Slurry for electrode catalyst layer of fuel cell, electrode catalyst layer, membrane electrode assembly, and fuel cell

A fuel cell electrode and catalyst layer technology, applied to fuel cell parts, fuel cells, battery electrodes, etc., can solve the problems that protons cannot reach the three-phase interface, hinder the supply of reaction gas, and hinder the supply of gas, etc., to achieve gas diffusion Excellent performance and water retention, excellent gas diffusivity, and easy gas diffusivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0080] [Preparation of slurry for catalyst layer]

[0081] Put platinum-supported carbon (TEC10E50E, manufactured by Tanaka Kikinzoku Co., Ltd.) in a container, add water, and mix. Then, ethyl acetate and electrolyte 13 (Nafion (R) (registered trademark) dispersion liquid, Wako Pure Chemical Industries, Ltd.) in the same amount as water were added and stirred to obtain a catalyst layer slurry.

[0082] In addition, the composition ratio of the said slurry for catalyst layers is as follows.

[0083] Platinum-loaded carbon... 20.0 parts by mass

[0084] Electrolyte... 10.0 parts by mass

[0085] Water 135.0 parts by mass

[0086] Ethyl acetate... 135.0 parts by mass

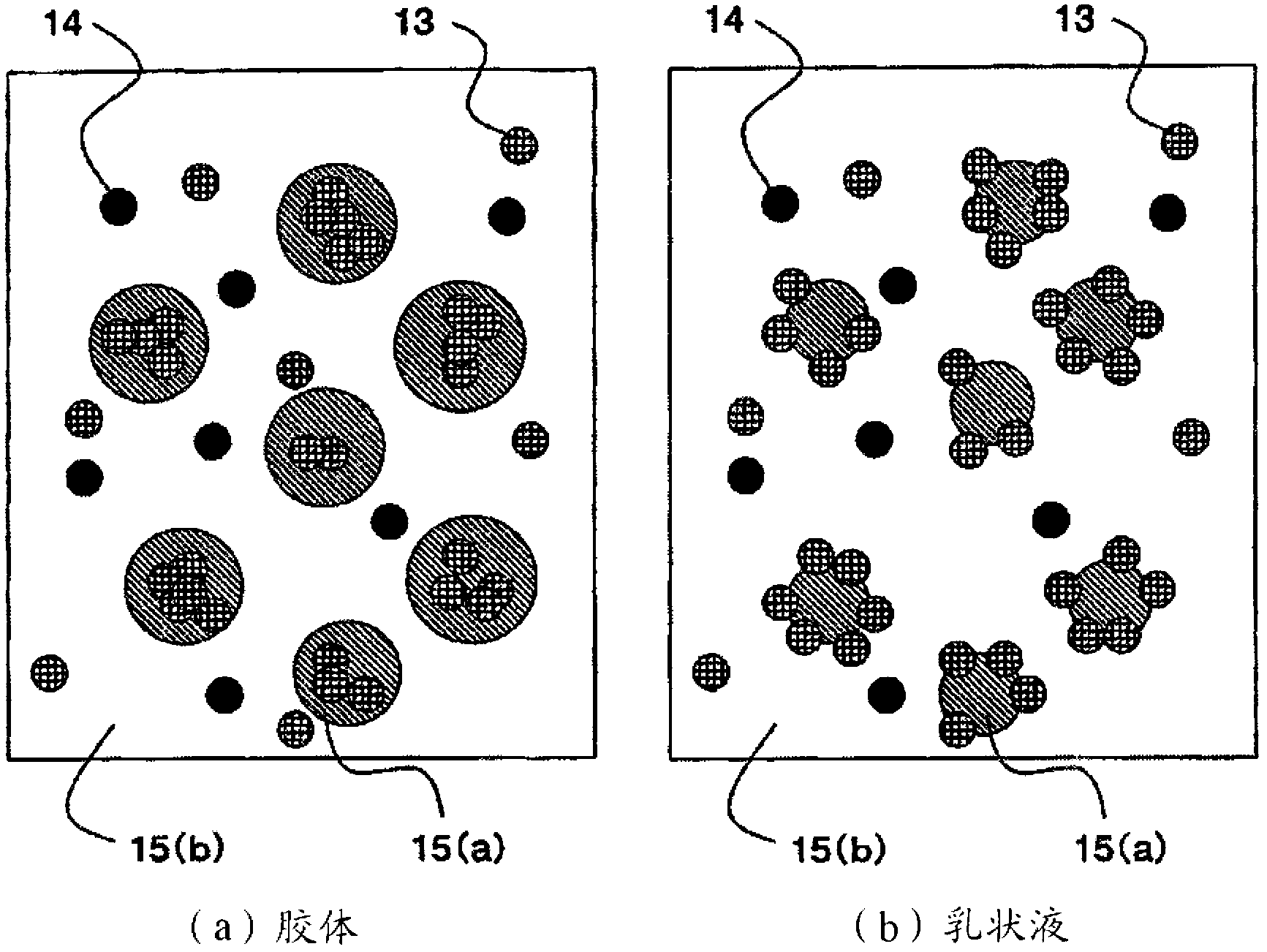

[0087] The mixed solution of water and ethyl acetate undergoes phase separation, and the mixed solution of electrolyte and solvent forms a colloid.

[0088] [Manufacturing of Membrane Electrode Assembly]

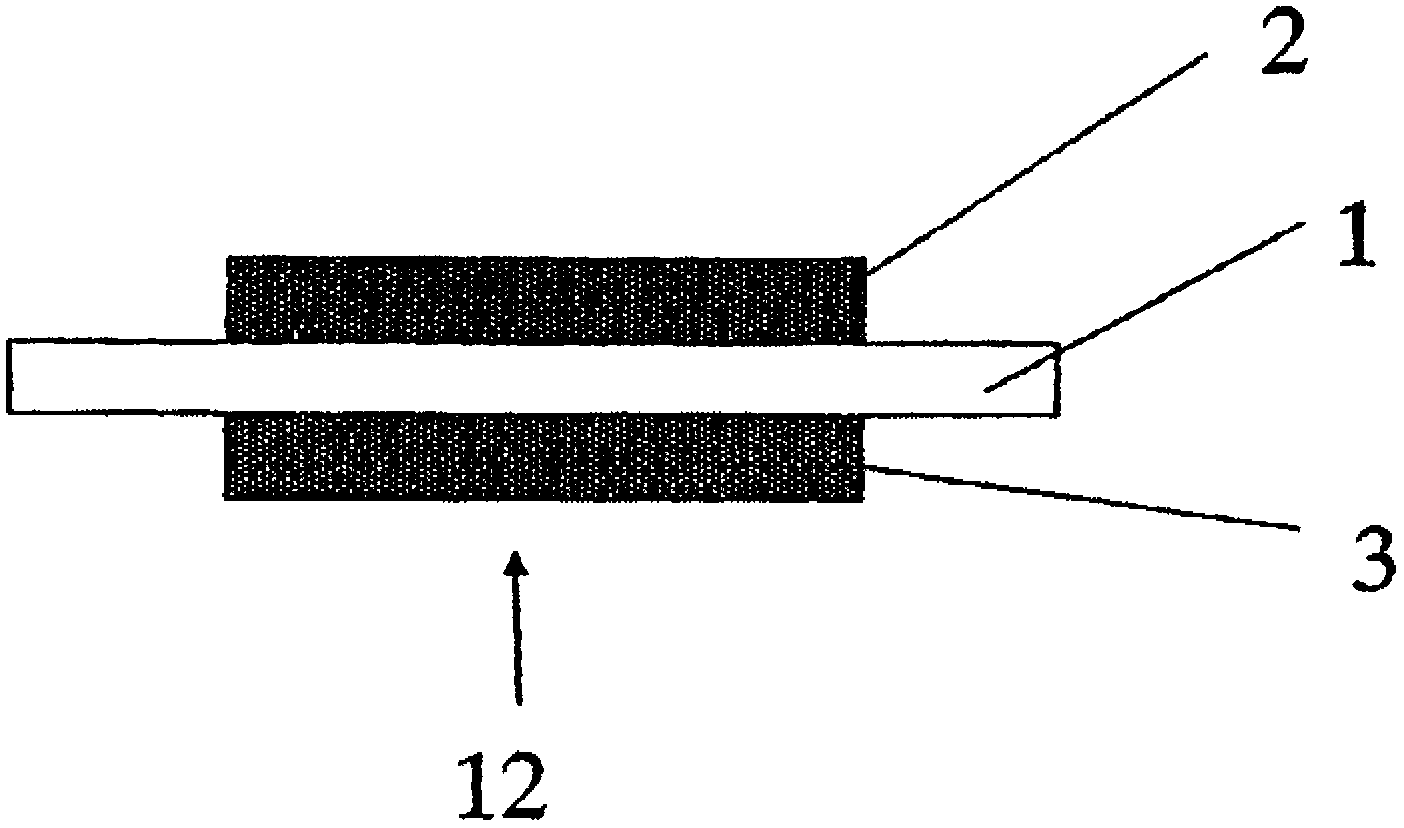

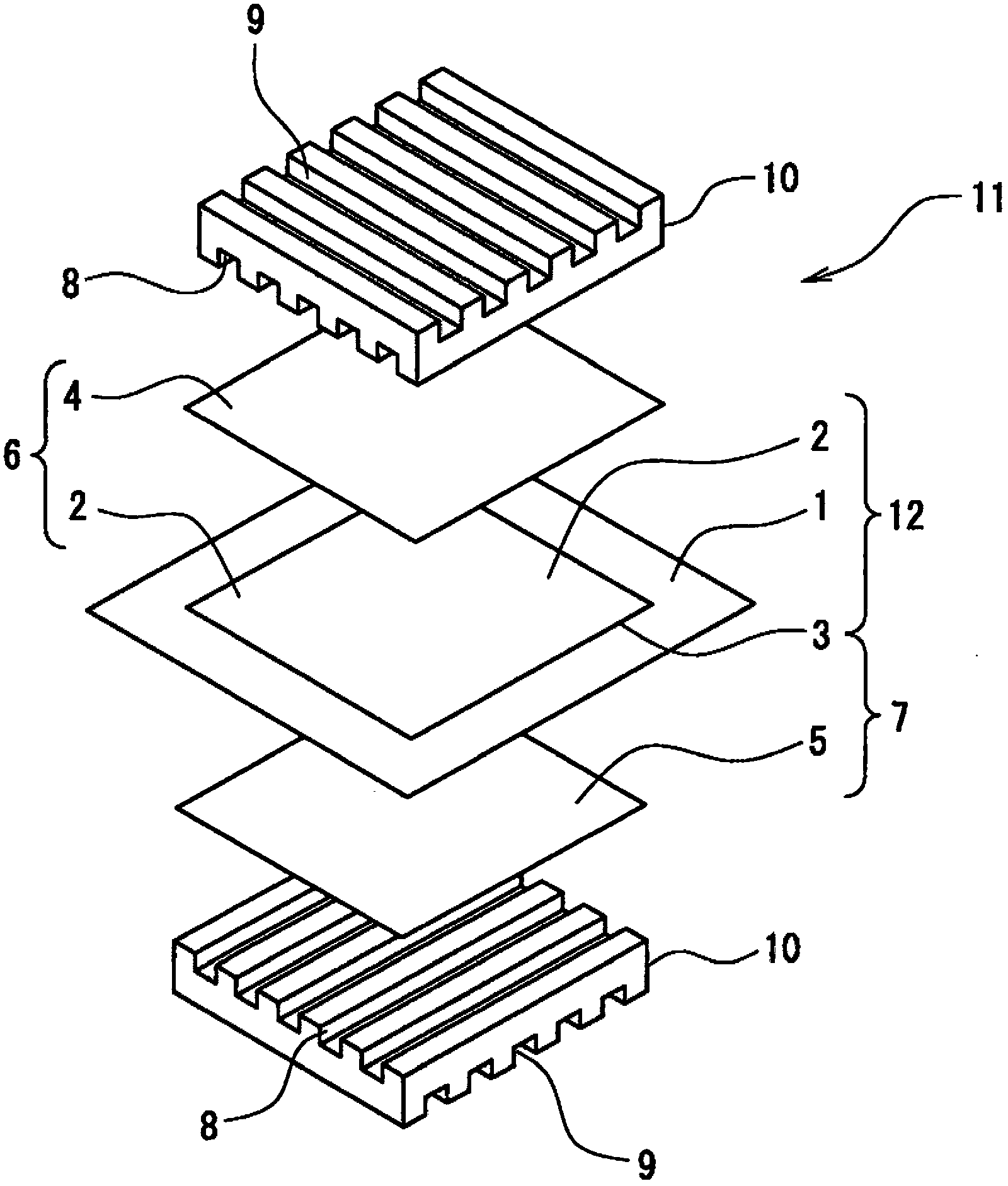

[0089] The catalyst layer slurry was coated on a polytetrafluoroethylene membrane (PTFE membrane) and th...

Embodiment 2

[0091] A catalyst layer slurry was prepared in the same manner as in Example 1, except that ethyl acetate was used in a mass three times that of water.

[0092] The mixed solution of water and ethyl acetate undergoes phase separation, and the mixed solution of electrolyte and solvent forms an emulsion.

[0093] Membrane electrode assemblies were fabricated by the same method as in Example 1, and power generation performance was evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com