Waterproof and oil-proof magnetic tio2/fe3o4 composite particle and its preparation method and application

A waterproof and oil-proof, composite particle technology, which is used in the preparation of microspheres, magnetic coatings, inorganic material magnetism, etc., can solve the problems of water-proof and oil-proof that are not mentioned, achieve excellent waterproof and oil-proof performance, and is conducive to industrial production and production. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

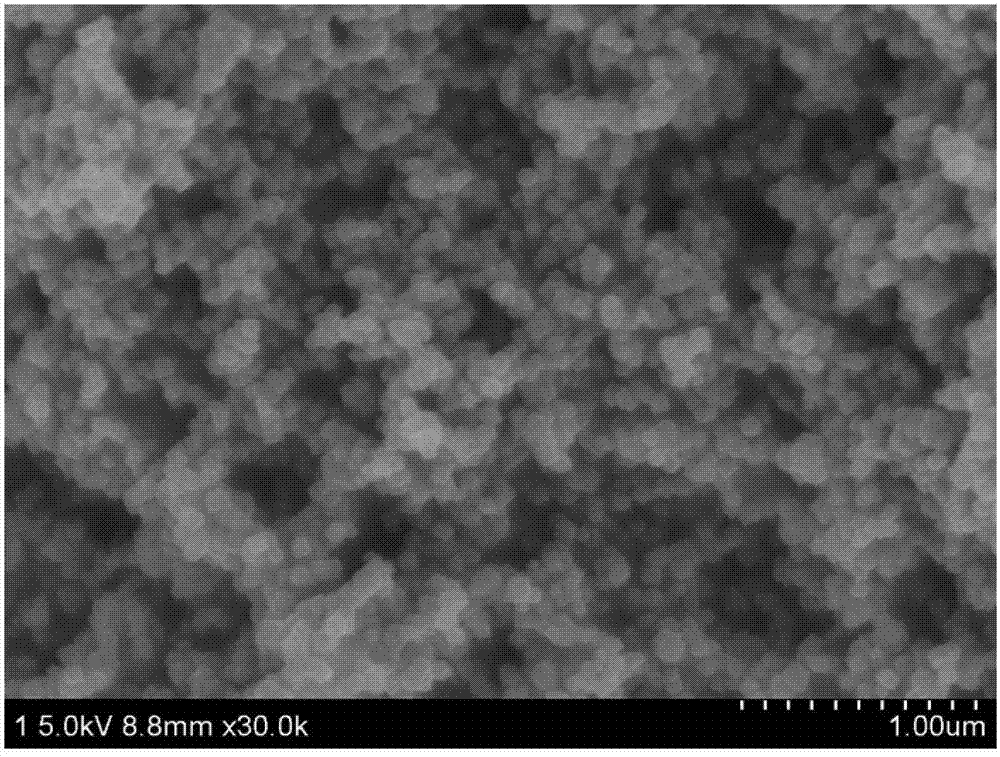

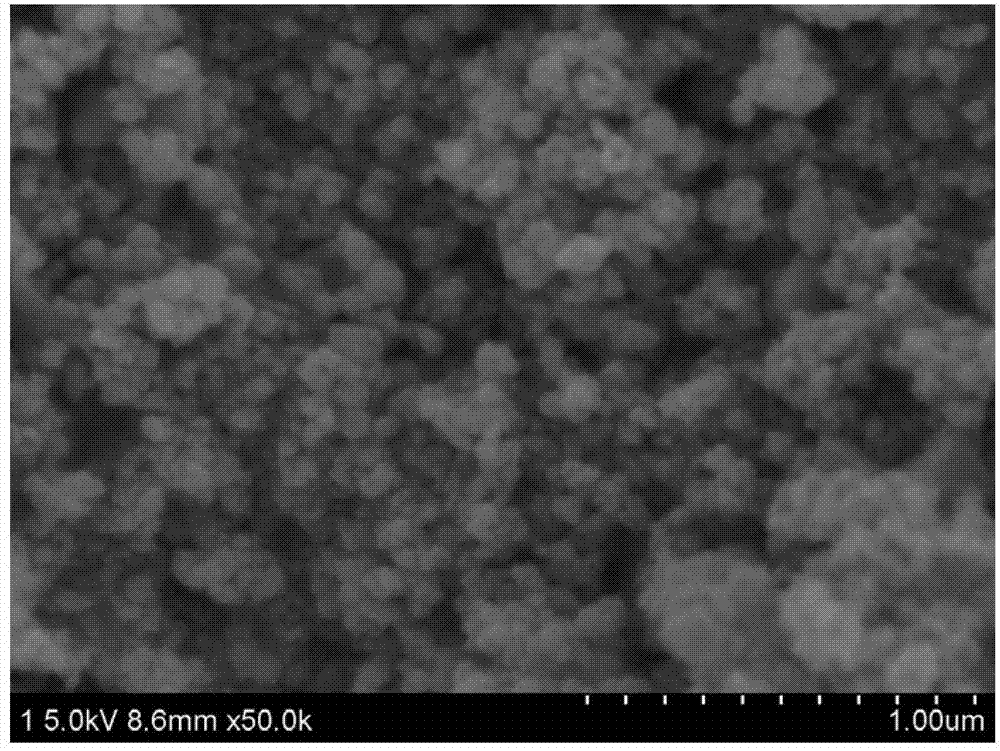

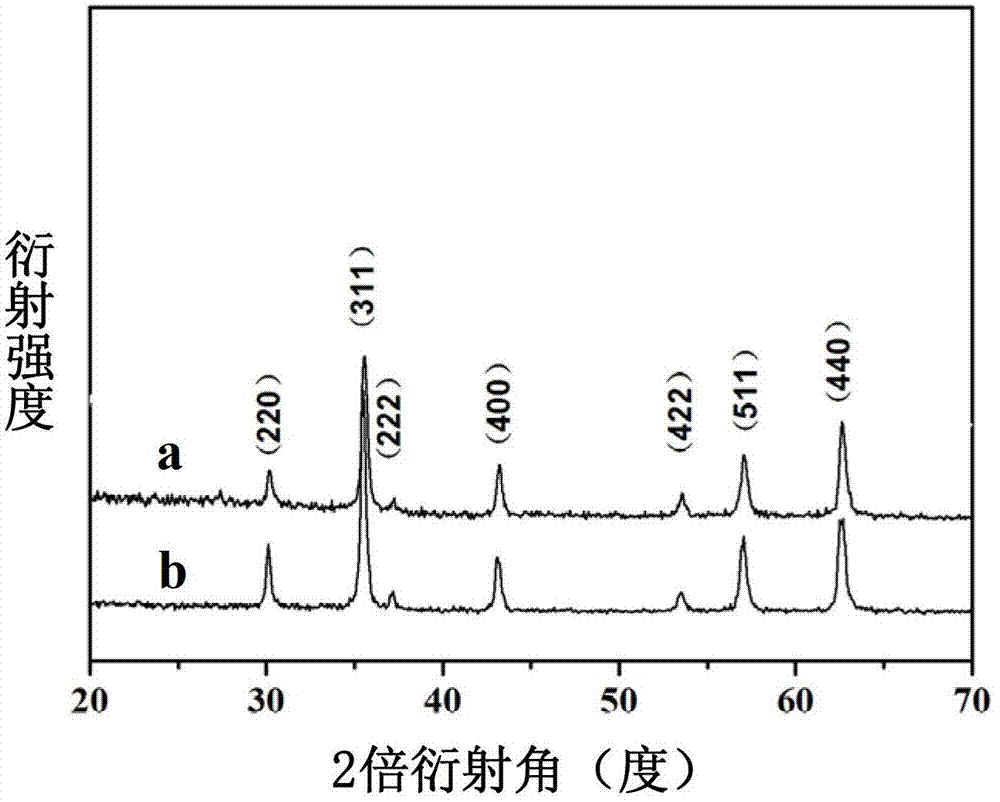

[0042] A kind of waterproof and oil-proof magnetic TiO 2 / Fe 3 o 4 The preparation method of composite particle product, comprises the following steps:

[0043] 1) Fe with different particle sizes 3 o 4 Preparation of particles: prepared by hydrothermal method, 0.65g of FeCl 2 .4H 2 O, 0.5g of Na 2 SO 3 Dissolve 0.2g of polyvinylpyrrolidone (PVP, model K30 polyvinylpyrrolidone produced by BASF, Germany) in 20g of deionized water, then add 0.16g of NaOH, stir evenly, and pass nitrogen gas into it for 30 minutes. , into a 35mL autoclave liner, heated to 140°C for 12 hours, cooled to room temperature 25°C, then taken out of the autoclave liner, and precipitated by magnetic separation (using strong magnetic force to separate the magnetic particles in the reaction solution) The black particles were washed three times with deionized water, then washed three times with ethanol, dried in an oven at 80°C, and stored in vacuum to obtain Fe with different particle sizes. 3 o 4 ...

Embodiment 2

[0059] A kind of waterproof and oil-proof magnetic TiO 2 / Fe 3 o 4 The preparation method of composite particle product, comprises the following steps:

[0060] 1) Fe with different particle sizes 3 o 4 Preparation of particles: prepared by hydrothermal method, 0.65g of FeCl 2 .4H 2 O, 0.58g of Na 2 SO 3 Dissolve 0.25g of polyvinylpyrrolidone (PVP, model K30 polyvinylpyrrolidone produced by BASF, Germany) in 20g of deionized water, then add 0.19g of NaOH, stir evenly, and after blowing in nitrogen gas for 30 minutes, , into a 35mL autoclave liner, heated to 150°C to react for 11 hours, cooled to room temperature 25°C, then taken out the autoclave liner, and used magnetic separation method (using strong magnetic force to separate the magnetic particles in the reaction solution) to precipitate The black particles were washed three times with deionized water, then washed three times with ethanol, dried in an oven at 80°C, and stored in vacuum to obtain Fe with different p...

Embodiment 3

[0064] A kind of waterproof and oil-proof magnetic TiO 2 / Fe 3 o 4 The preparation method of composite particle product, comprises the following steps:

[0065] 1) Fe with different particle sizes 3 o 4 Preparation of particles: prepared by hydrothermal method, 0.65g of FeCl 2 .4H 2 O, 0.4g of Na 2 SO 3 Dissolve 0.14g of polyvinylpyrrolidone (PVP, model K30 polyvinylpyrrolidone produced by BASF, Germany) in 20g of deionized water, then add 0.13g of NaOH, stir evenly, and after blowing in nitrogen gas for 30 minutes, , transferred to a 35mL autoclave liner, heated to 130°C for 13 hours, cooled to room temperature 25°C, took out the autoclave liner, and used magnetic separation (use strong magnetic force to separate the magnetic particles in the reaction solution) to precipitate The black particles were washed three times with deionized water, then washed three times with ethanol, dried in an oven at 80°C, and stored in vacuum to obtain Fe with different particle sizes. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com