Apparatus and method for detecting internal and external crack defects of metal material

A metal material and crack technology, which is applied in the field of detection of internal and external crack defects of metal materials, can solve problems such as inability to obtain complete defect information, and achieve the effect of improving defect evaluation and complete detection information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

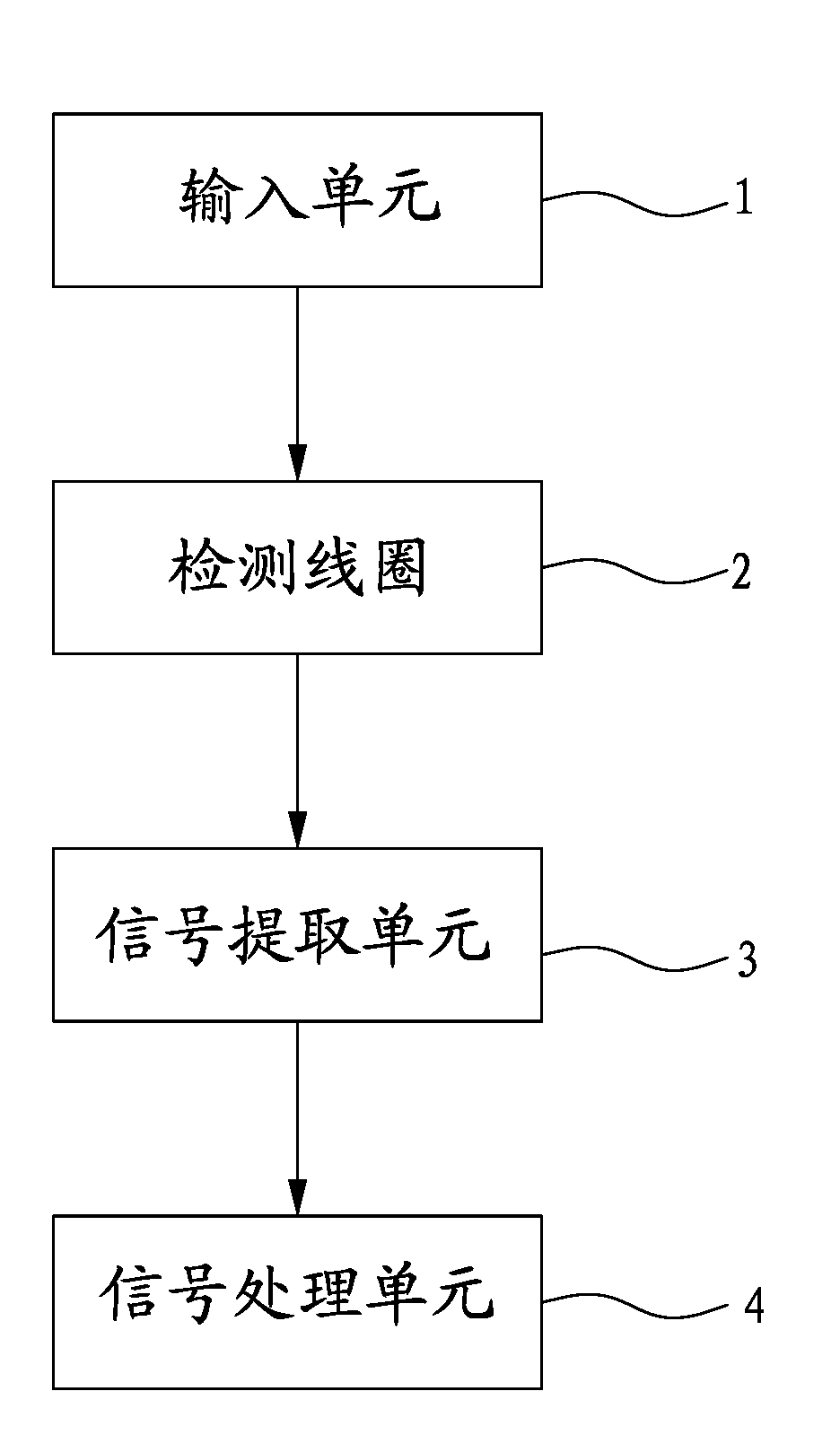

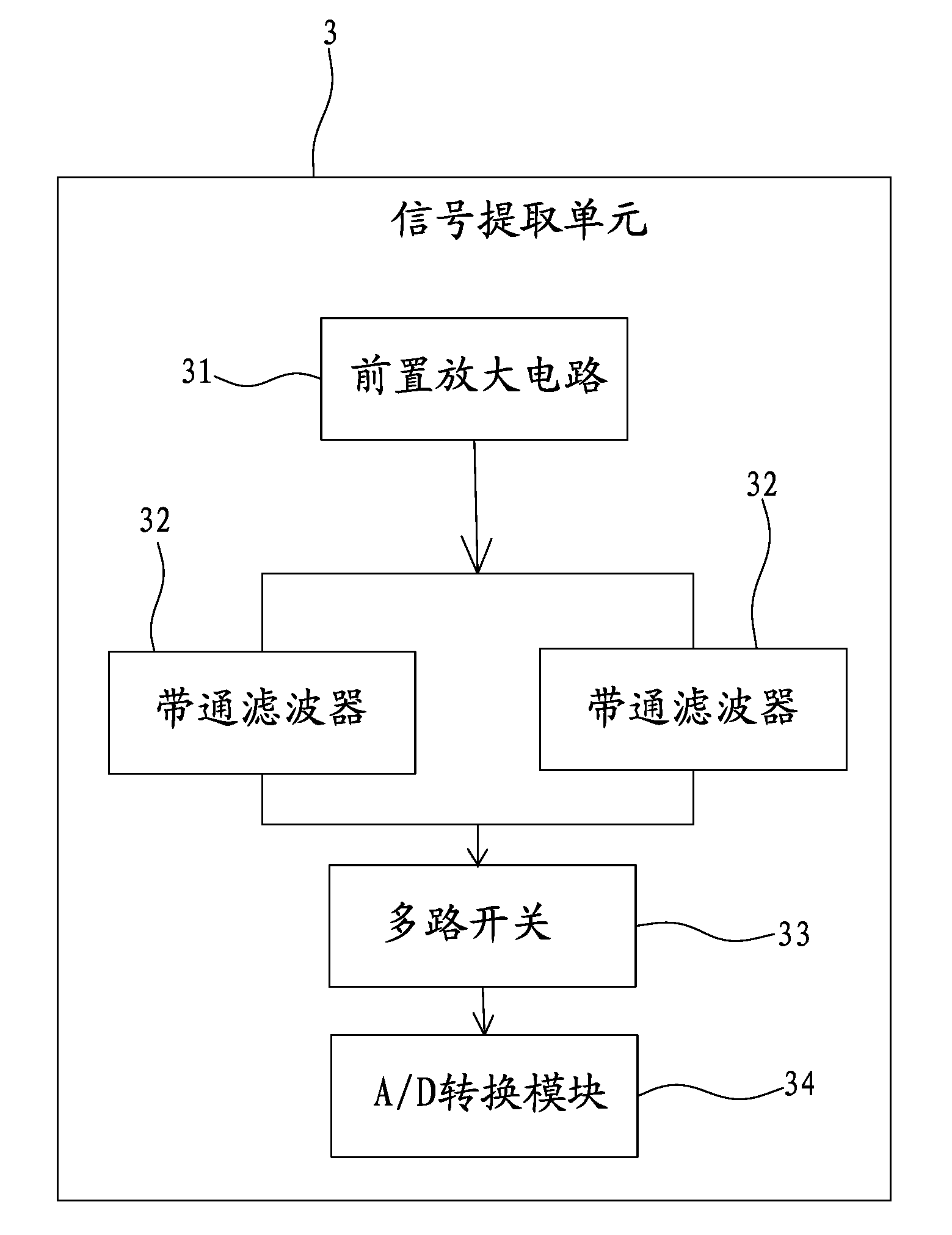

[0032] like Figure 1 to Figure 3 As shown, it is a device for detecting internal and external crack defects of metal materials involved in the present invention, including an input unit 1, a detection coil 2, a signal extraction unit 3 and a signal processing unit 4, wherein:

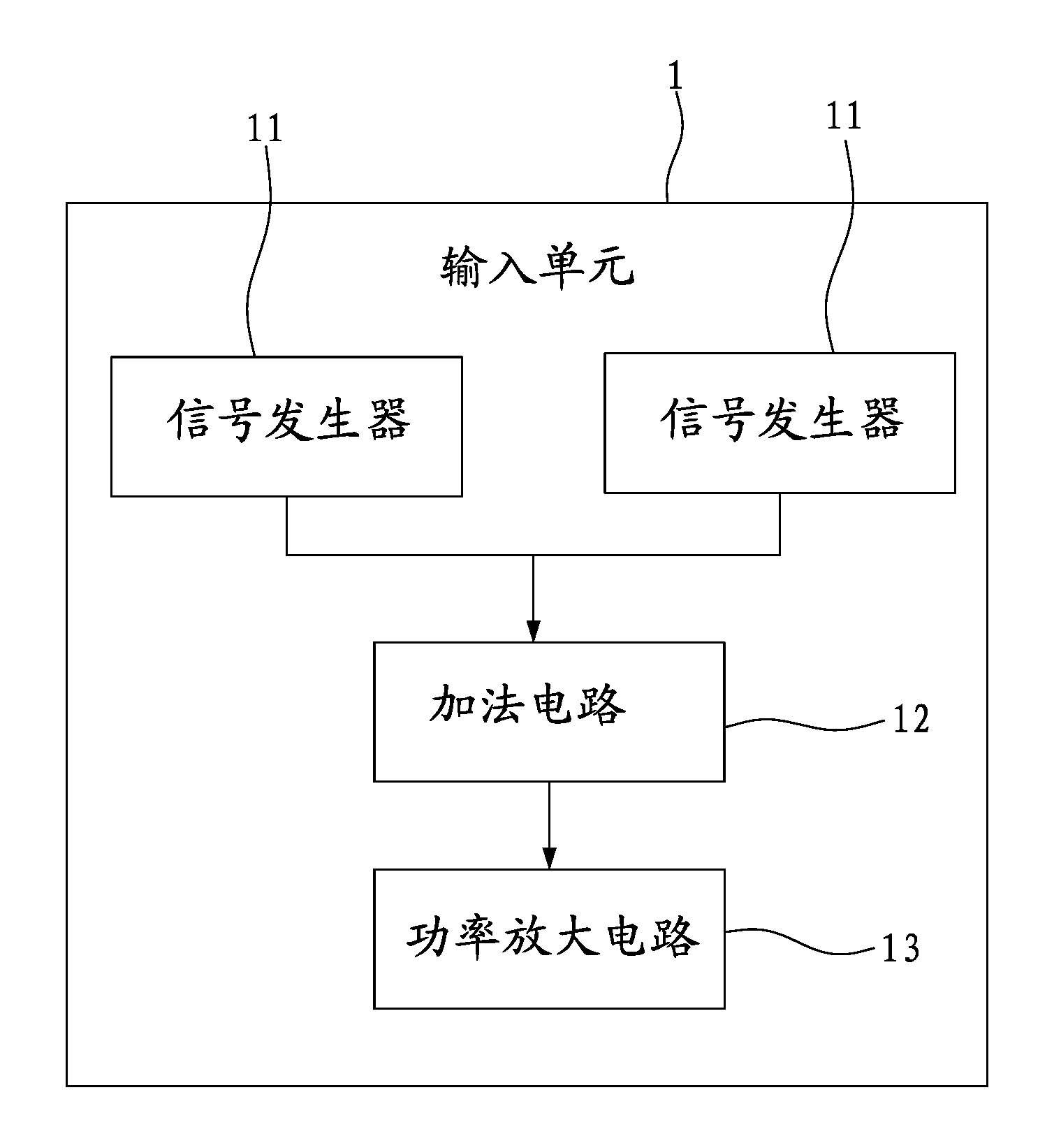

[0033] The input unit 1 has at least two signal generators 11, an adding circuit 12 and a power amplifier circuit 13, the signal generators 11 are used to generate excitation signals, and different signal generators 11 are used to generate excitation signals of different frequencies; The addition circuit 12 is connected to at least two signal generators 11, so that the excitation signals of different frequencies are superimposed to generate a composite excitation signal; the power amplifier circuit 13 is connected to the addition circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com