Backfilling stand shoring system of three-dimensional prestress wire of deep soft rock roadway

A technology of prestressed steel strands and steel strands, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems such as excessive clearance, uneven stress on supports, biased pressure, etc., to achieve uniform stress and prevent local The effect of cracking failure and short initial setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

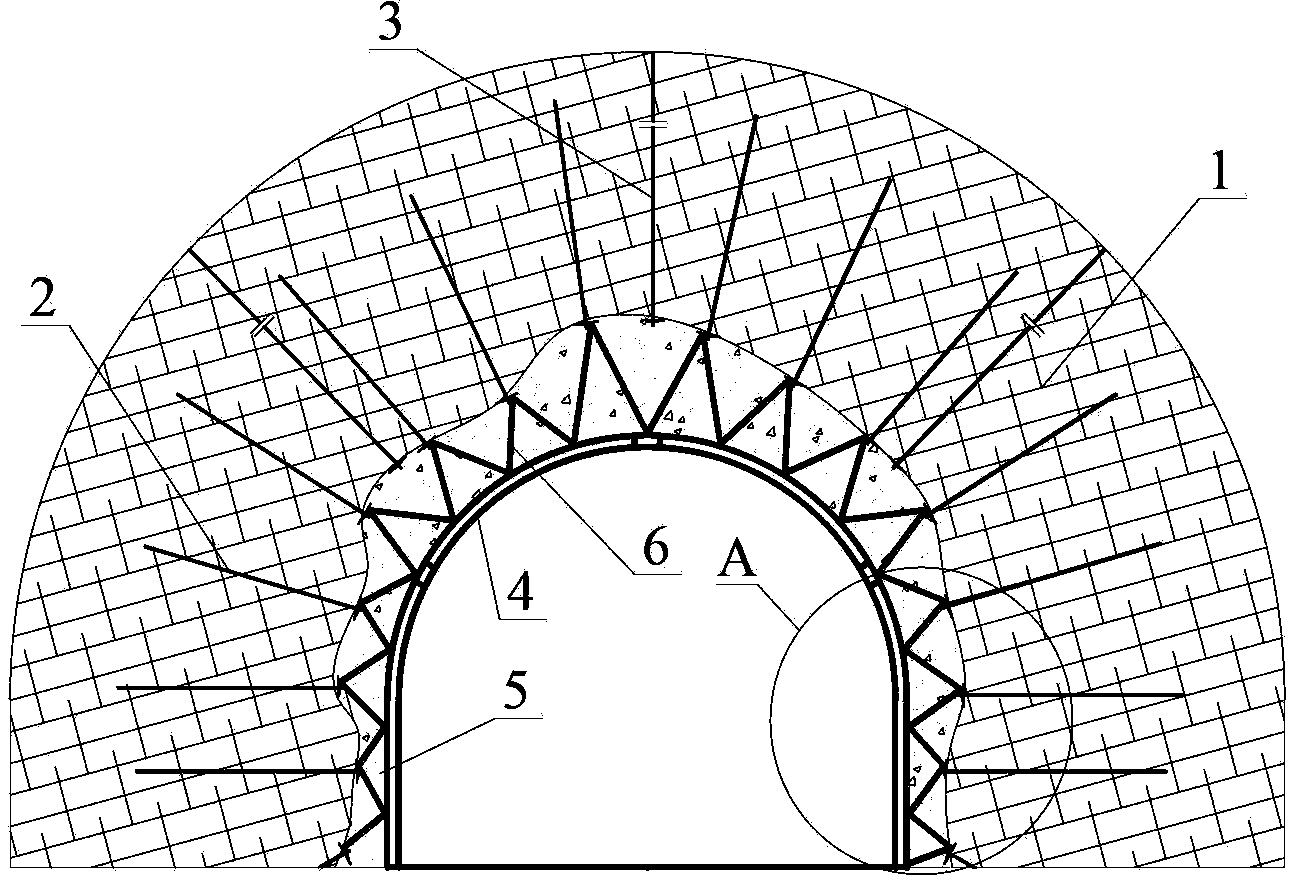

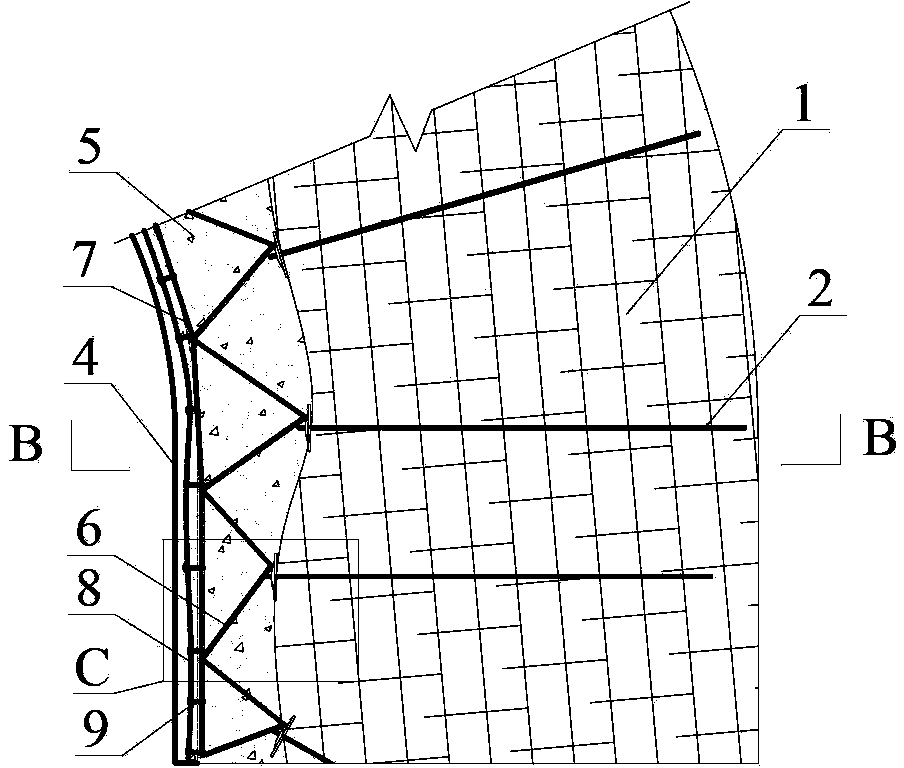

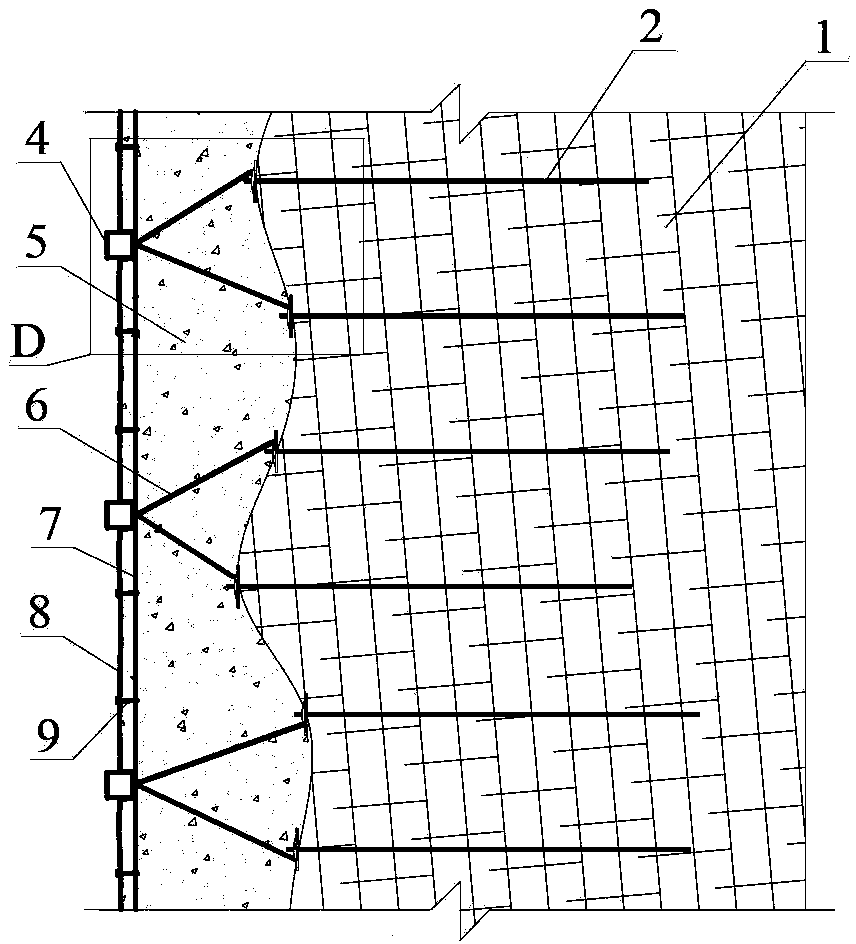

[0044] refer to Figure 1~6 , the specific embodiment of the present invention is, deep soft rock roadway three-dimensional prestressed steel strand wall rear filling support support system (abbreviated as SAFA support system), main support 4, anchor rod 2, anchor cable 3, three-dimensional prestressed steel The strand system (that is, the frame-anchor steel strand 6 and the frame-frame steel strand 7), the filling material 5 behind the support wall and the filling baffle 8 are composed.

[0045] Wherein, the support 4 forms the inner load-bearing structure of the support system, and the anchor rod 2 and the anchor cable 3 form the outer load-bearing structure of the support system. The three-dimensional prestressed steel strand system (frame-anchor steel strand 6 and frame-frame steel strand 7) connects the bracket 4 and the anchor rod 2 and the ancho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com