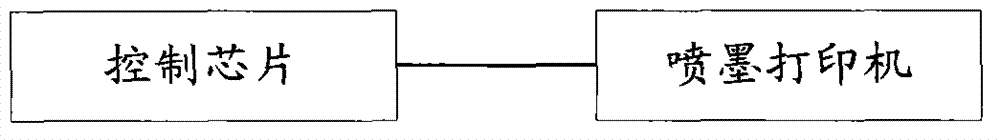

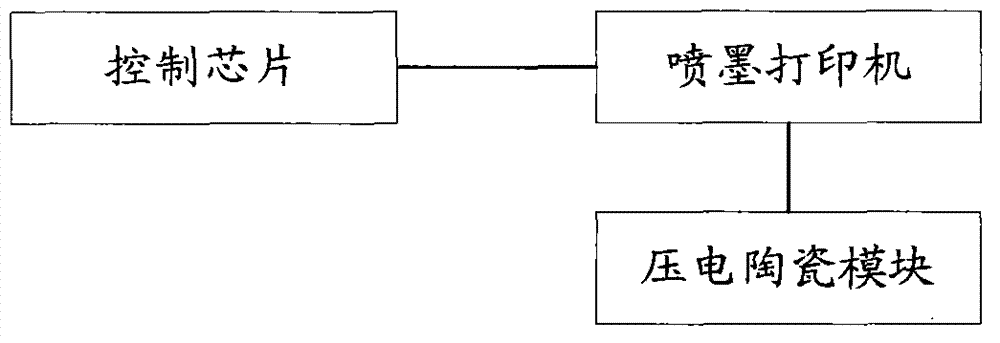

Excitation response simulation circuit applied to printer

An excitation-response, analog circuit technology, applied in printing, electrical components, power oscillators, etc., can solve the problems of poor compatibility of excitation-response analog circuits, easy ink leakage, and high manufacturing costs, and improve the characteristics of positive and negative polarity circuits. , improve the DC characteristics, and facilitate the effect of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

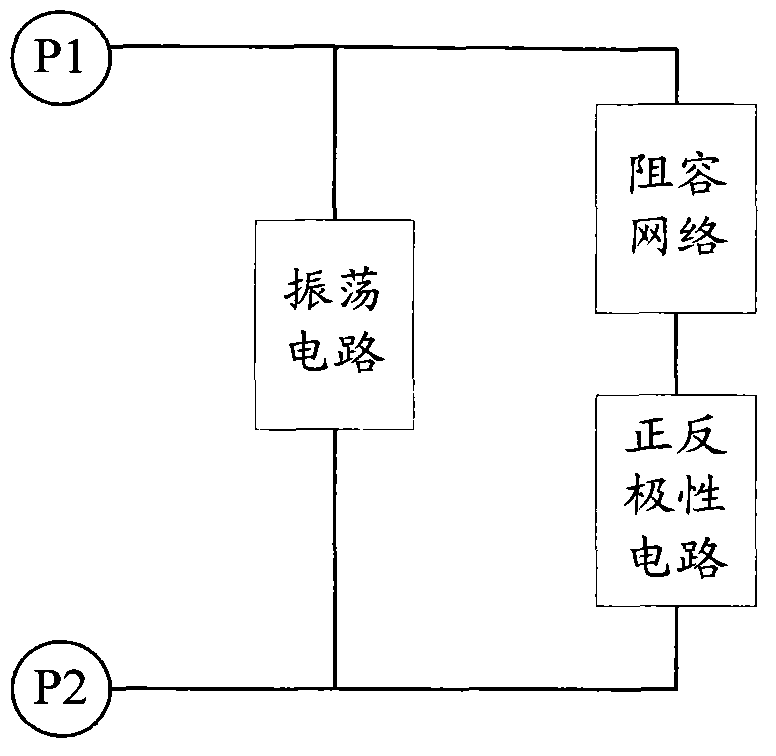

[0057] Figure 7 A schematic diagram of an excitation response analog circuit applied to a printer provided by the present invention, the positive and negative polarity circuits in this structure are implemented by an insulated gate field effect transistor and a resistance-capacitance adjustment module. Specifically, and prior art Figure 5 Compared with the stimulus-response analog circuit in the above, the forward and reverse polarity circuit adopts N-type insulated gate field effect transistor Q2 to connect resistor R1 and capacitor C1 in series to realize, wherein, the gate of N-type insulated gate field effect transistor Q2 The pole is connected to an excited end of the circuit, the source is connected in series with the resistor R1, the drain is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com