Prefabricated reaction tank for biological contact oxidation for sewage pretreatment

A biological contact and sewage treatment technology, applied in the direction of aerobic process treatment, sustainable biological treatment, etc., can solve problems such as uneven water distribution and aeration, improper design or operation, plugging of fillers, etc., to achieve convenient operation and management, production The effect of mature technology and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

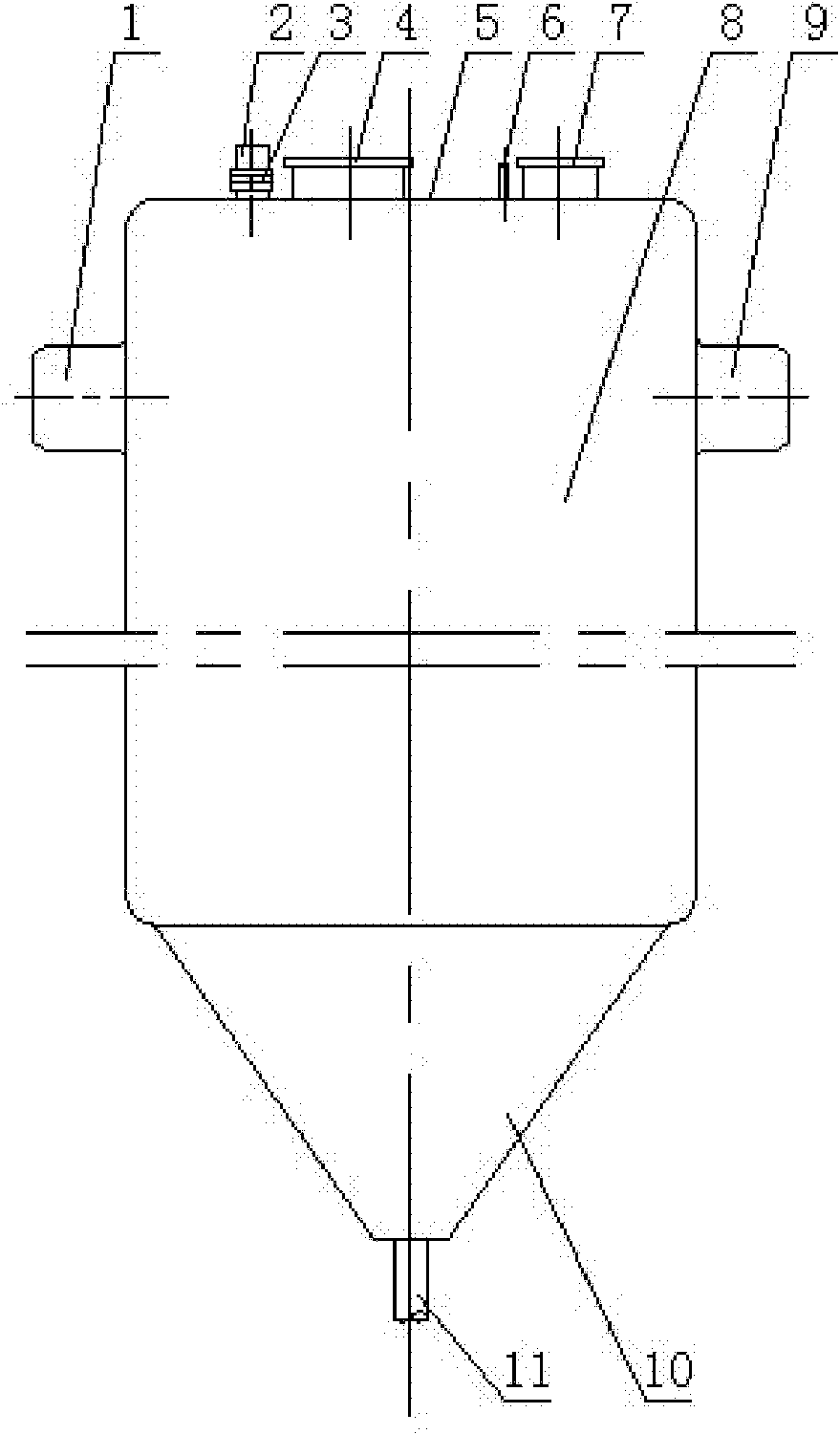

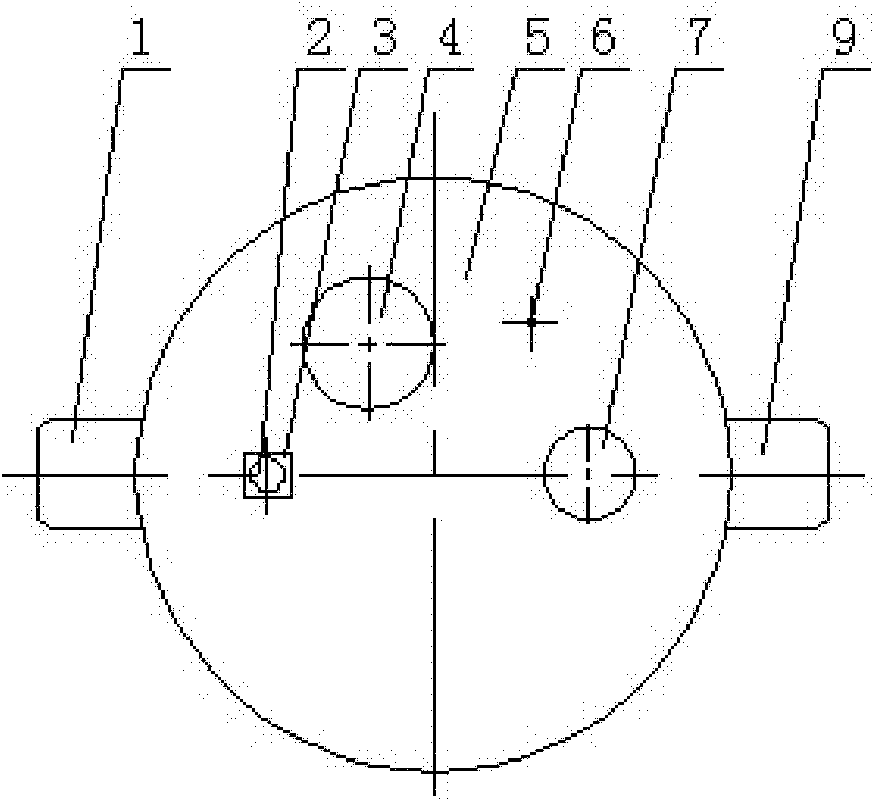

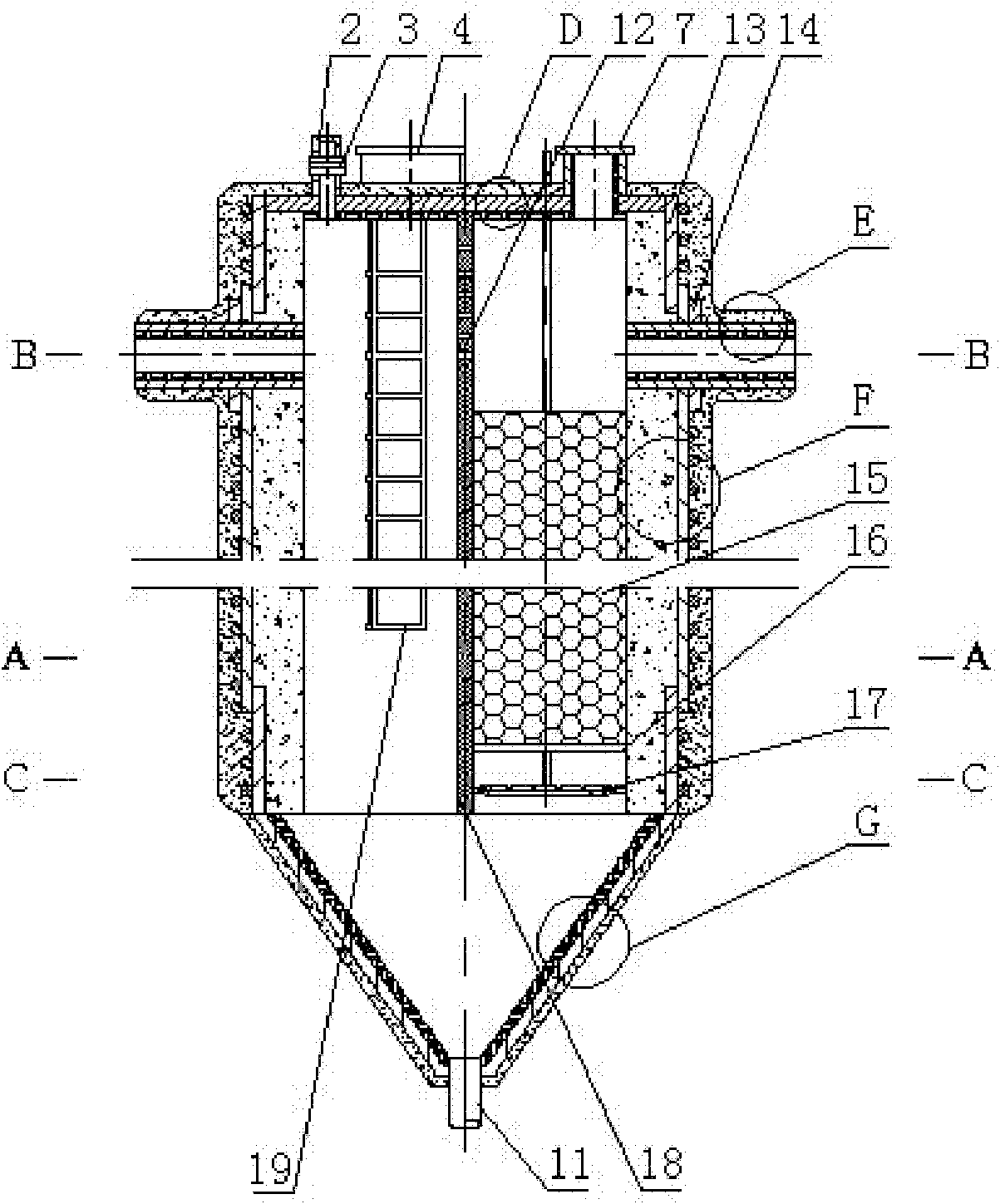

[0034] A prefabricated biological contact oxidation reaction tank for sewage treatment, comprising a cylindrical tank body 8, a tank top plate 5 and an inverted conical mud collecting bucket 10, the upper end of the cylindrical tank body is fixed to the tank body top plate, and the cylindrical tank body The lower end and the upper end of the inverted conical mud collecting bucket are fixed. The top plate of the tank body is composed of a roof steel plate 25, an outer protective layer 24 of the roof and an inner protective layer 26 of the roof. The outer protective layer of the roof is fixed on the outer wall of the roof steel plate, and the inner protective layer of the roof is fixed Installed on the inner wall of the roof steel plate, the outer protective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com