Flexible attachment arranging and selecting method of ultra-large type cooling tower construction tower crane based on tower barrel safety

A technology of flexible attachment and cooling towers, which is applied in the selection of flexible attachment layout of tower cranes and the selection of flexible attachment layout of super-large cooling tower construction tower cranes. It can solve the problems of low safety, high cost of tower body, delay in construction period, etc., and achieve enhanced safety. High reliability, low tower cost, and safe tower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

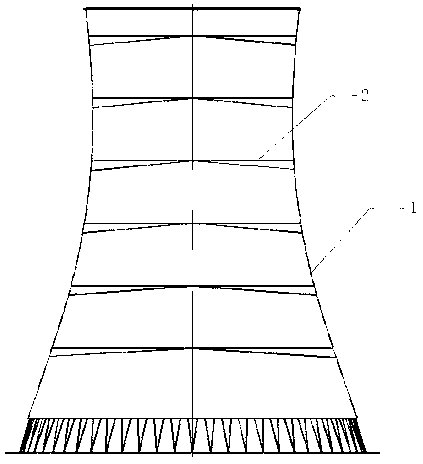

[0039] Figure 1-Figure 8 Constitute the specific embodiment 1 of the present invention.

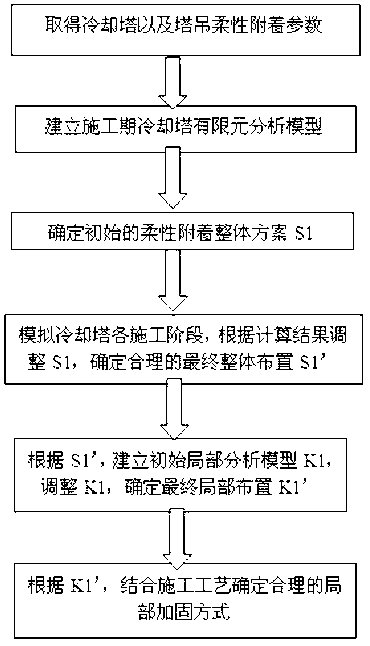

[0040] refer to figure 1 , the steps of the flexible attachment arrangement selection method in this embodiment are as follows:

[0041] 1) Obtain the size of the cooling tower and the flexible attachment parameters of the tower crane

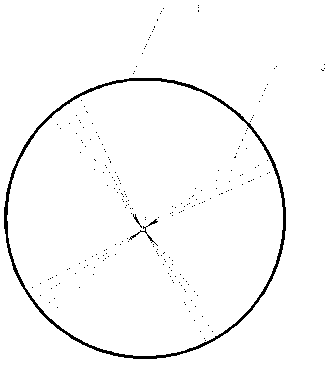

[0042] refer to figure 2 with image 3 , for 22000m 2 The super-large cooling tower tower tube construction adopts the flexible attachment arrangement of single tower crane operation. When vertically arranged, the independent height of the tower crane is 55.1m, and the distance between each vertically attached vertically arranged 2 is 33m; when arranged horizontally, four directions of attached planarly arranged 3 are adopted, and each direction is divided into upper and lower floors. There are 8 attachment points in total, and the horizontal and vertical spacing of each attachment point is 5m. The tension of the flexible attachment of the tower cr...

specific Embodiment

[0062] The main features of this embodiment are: according to the size of the cooling tower and the flexible attachment parameters of the tower crane, 4 or 5 finite element models of cooling towers in different construction stages are established, and solid element modeling is used. All the other are with specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com