Matching co-firing method of ltcc power inductor device substrate and ceramic dielectric material

A technology of ceramic dielectric and power inductor, which is applied in the field of matching co-firing of LTCC power inductor device substrate and ceramic dielectric material to achieve good DC characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

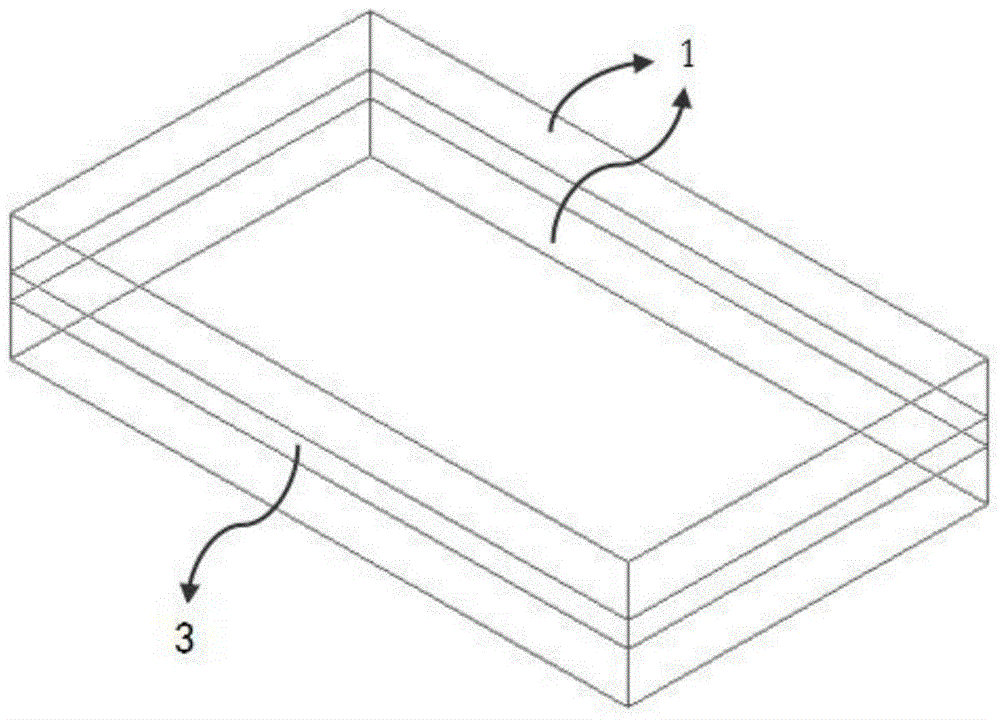

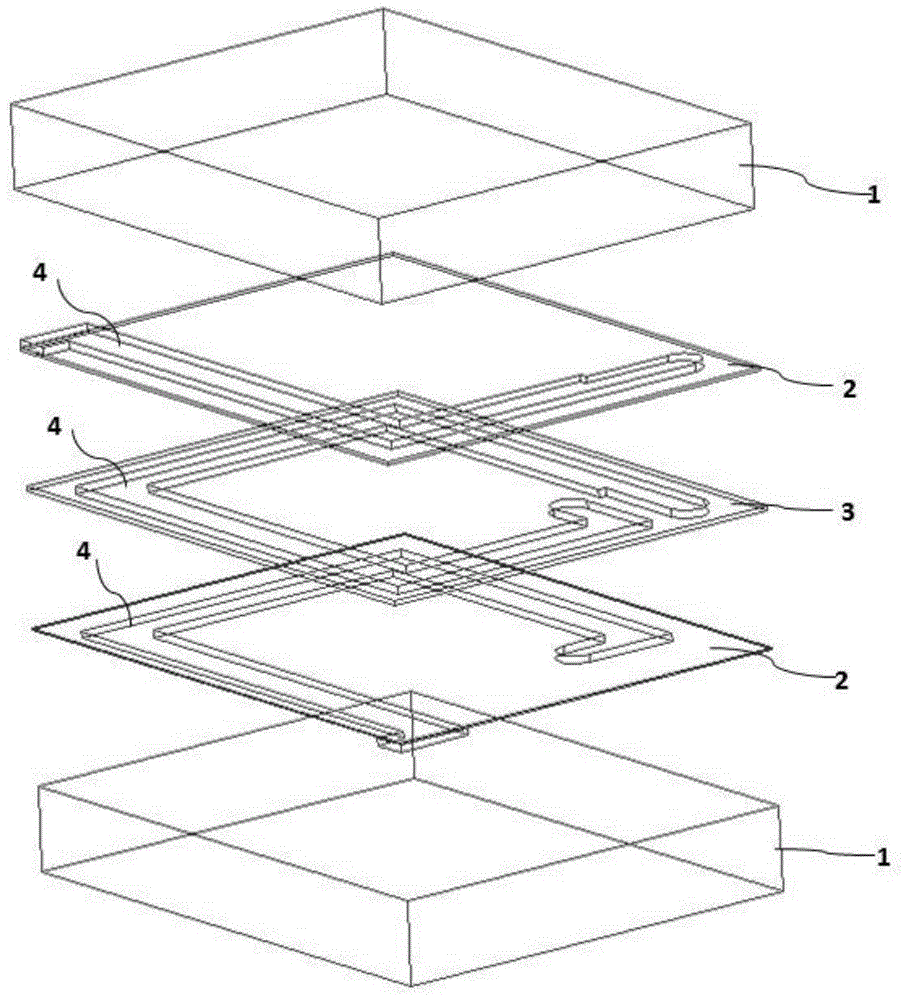

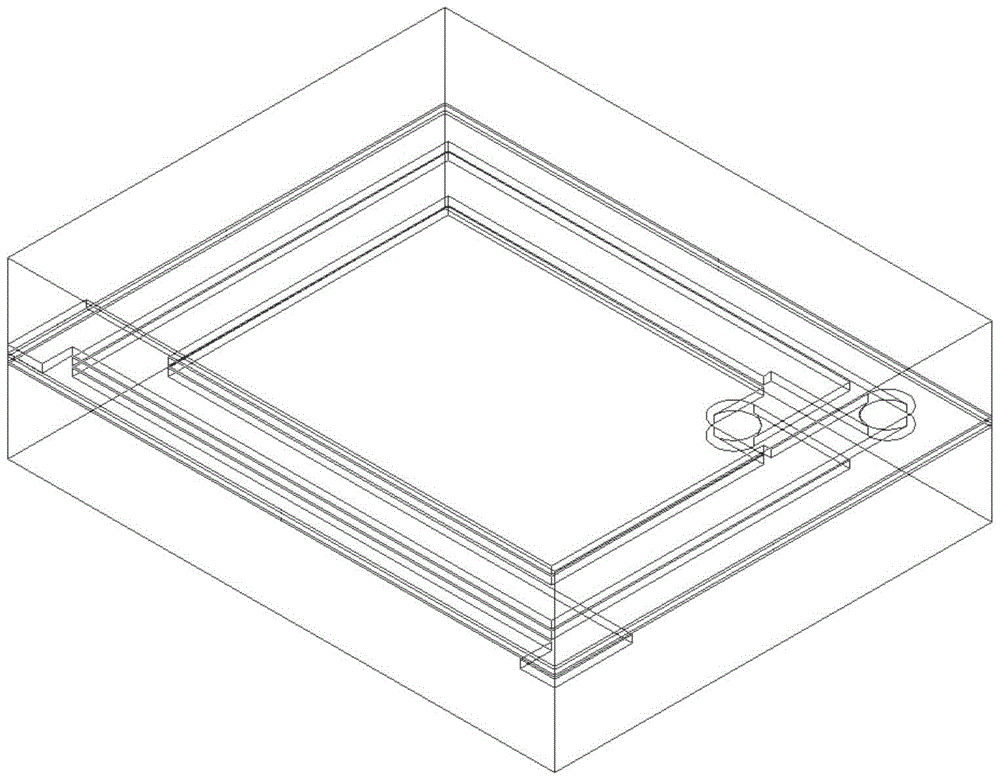

[0033] The invention discloses a matching co-firing method of an LTCC power inductance device base body and a ceramic dielectric material, in which a low-temperature sintered NiCuZn ferrite material and a ceramic silicate material are matched and co-fired through an LTCC wet casting process.

[0034] The NiCuZn ferrite molecular formula described in this embodiment is Ni 0.4 Cu 0.24 Zn 0.47 Fe 1.82 o 4 , taking into account the iron-deficiency formula and the partial volatilization of ZnO at high temperature, in line with MFe 2 o 4 spinel structure.

[0035] Raw materials of NiCuZn ferrite include NiO (purity 99.2%), ZnO (purity 99.5%), CuO (purity 99.5%), Fe 2 o 3 (purity 99.3%), and NiO, ZnO, CuO, Fe 2 o 3 The molar ratio is 20:23.5:12:45.5.

[0036] The dielectric material of ceramic silicate material is Zn 2 SiO 4 Material, the main component is ZnO:SiO 2 It is compounded according to the molar ratio of the main component of 2:1;

[0037]The method further in...

Embodiment 2

[0045] The invention discloses a matching co-firing method of an LTCC power inductance device base body and a ceramic dielectric material, in which a low-temperature sintered NiCuZn ferrite material and a ceramic silicate material are matched and co-fired through an LTCC wet casting process.

[0046] The NiCuZn ferrite molecular formula described in this embodiment is Ni 0.4 Cu 0.24 Zn 0.47 Fe 1.82 o 4 , taking into account the iron-deficiency formula and the partial volatilization of ZnO at high temperature, in line with MFe 2 o 4 spinel structure.

[0047] Raw materials of NiCuZn ferrite include NiO (purity 99.2%), ZnO (purity 99.5%), CuO (purity 99.5%), Fe 2 o 3 (purity 99.3%), and NiO, ZnO, CuO, Fe 2 o 3 The molar ratio is 20:23.5:12:45.5.

[0048] The method further includes the following steps: (1) Preparation of calcined powder: wet-grinding the raw materials of NiCuZn ferrite according to the above-mentioned molar ratio in a grinder using zirconium balls as t...

Embodiment 3

[0057] The invention discloses a matching co-firing method of an LTCC power inductance device base body and a ceramic dielectric material, in which a low-temperature sintered NiCuZn ferrite material and a ceramic silicate material are matched and co-fired through an LTCC wet casting process.

[0058] The NiCuZn ferrite molecular formula described in this embodiment is Ni 0.4 Cu 0.24 Zn 0.47 Fe 1.82 o 4 , taking into account the iron-deficiency formula and the partial volatilization of ZnO at high temperature, in line with MFe 2 o 4 spinel structure.

[0059] Raw materials of NiCuZn ferrite include NiO (purity 99.2%), ZnO (purity 99.5%), CuO (purity 99.5%), Fe 2 o 3 (purity 99.3%), and NiO, ZnO, CuO, Fe 2 o 3 The molar ratio is 20:23.5:12:45.5.

[0060] The method further includes the following steps: (1) Preparation of calcined powder: wet-grinding the raw materials of NiCuZn ferrite according to the above-mentioned molar ratio in a grinder using zirconium balls as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com