Locating structure for linear motor of PCB (Printed Circuit Board) drilling machine

A technology of linear motor and positioning structure, which is applied to drilling/drilling equipment, large fixed members, components of boring machine/drilling machine, etc. Reduce the effect of part deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

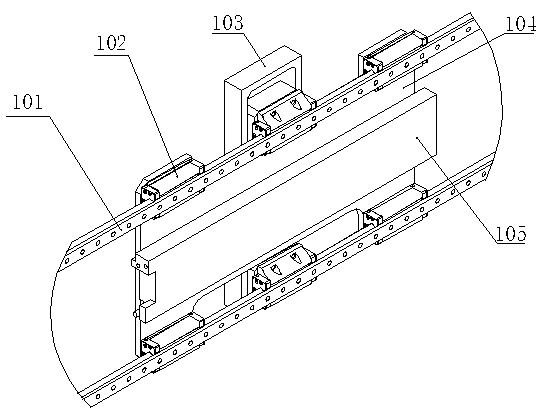

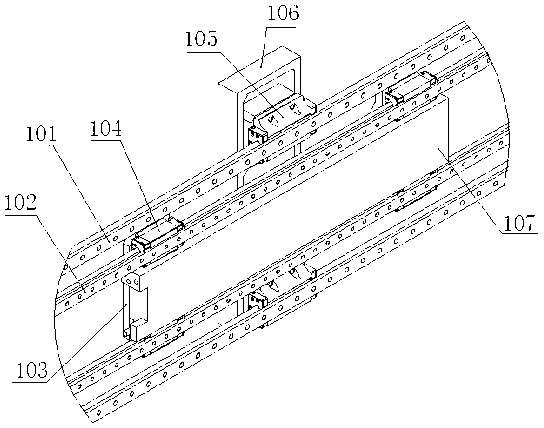

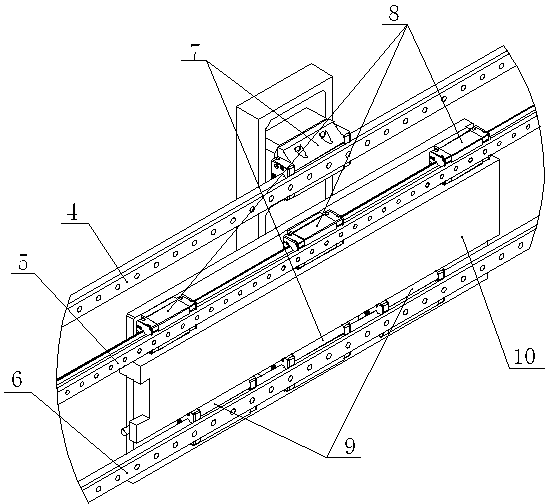

[0023] Such as image 3 and Figure 4 As mentioned above, the linear guide rail 4 of the base plate, the linear guide rail 5 of the fixed plate, and the shared linear guide rail 6 are respectively fixed on the marble beam, and the Z-axis base plate 2 is respectively connected to the linear guide rail 4 of the base plate and the shared linear guide rail 6 through two sliders 7. Swipe left and right. The linear motor 10 is connected on the motor fixing plate 1 by screws, and the motor fixing plate 1 is respectively connected to the fixing plate linear guide rail 5 and the shared linear guide rail 6 through three sliders 8 and two sliders 9 to realize left and right sliding. The motor fixing plate 1 and the Z-axis bottom plate 2 are connected through two X-axis connecting blocks 3 to realize power transmission. The motor fixing plate 1 and the Z-axis bottom plate 2 share a common linear guide rail 6 at one end, which can reduce the deformation of parts caused by the suction for...

Embodiment 2

[0025] The rest are the same as in Embodiment 1, except that the motor fixing plate 1 is respectively connected to the fixing plate linear guide rail 5 and the common linear guide rail 6 through four sliders 8 and four sliders 9 to realize left and right sliding. The size of the motor fixing plate 1 is set according to the size of the linear motor 10 , and the number of sliders is set according to the size of the motor fixing plate 1 .

Embodiment 3

[0027] The rest is the same as that of Embodiment 1, except that the motor fixing plate 1 and the Z-axis bottom plate 2 are connected through four X-axis connecting blocks 3 to realize power transmission. According to the different sizes of the motor fixing plate 1 and the Z-axis base plate 2 , the number of X-axis connecting blocks 3 can be set to effectively connect the motor fixing plate 1 and the Z-axis base plate 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com