Clutch of electrombile bearing

A clutch and electric vehicle technology, applied in the field of clutches, can solve the problems of large radial displacement, limited torque, large axial runout, etc., and achieve the effect of simple structure, large noise and small axial runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

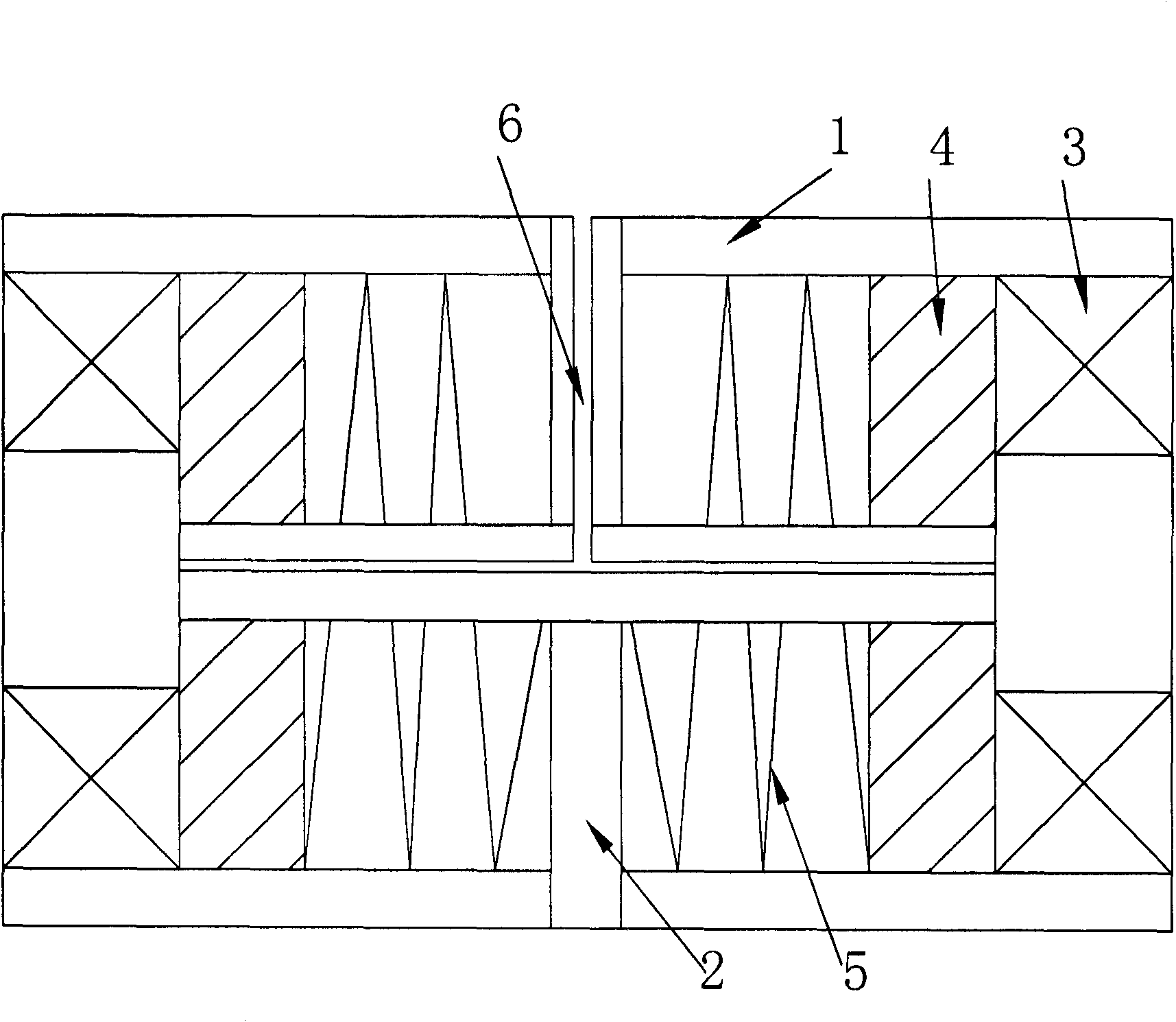

[0010] Such as figure 1 As shown, the electric vehicle bearing clutch includes a cage 1, an isolation plate 2 is arranged in the middle of the cage 1, and a clutch device is arranged on both sides of the isolation plate 2, and each clutch device includes an angular contact bearing 3, a thrust Sleeve 4 and the elastic part, the elastic part is set on the side of the isolation plate, the thrust sleeve is set on the end of the elastic part, the angular contact bearing is set on the other end of the thrust sleeve and connected with the thrust sleeve through an angular groove, and the end surface of the angular contact bearing is provided with an angular contact bearing. groove. The end face of the thrust sleeve is provided with a corner block matched with the angle groove, the corner block is arranged in the angle groove, and a connecting shaft connects the two thrust sleeves.

[0011] The elastic component is the spring 5 .

[0012] Lubricating oil holes 6 are provided on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com