Rivet press assembling mechanism

A technology of assembling mechanism and pressing mechanism, applied in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of flexible mechanism, high degree of automation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

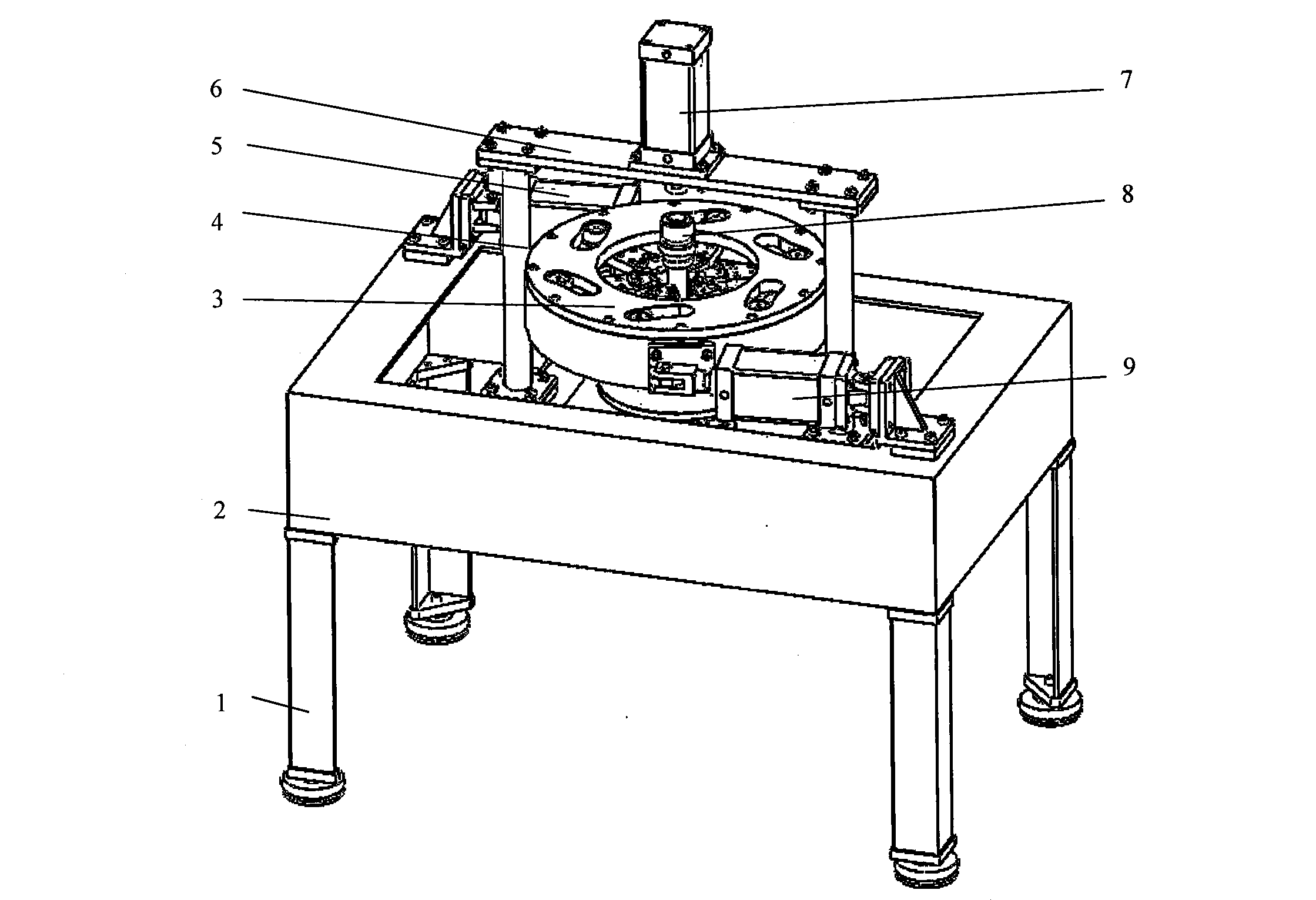

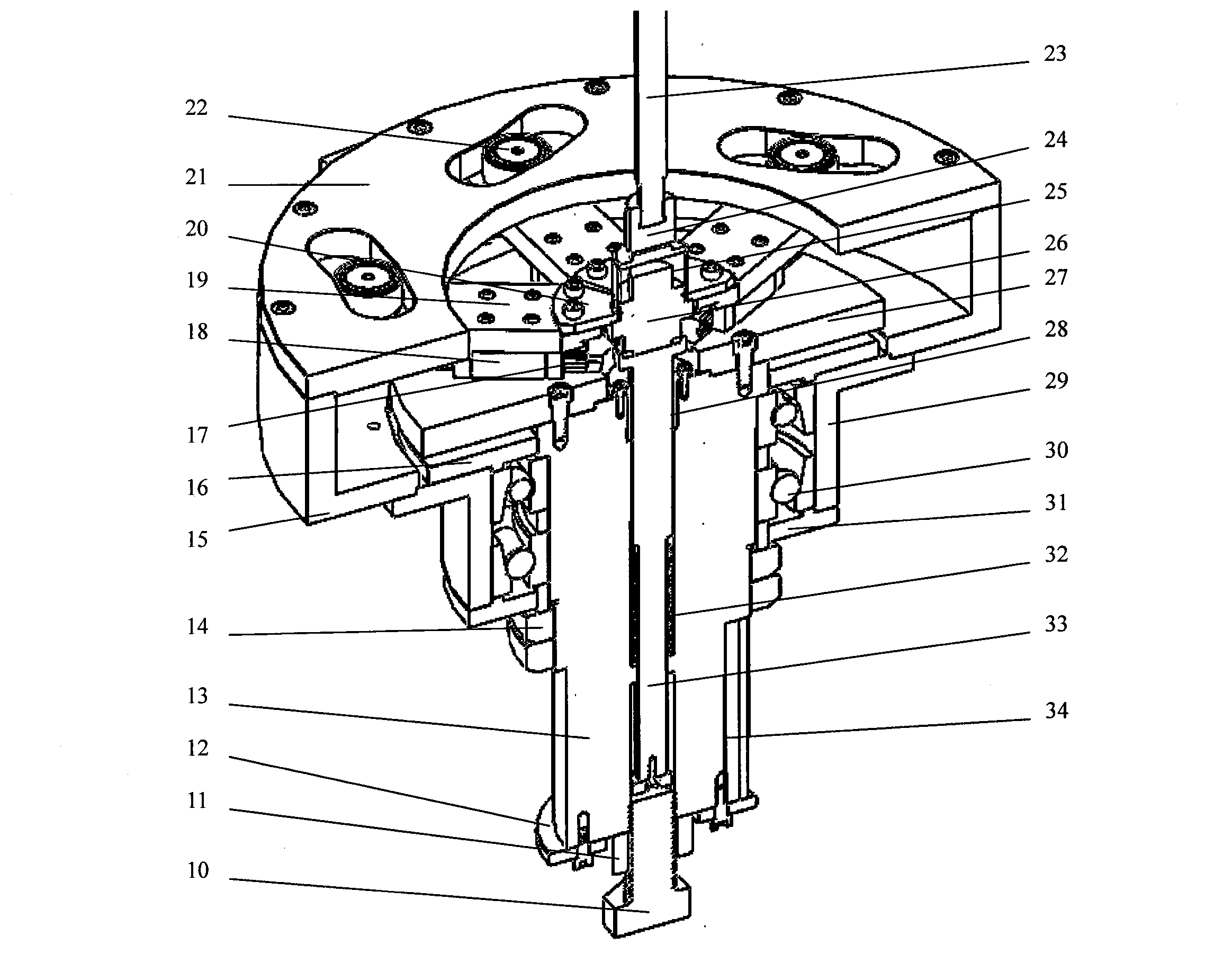

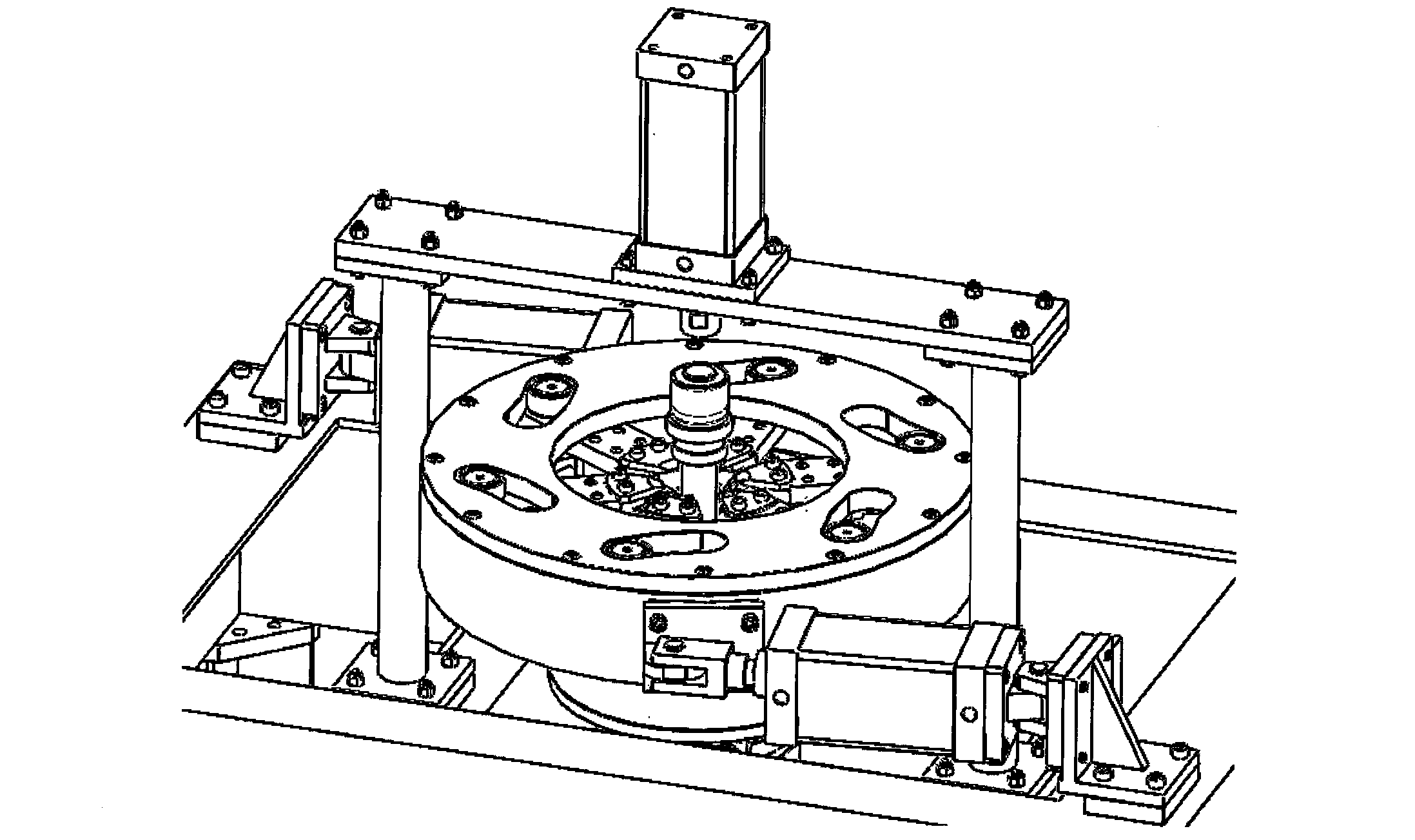

[0013] see figure 1 and this figure 2 , the present invention mainly is made up of stand, pressing mechanism, riveting mechanism.

[0014] The bench is composed of a foot 1 and a base 2. The base 2 is usually in the form of a steel welded frame, which can be designed according to the size of the riveted piece and the specific requirements of the riveting pressure.

[0015] Column 4 in the compression mechanism, compression cylinder support plate 6, compression cylinder 7 are rigid connection, are fixed on the base 2. When the compression cylinder piston rod 23 is stretched out, the riveting part housing 25 and the riveting part main body 26 are assembled and pressed by the nylon sleeve 24 installed on its front end (the nylon sleeve plays the role of buffering and shock absorption, and is convenient for replacement). tight. Since the central support rod 33, the oil-free bushing 28, and the spring 32 are installed in the shaft hole of the central shaft 13, with the pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com