Apparatus and method for treating waste steam discharged from decoking step of delayed coking process

A delayed coking and processing device technology, applied in chemical instruments and methods, combined devices, separation methods, etc., to achieve the effects of reducing pollution, improving the environment, and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

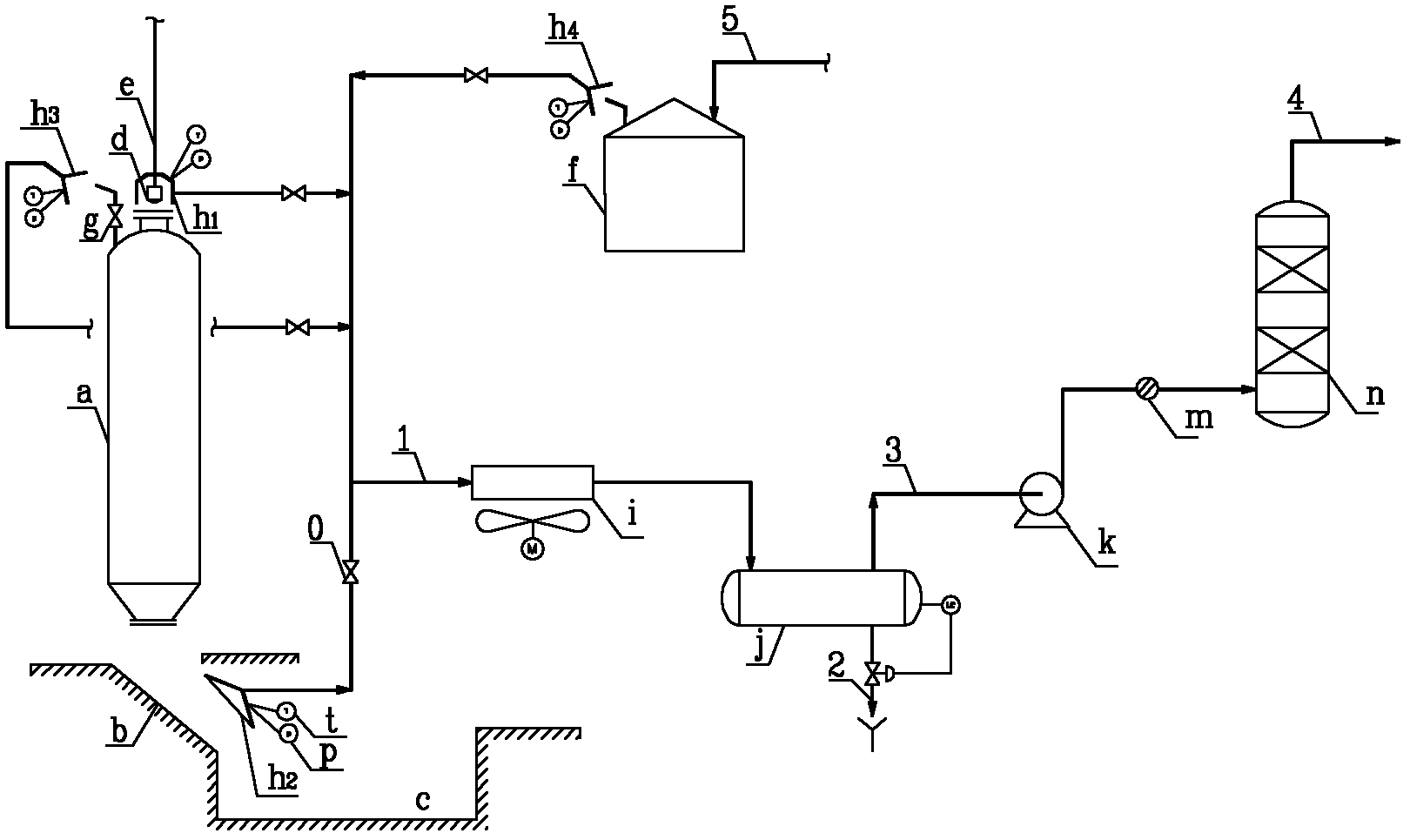

[0031] Such as figure 1 As shown, a delayed coking decoking exhaust steam treatment device.

[0032] Including: steam collection hood, steam cooler i, liquid separation tank j, induced draft fan k, coke powder filter m and desulfurization tank n, steam collection is installed at each port where oil-containing, sulfur-containing and coke powder-containing steam 1 is discharged Hood: top steam collection hood h 1 , Bottom steam collection hood h 2 , Breathing valve steam collection cover h 3 and cold coke hot water tank steam collection cover h 4 , respectively installed on the top of the coke tower a, above the chute b, the outlet of the breathing valve g on the top of the coke tower, and the top of the cold coke hot water tank f, and a shut-off valve o is set for each road, so that one of them can be cut off when no steam is discharged. Among them, the tower top steam collection hood h 1 There is an opening at the top, and the coke cutter d and the drill pipe e can pass t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com