Medium temperature sintering glass powder and preparation method thereof

A technology for sintering glass and medium temperature is applied in the field of medium temperature sintering glass powder and its preparation. Low point, good ohmic contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

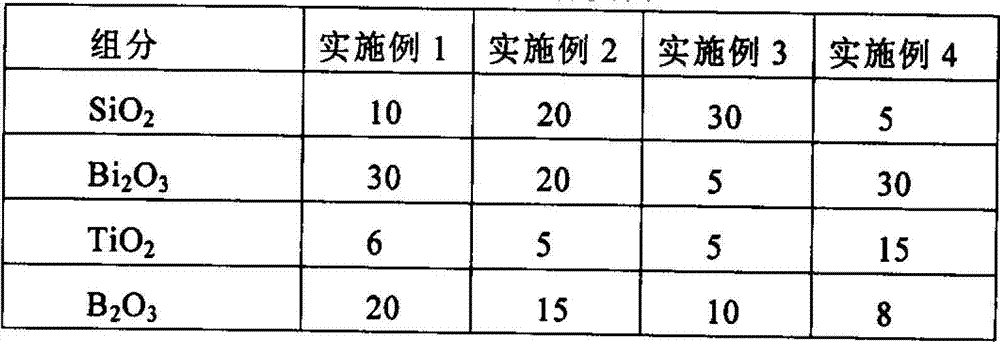

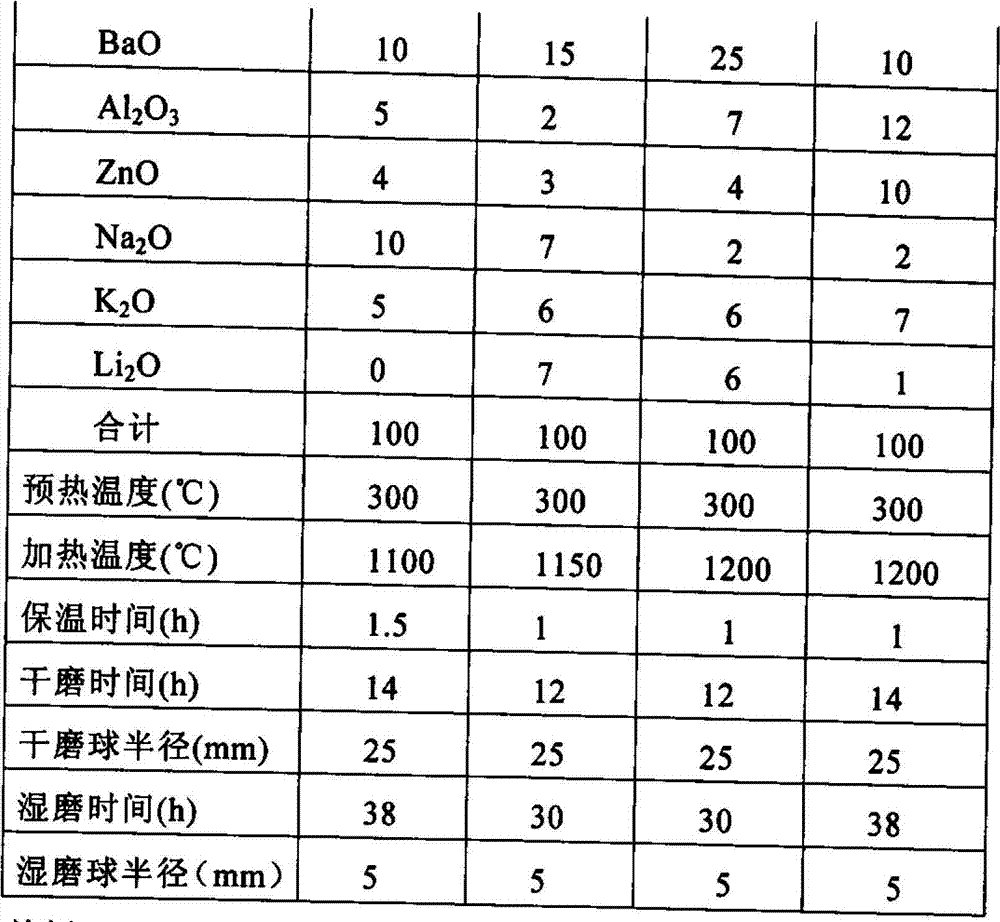

[0025] Provide each raw material according to the composition in Table 1 and mix them evenly. Put the mixture into a muffle furnace at 300°C for half an hour, then transfer it to a high-temperature resistance furnace at 1100°C and heat it for 1.5 hours to obtain clear and uniform glass melting body. Then the glass melt was quenched in deionized water, and after cooling, the quenched glass was dried in a blast oven at 85°C. After drying, use Large grinding balls, 285 rpm, dry grinding for 14 hours. then replace it with The small grinding ball, add alcohol, 350 rpm, wet grinding for 38 hours. After being ground, the glass powder is filtered and dried through a 300-mesh steel mesh to obtain medium-temperature sintered glass powder. Take glass powder to make slurry, and get good ohmic contact performance, such as used in SrTiO 3 When the ohmic paste of the varistor is used, the ohmic contact resistance value after sintering is 0.22MΩ, which meets the market requirements.

Embodiment 2

[0027] Provide each raw material according to the composition in Table 1 and mix them evenly. Put the mixture into a muffle furnace at 300°C for half an hour to preheat, and then transfer it to a high-temperature resistance furnace at 1150°C for heating for 1 hour to obtain clear and uniform glass melting. body. Then the glass melt was quenched in deionized water, and after cooling, the quenched glass was dried in a blast oven at 85°C. After drying, use Large grinding balls, 285 rpm, dry grinding for 12 hours. then replace it with The small grinding ball, add alcohol, 350 rpm, wet grinding for 30 hours. After being ground, the glass powder is filtered and dried through a 300-mesh steel mesh to obtain medium-temperature sintered glass powder. Take glass powder to make slurry, and get good ohmic contact performance, such as used in SrTiO 3 When the ohmic paste of the varistor is used, the ohmic contact resistance value after sintering is 0.2MΩ, which meets the market requ...

Embodiment 3

[0029] Provide the raw materials according to the composition in Table 1 and mix them evenly. Put the mixture into a muffle furnace at 300°C for half an hour and then transfer it to a high-temperature resistance furnace at 1200°C for heating for 1 hour to obtain clear and uniform glass melting. body. Then the glass melt was quenched in deionized water, and after cooling, the quenched glass was dried in a blast oven at 85°C. After drying, use Large grinding balls, 285 rpm, dry grinding for 12 hours. then replace it with The small grinding ball, add alcohol, 350 rpm, wet grinding for 30 hours. After being ground, the glass powder is filtered and dried through a 300-mesh steel mesh to obtain medium-temperature sintered glass powder. Take glass powder to make slurry, and get good ohmic contact performance, such as used in SrTiO 3 When the ohmic paste of the varistor is used, the ohmic contact resistance after sintering is 0.16MΩ, which meets the market requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com