Manufacturing method of side wall of vehicle body of metro vehicle

A manufacturing method and side wall technology, which are applied to railway car bodies, railway car body parts, transportation and packaging, etc., can solve the problems of low assembly efficiency, high cost side walls, and poor side wall profiles, and improve assembly efficiency. , The effect of ensuring the profile of the side wall and reducing the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

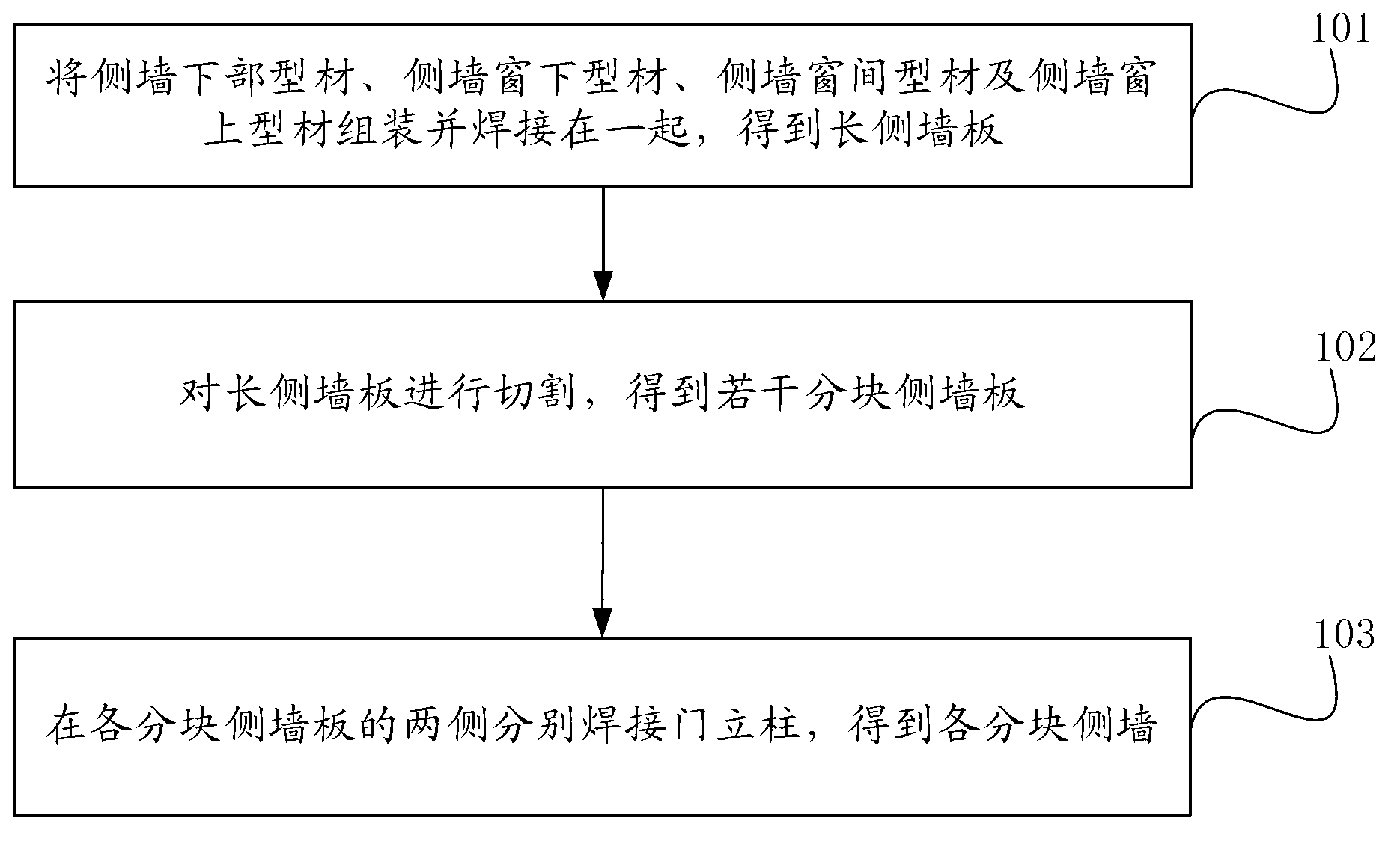

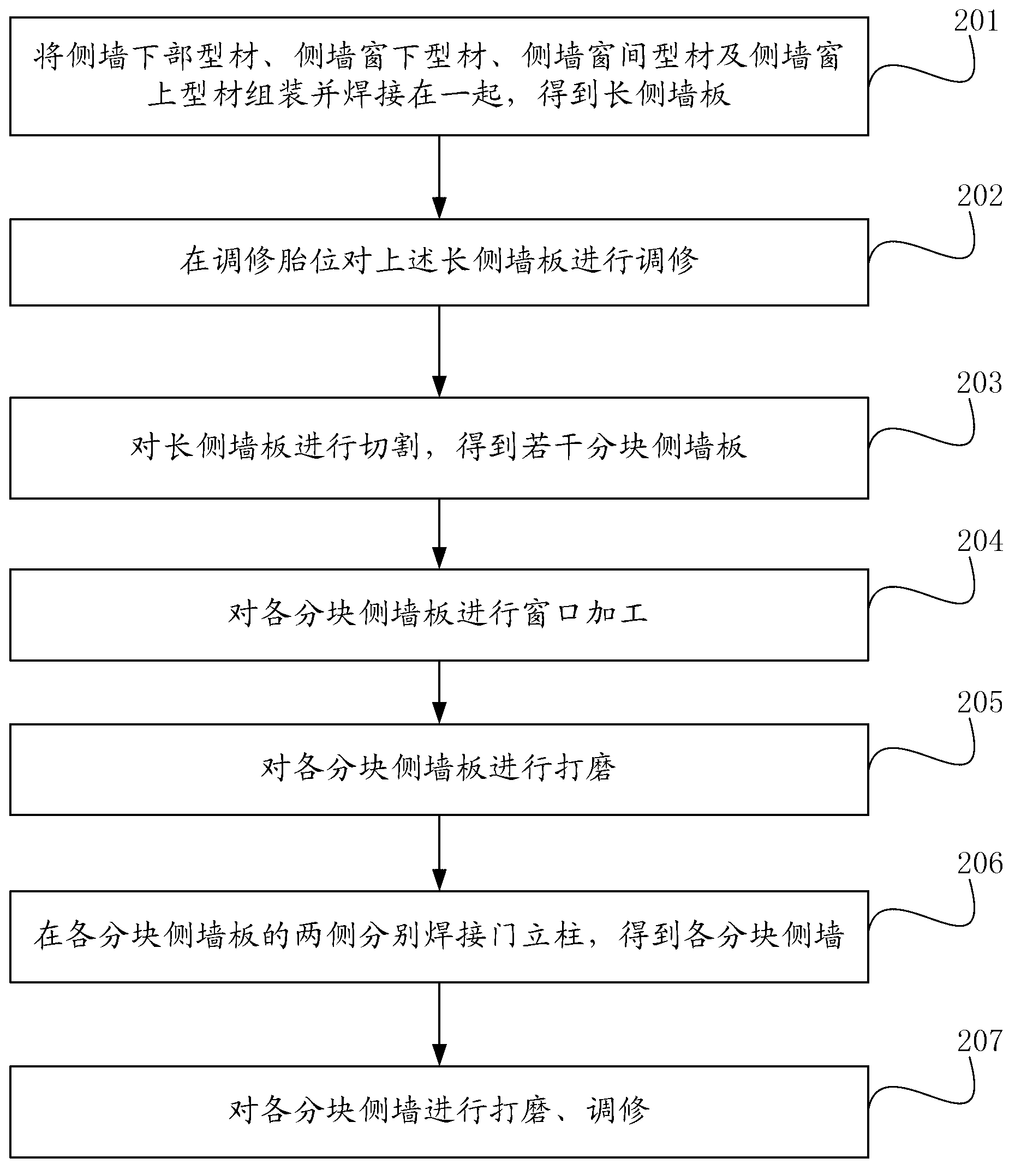

[0017] figure 1 It is a flowchart of a method for manufacturing a side wall of a subway vehicle body provided by Embodiment 1 of the present invention. like figure 1 As shown, the method for manufacturing the side wall of the subway car body provided in this embodiment may specifically include the following steps:

[0018] Step 101, assembling and welding together the lower part of the side wall profile, the lower profile of the side wall window, the profile between the side wall window and the upper profile of the side wall window to obtain a long side wall panel;

[0019] Step 102, cutting the long side wall panels to obtain several side wall panels;

[0020] Step 103 , welding the door columns on both sides of the side wall panels of each block to obtain the side walls of each block.

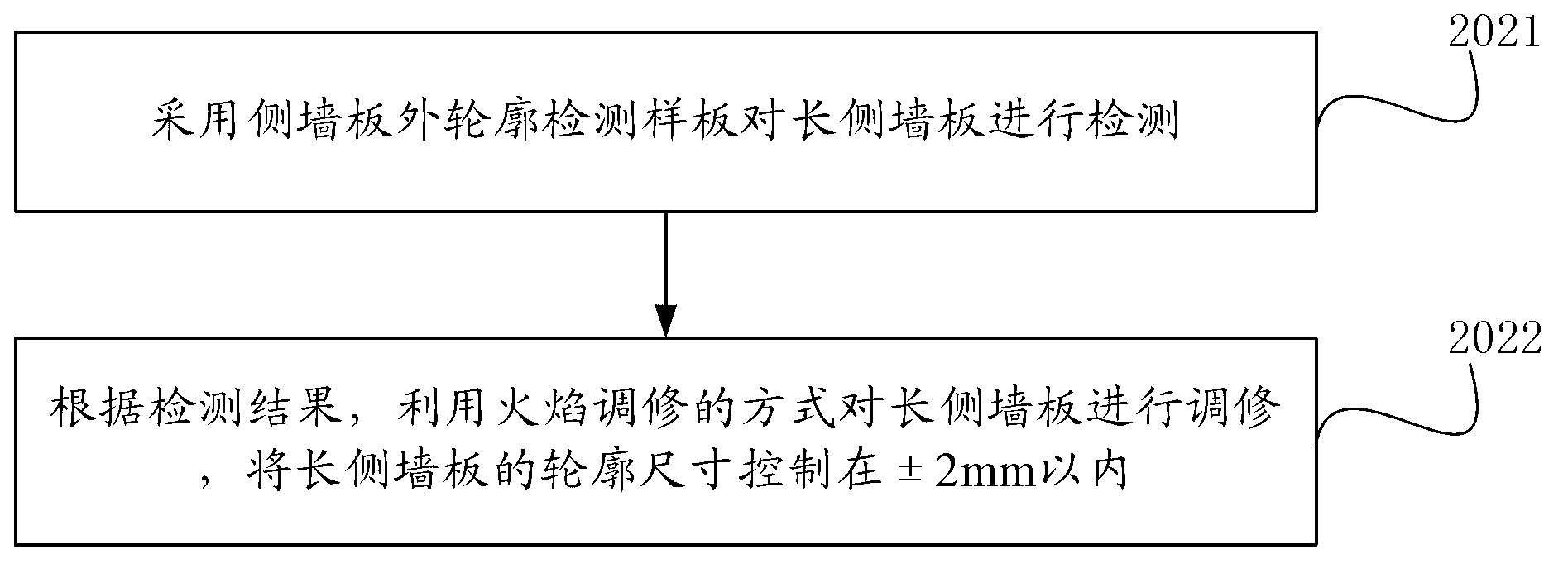

[0021] The specific implementation process of the above step 101 can be as follows: firstly, on the long side wall plate assembly welding tool, assemble the lower part of the side wall pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com