Continuously discharging reboiler

A technology of reboiler and discharge port, applied in the field of continuous discharge reboiler, can solve the problems of slow heating speed, small heating area at the bottom, complicated process, etc., and achieve the effect of convenient discharging and convenient temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

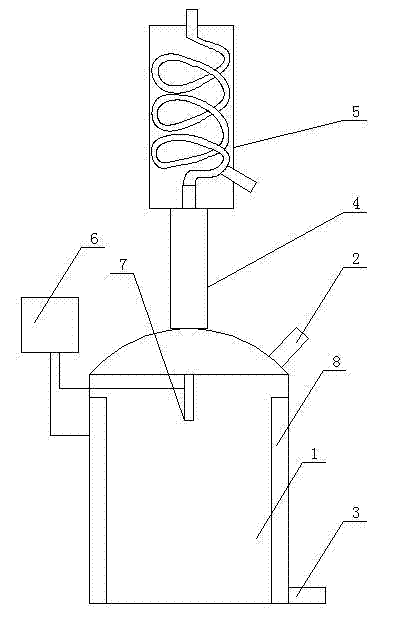

[0014] as attached figure 1 Shown: the continuous discharge reboiler of the present invention comprises tower still 1, and described tower still has heating device inside, and described tower still has feeding port 2 above, and below has discharge port 3, and described tower A rectification column 4 is connected above the kettle, and a reflux pipe 5 is connected above the rectification column, and a temperature sensor 6 is installed inside the tower kettle, and the temperature sensor is connected to a thermostat 7, and the thermostat is connected to the heating device.

Embodiment 2

[0016] In the continuous discharging reboiler, the heating device adopts electric rod 8 .

Embodiment 3

[0018] In the continuous discharge reboiler, the return pipe adopts a serpentine return pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com