Ammunition link small-diameter artillery ammunition feeding and recoil and counter-recoil analog device

A simulation device and small-caliber technology, which is applied in the field of recoil function device, ammunition supply and recoil, can solve the problems of not being able to clearly and effectively observe the working conditions of the ammunition supply system, time, human and material resources, and large financial resources, so as to shorten the The effect of development cycle, saving test funds and saving research and development funds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

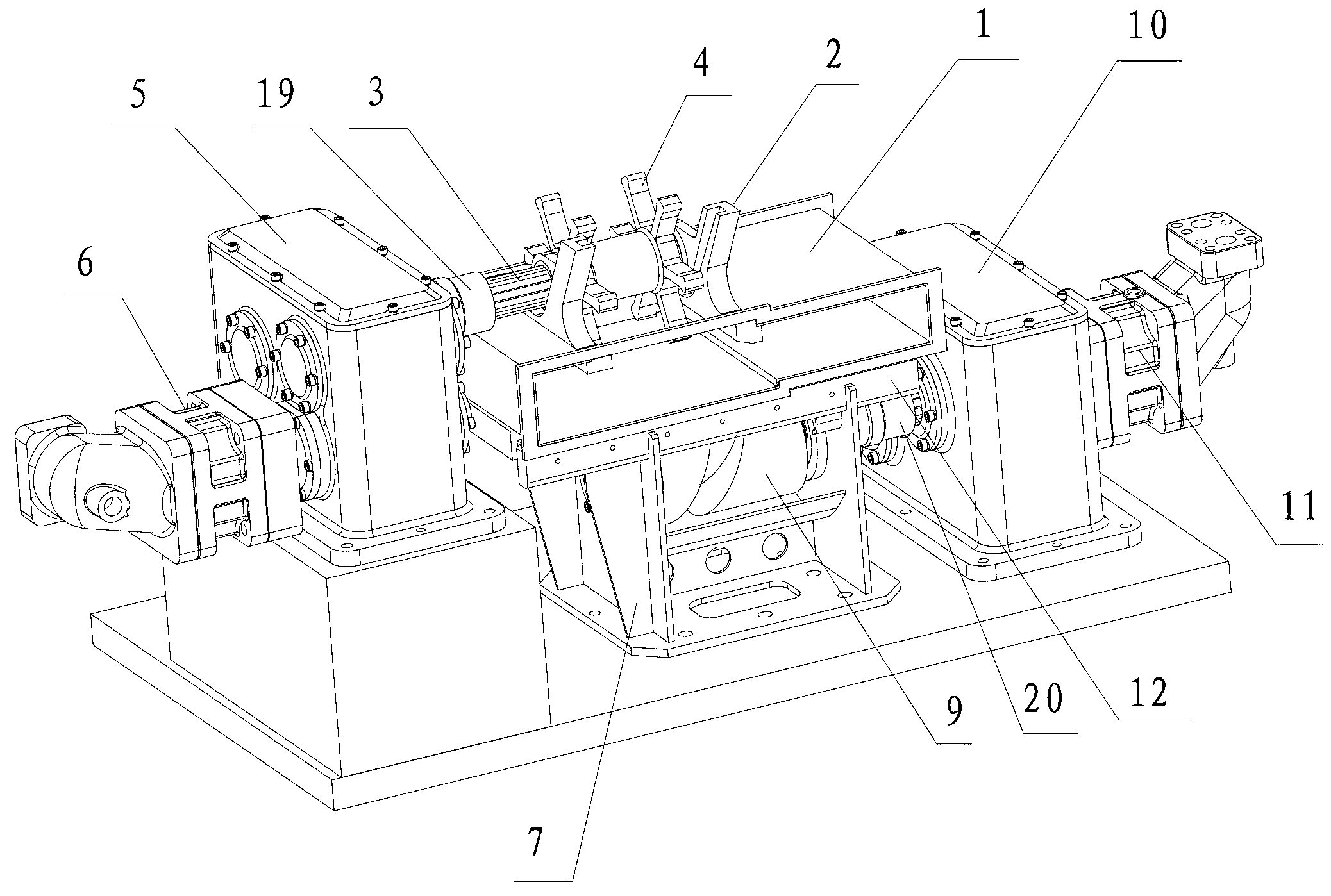

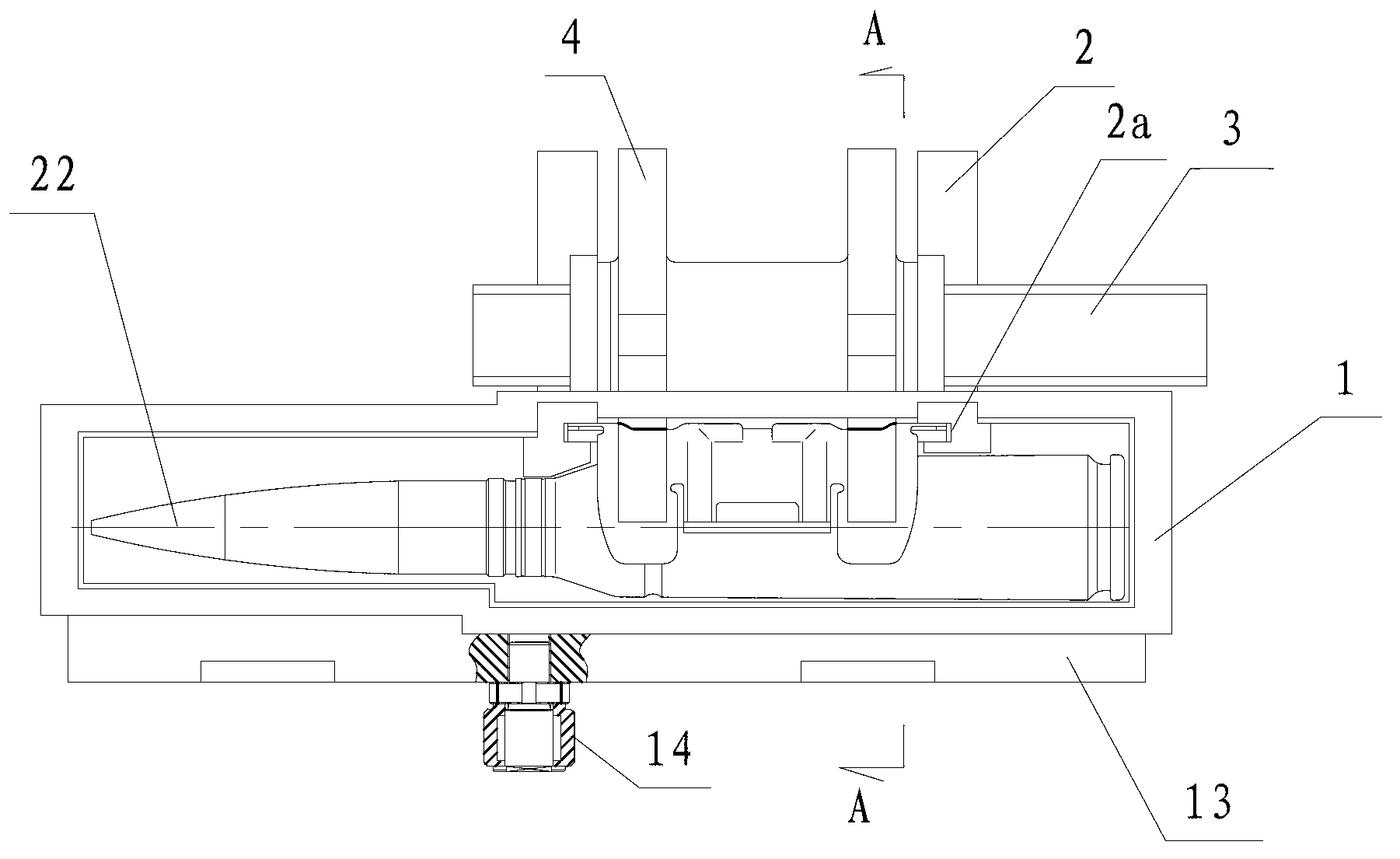

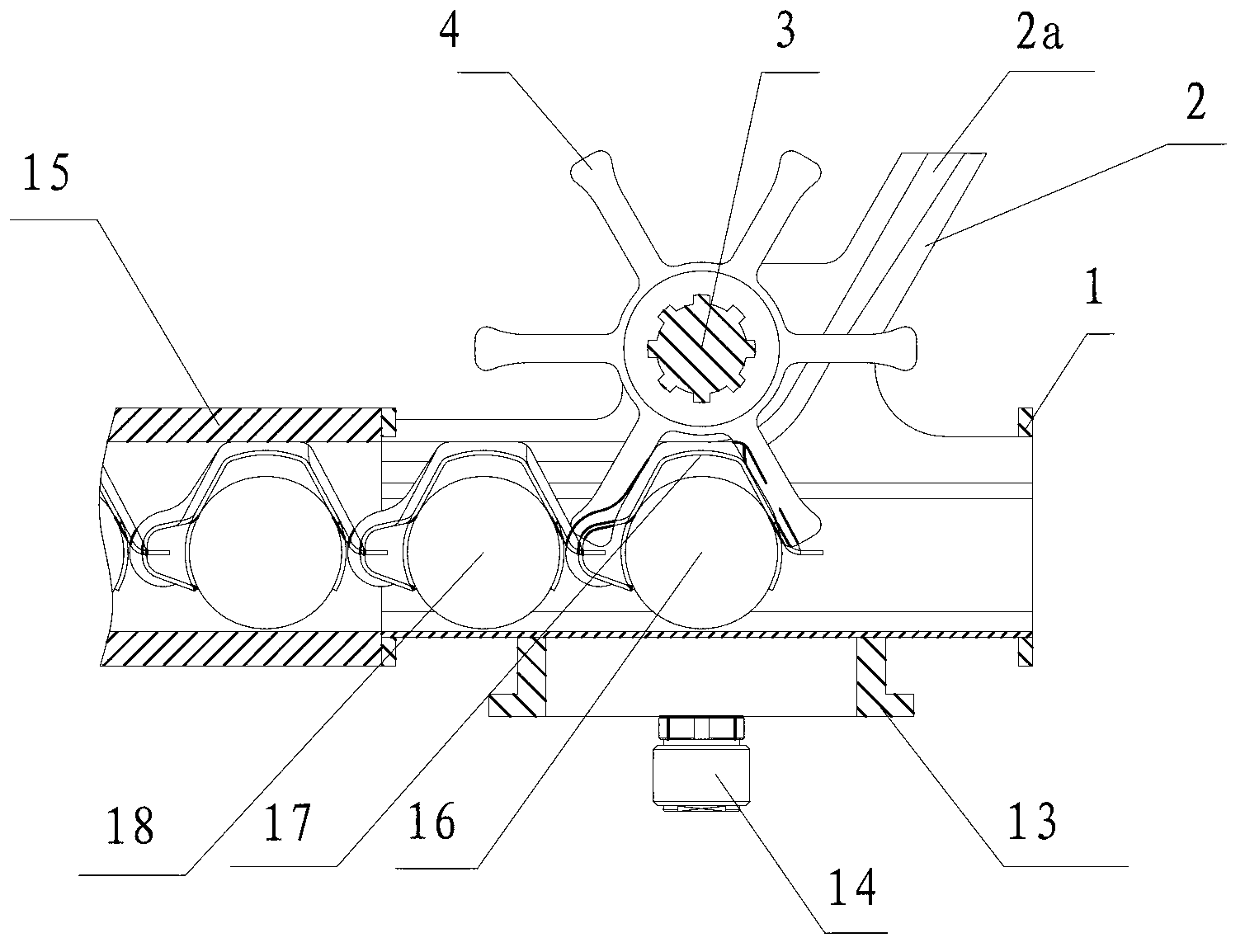

[0017] see Figure 1~3 , the device consists of a bomb feeding simulation mechanism and a recoil recoil simulation mechanism located below the bomb feeding simulation mechanism; the bomb feeding simulation mechanism has a bomb feeding guide (1), and the bomb feeding guide ( 1) It is a rectangular cavity. The longitudinal axis of the rectangular cavity is parallel to the bomb axis (22), and its left and right sides are open. The left cavity is used as the shell entrance and the right cavity is used as the shell discharge. The upper end surface of the bullet guide is embedded with a pair of bullet chain racks (2) which are axially oppositely arranged forward and backward, and the bullet chain racks (2) are provided with bullet chain guide grooves (2a) (see image 3 ), a spline shaft (3) is arranged along the direction of the long axis of the bomb supply guide, and is installed on the chain frame (2) through a shaft sleeve, so as to realize the rotary support of the chain frame t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com