Volume correcting instrument indication error calibration standard device and using method

A technology of volume correction and indication error, applied in testing/calibration devices, measuring devices, instruments, etc., can solve problems such as large uncertainty of calibration results, lack of calibration standards, and difficulty in disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

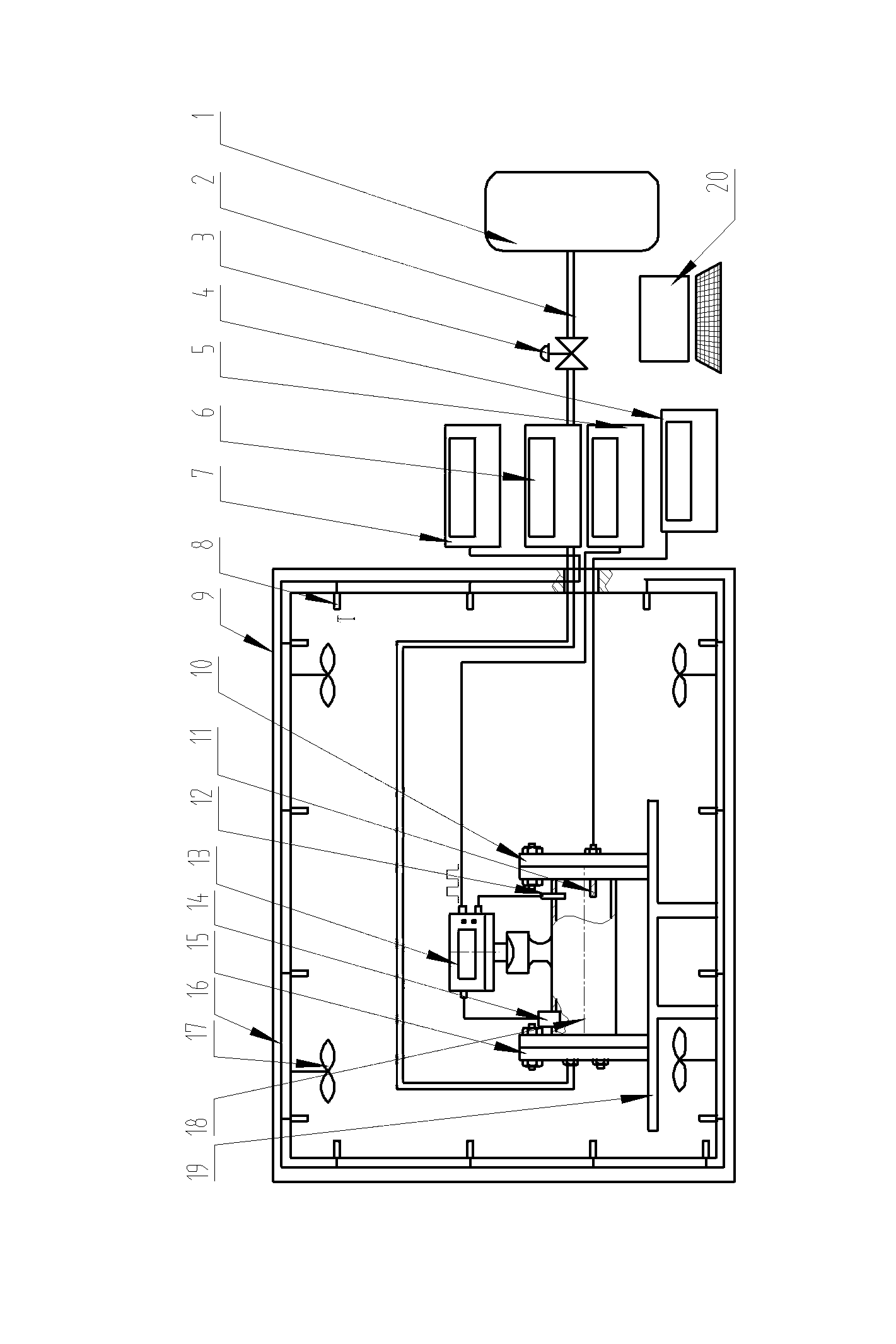

[0023] Such as figure 1As shown, the temperature sensor 12 of the volume correction instrument, the pressure sensor 14 of the volume correction instrument, the volume correction instrument 13 and the flow base meter 18 are connected to each other to form an integral intelligent flow meter and a computer 20, which is characterized in that: the volume correction instrument Indication error calibration standard device is provided with a constant temperature box 9, the temperature sensor 8 of several constant temperature boxes and several fans 17 are installed on the casing inner wall of described constant temperature box 9, and the casing bottom surface of described constant temperature box 9 is provided with There is a bracket 19, on which a blind plate 10 with a temperature test hole and a blind plate 15 with a pressure test hole are arranged, and a gas pipeline 2 is connected to the pressure test hole of the blind plate 15 with a pressure test hole , the gas pipeline 2 is seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com