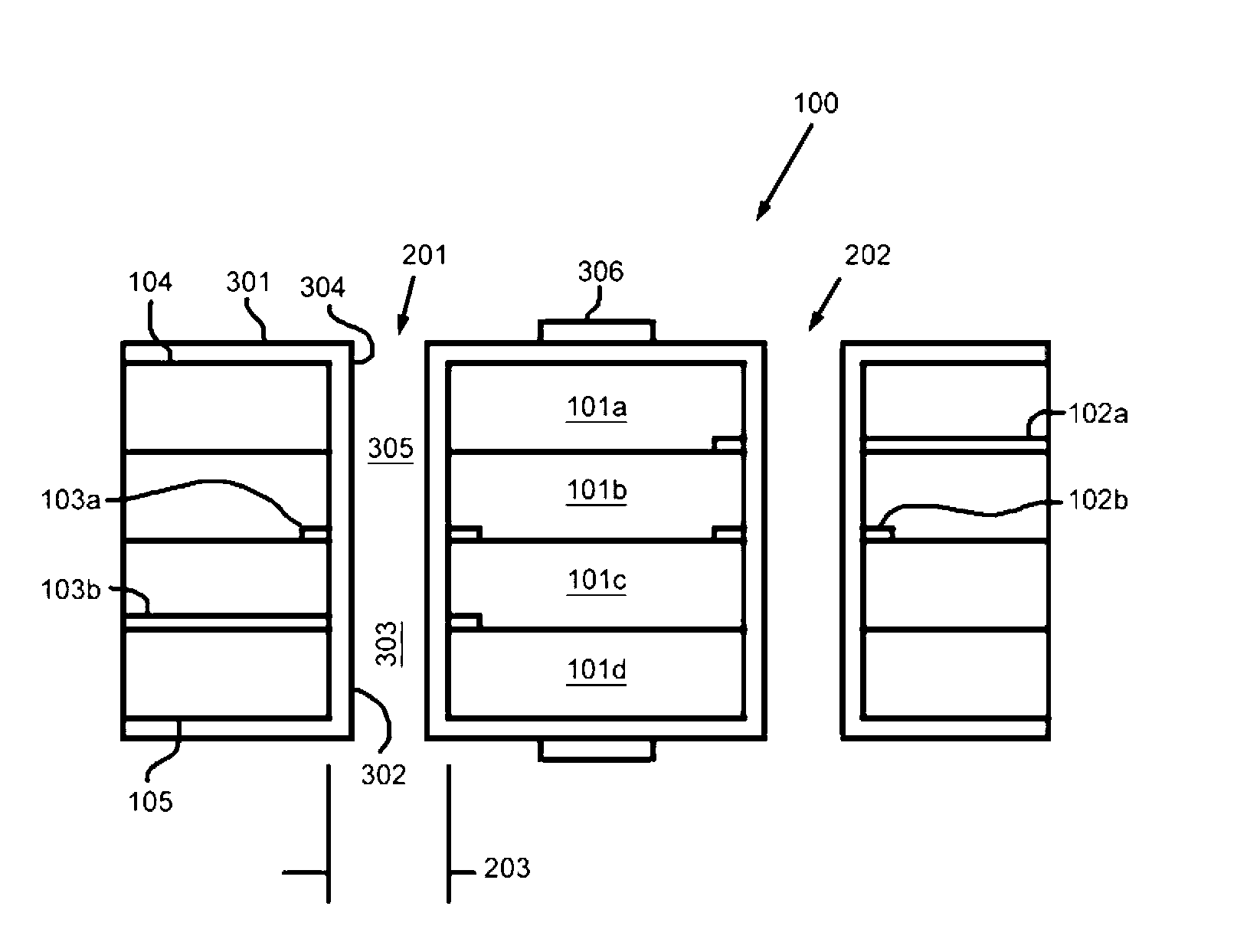

[0021] Embodiments described herein may include PCBs and related manufacturing methods of PCBs in various stages of production. For example, a method of removing via stubs by a combination of backdrilling and chemical etching includes backdrilling the vias to remove the masking layer from the via stubs. After backdrilling is complete, portions of the underlying layer (eg, the conductive layer used to form the conductive path) may remain in the area of the via stub. The remainder of the underlying layer can be removed in a subse...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap