Method for manufacturing large titanium alloy fan damping platform blade blank

A technology of titanium alloy and damping table, which is applied in the field of forging, can solve the problems that the surface quality of the blank cannot be guaranteed, the heating temperature cannot be accurately controlled, and the consumption of raw materials is increased, so as to eliminate surface oxidation, improve surface quality, and reduce consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

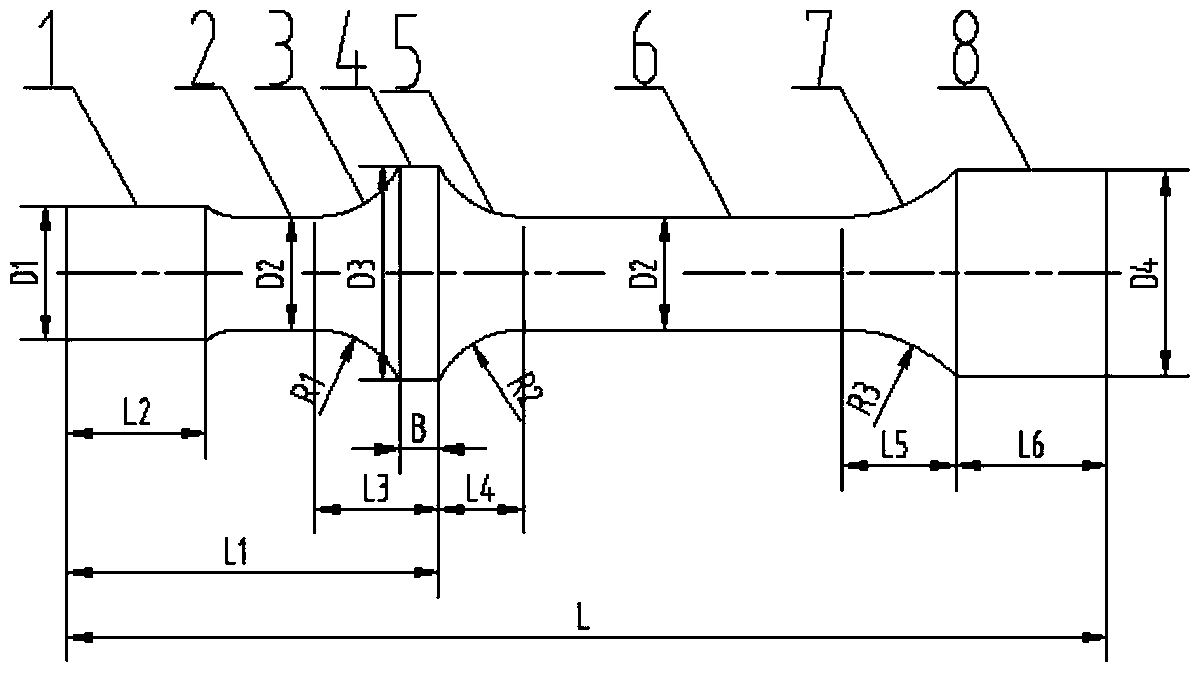

[0103] Dimensions of the top forging of a large titanium alloy fan damping platform blade:

[0104] D1=φ84.7mm; D2=φ70.6mm; D3=φ135mm; D4=φ129mm; D5=φ91.7mm;

[0105] D6=φ84.7mm; D7=φ74.6mm; D8=φ106.8mm; D9=φ82.7mm;

[0106] L=655.2mm; L1=233.9mm; L2=87.7mm; L3=77.7mm; L4=53.5mm; L5=71mm;

[0107] L6=95.8mm;

[0108] R1=60.5mm; R2=60.5mm; R3=100.8mm;

[0109] B=24.2mm;

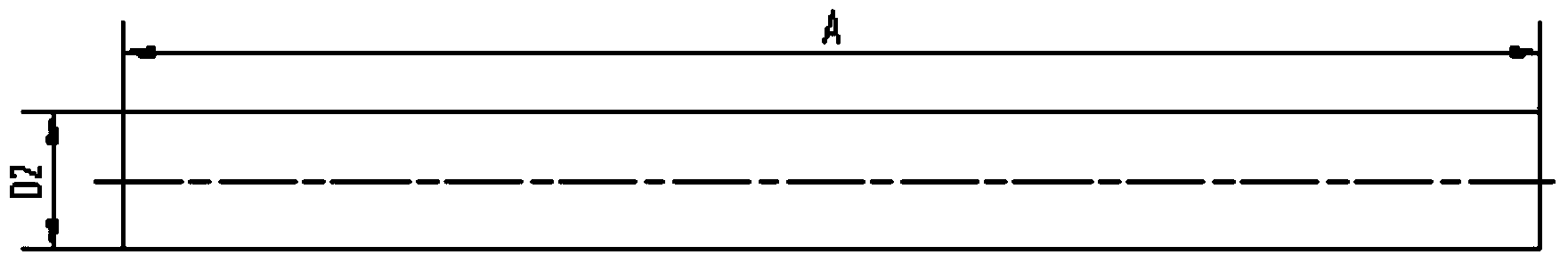

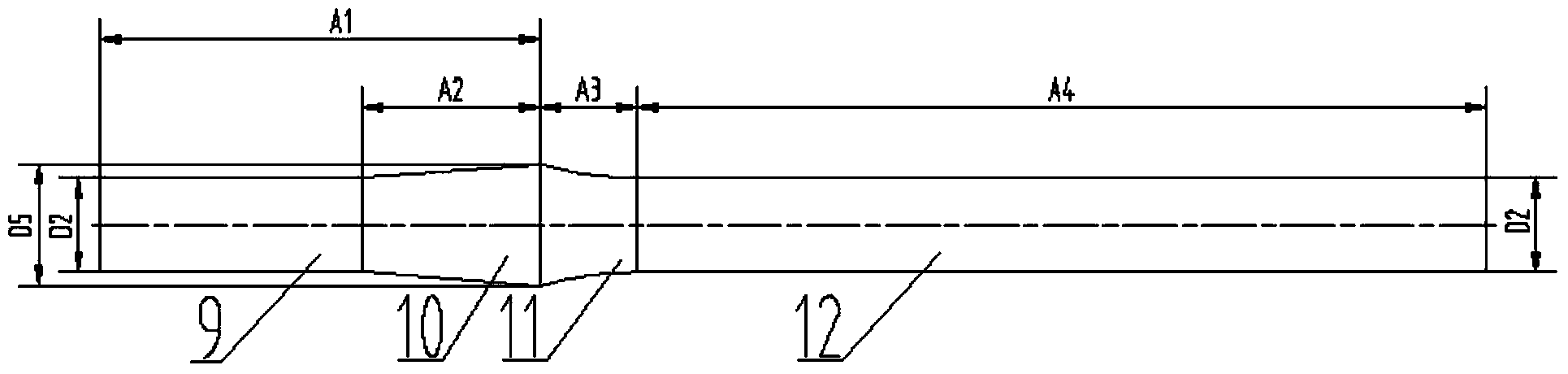

[0110] A=1096mm;A1=330.5mm;A2=133.6mm;A3=73mm;A4=637.3mm;A5=102.8mm;

[0111] A6=251mm;A7=842.3mm;A8=84.5mm;A9=178.9mm;A10=752mm;

[0112] Heating temperature: 920°C, holding time 30 minutes.

Embodiment 2

[0114] Dimensions of the top forging of a large titanium alloy fan damping platform blade:

[0115] D1=φ90mm; D2=φ73.6mm; D3=φ130mm; D4=φ135mm; D5=φ95.7mm;

[0116] D6=φ88.3mm; D7=φ78mm; D8=φ112.3mm; D9=φ86.5mm;

[0117]L=670mm; L1=235mm; L2=88mm; L3=75mm; L4=52mm; L5=73mm;

[0118] L6=98mm;

[0119] R1=65mm; R2=65mm; R3=110mm;

[0120] B=22mm;

[0121] A=1120mm;A1=340mm;A2=135mm;A3=77mm;A4=640mm;A5=106mm;

[0122] A6=256mm;A7=852mm;A8=87mm;A9=182mm;A10=759mm;

[0123] Heating temperature: 960°C, holding time 35 minutes.

Embodiment 3

[0125] Dimensions of the top forging of a large titanium alloy fan damping platform blade:

[0126] D1=φ84.7mm; D2=φ65mm; D3=φ135mm; D4=φ129mm; D5=φ87.8mm;

[0127] D6=φ78mm; D7=φ74.6mm; D8=φ107.7mm; D9=φ87mm;

[0128] L=655.2mm; L1=233.9mm; L2=87.7mm; L3=77.7mm; L4=53.5mm; L5=71mm;

[0129] L6=95.8mm;

[0130] R1=60.5mm; R2=60.5mm; R3=100.8mm;

[0131] B=24.2mm;

[0132] A=1105mm;A1=350.5mm;A2=148.6mm;A3=80mm;A4=665mm;A5=109.2mm;

[0133] A6=263.4mm;A7=851.3mm;A8=90.6mm;A9=185.3mm;A10=761mm;

[0134] Heating temperature: 940°C, holding time 25 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com