Method for strengthening molded surface of auto-body panel forming die by induction heat quenching

A technology for automobile body and forming molds, applied in quenching devices, furnace types, heat treatment furnaces, etc., can solve problems such as uneven failure process and uneven load distribution, and achieve the effect of increasing mold life and shortening mold manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Below in conjunction with specific embodiment, the present invention is further described:

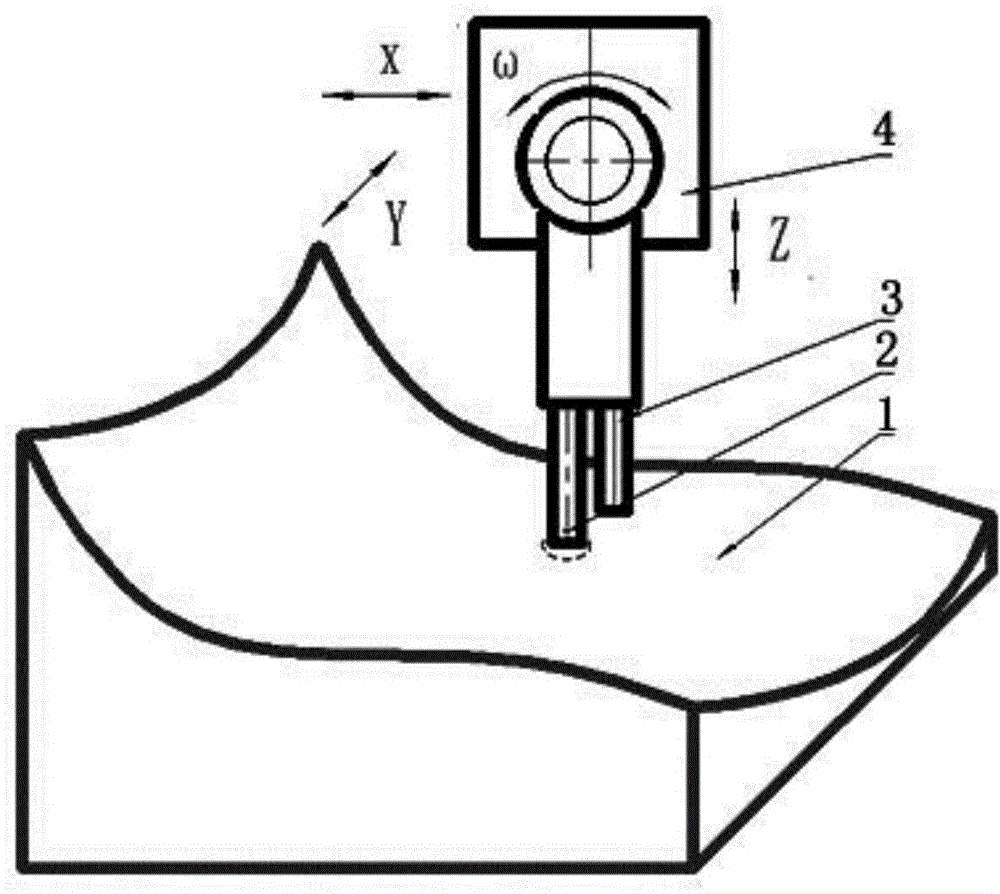

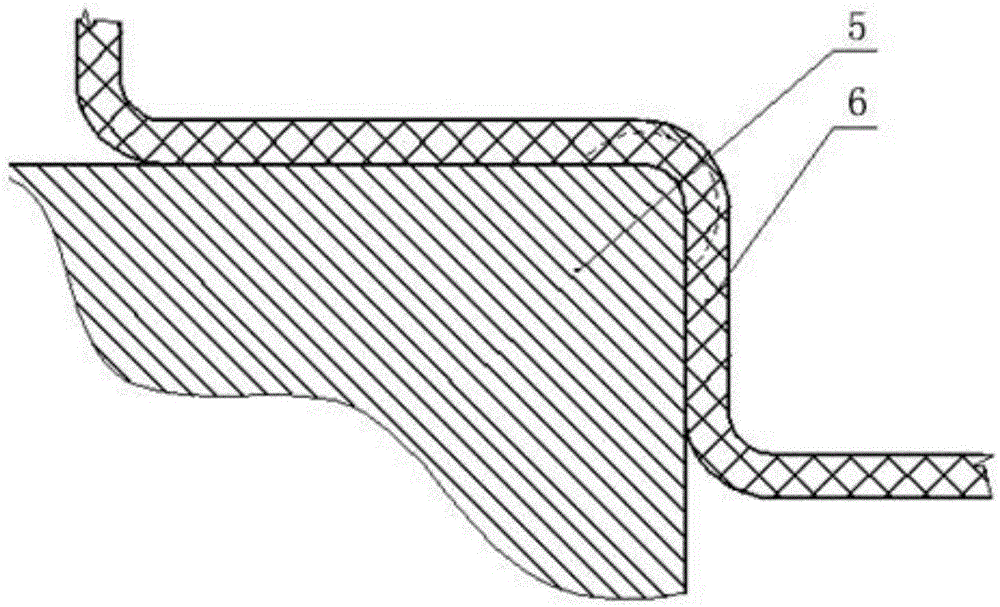

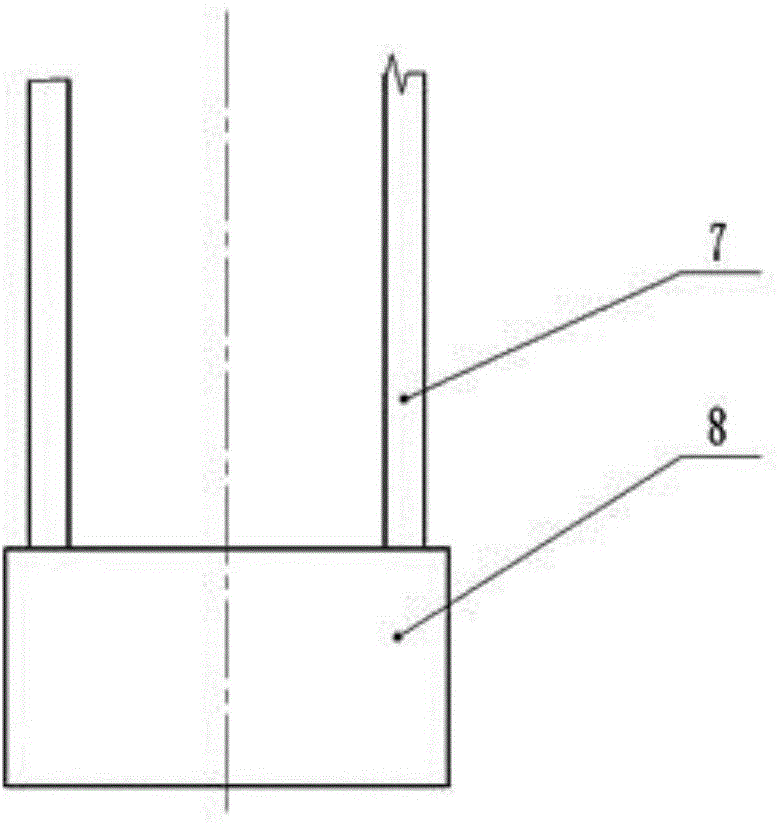

[0048] Such as Figure 1 to Figure 5 The shown automobile body panel forming die surface induction heating quenching strengthening method includes the following steps:

[0049]Before the implementation of the enhanced process method, process planning must be carried out. The planning work includes the design of the moving path of the inductor, the selection of the induction heating power supply parameters, the determination of the cooling liquid supply parameters, the determination of the moving speed of the induction heating and cooling liquid nozzle, and the structural design of the induction heater. with production.

[0050] After the design work is completed, the implementation of the process plan begins, including: preparing the induction heating power supply and cooling water supply device, making the induction heater and the driving device, integrating the induction heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com