Design method of side wall depth of foundation pit

A design method and foundation pit technology, applied in excavation, infrastructure engineering, construction, etc., can solve problems such as inability to consider the effect of pre-pressure, failure to find a design method, redundant consumption of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

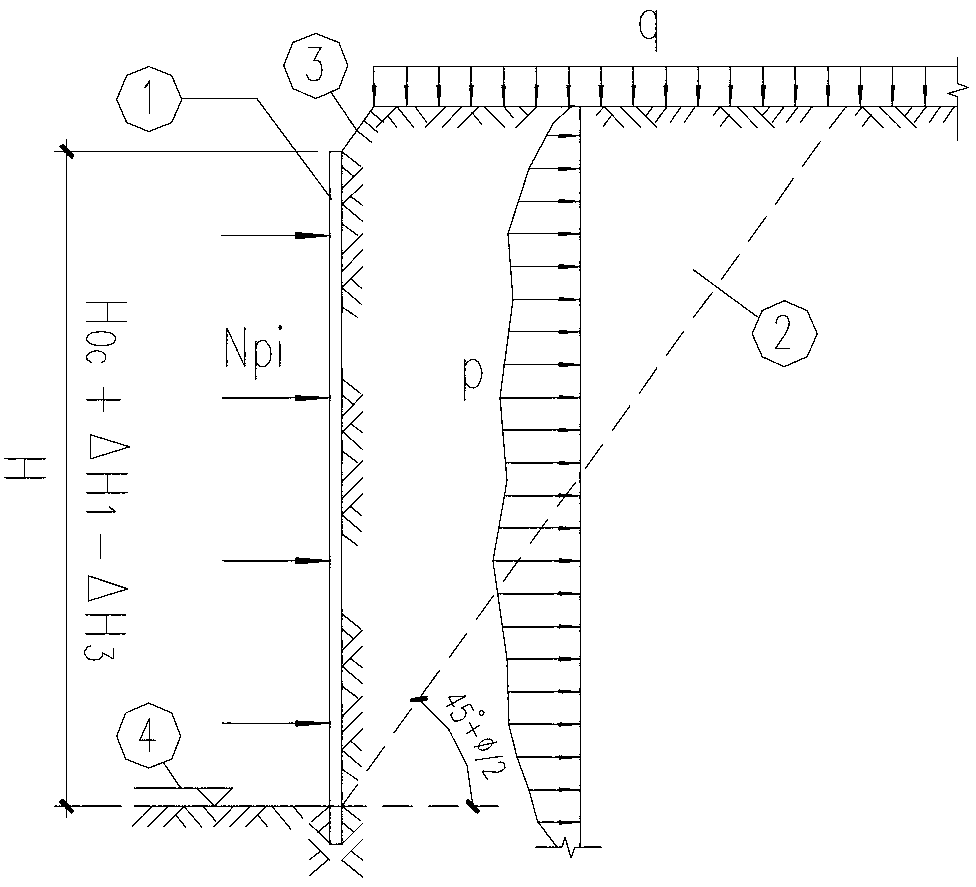

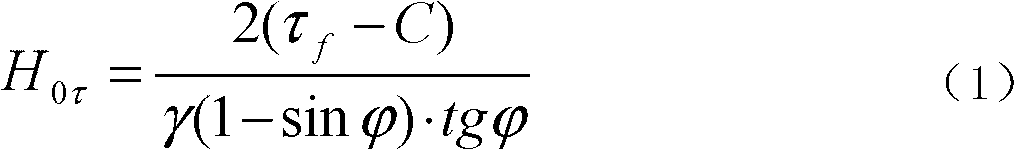

[0033] Specific implementation mode one: as figure 1 As shown, the design method of the depth of the side wall of the foundation pit described in this embodiment is realized according to the following steps:

[0034] Step 1. Calculation formula for the vertical critical depth of the side wall of the foundation pit (the limit depth at which the soil layer can be excavated vertically without enclosure on the side wall of the foundation pit): The natural soil layer τ is given by empirical judgment and experiment f and C value can be calculated by formula (1);

[0035]

[0036] h 0τ : vertical critical depth of side wall of foundation pit;

[0037] τ f : natural shear strength of soil;

[0038] C: cohesion in the soil;

[0039] Soil internal friction angle;

[0040] γ: natural weight of soil layer;

[0041] Note: when the soil layer is cohesive soil, H 0τ =H 0c , with the formula:

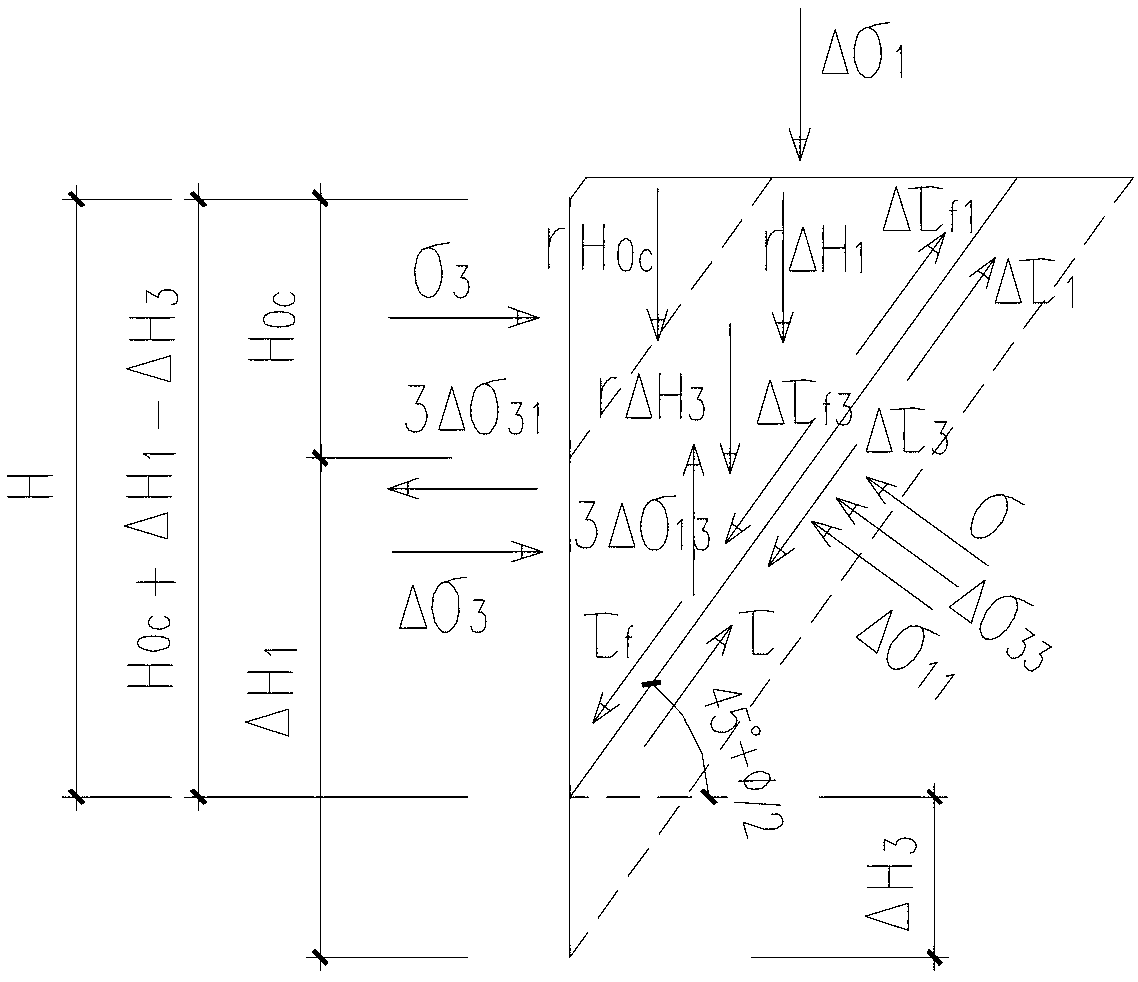

[0042] Step 2, the formula for the stress increment generated in the soil by the ...

specific Embodiment approach 2

[0056] Specific implementation mode 2: In this implementation mode, in step 2, the first parameter "3" on the right side of the equal sign in formulas (2), (3), (4), and (5) can be replaced with one of 1 to 3 other values in between. That is, the first parameter on the right side of the equal sign in formulas (2), (3), (4), and (5) takes a value between 1 and 3, which still belongs to the expression range of the corresponding formula. Other components and connections are the same as those in the first embodiment.

Embodiment

[0058] The design uses prestressed anchor rods to carry beams and double piles, one load and one anchor, and it is easy to apply preload to the piles. figure 1 . Steel-concrete pile diameter: 0.4m, pile distance: 1.2m, horizontal distance between anchor rods 2.4m. The soil layer of the foundation pit is plastic and soft, and the triaxial shear test provides: C = 31.09KPa, , r=19KPa / m. The additional distributed infinite average load on the top of foundation pit q=20KPa( ).

[0059] According to the excavation depth h of the foundation pit on site, it can be obtained from the correlation formula △H1 of formula (6) (mean value), the compressive stress increment in the soil behind the pile P=26KPa (the distribution range length is △H1).

[0060]According to formula (1a): HOc=2×31.09 / 19×tg52.71°=4.30m

[0061] According to formula (3): △H1=3 / 19×tg 2 52.71°×26=7.08m

[0062] According to formula (5): △H3=3 / 19×tg 2 37.29°×20=1.83m

[0063] According to formula (6): H=4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com