Sealing frame of furnace frame sealing device

A technology of sealing device and sealing frame, which is used in the heating of coke ovens, doors/closures of coke ovens, coke ovens, etc. Strength, good sealing effect, damage isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

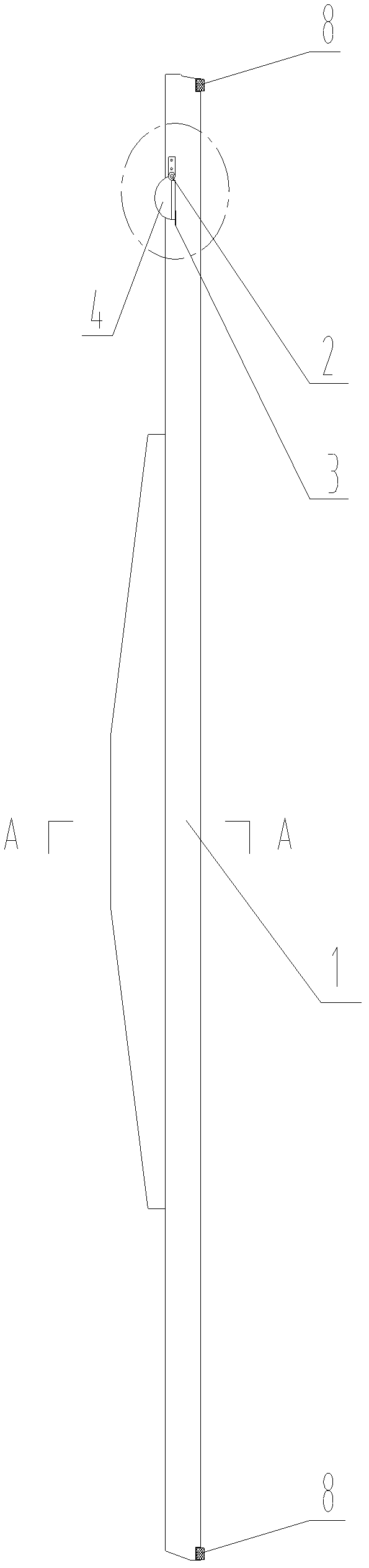

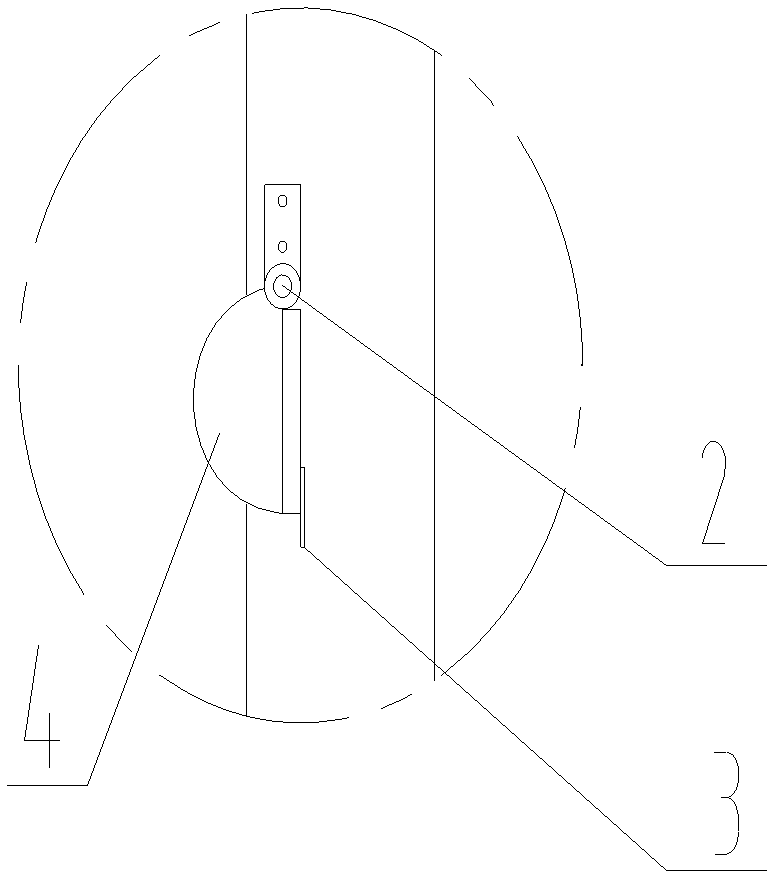

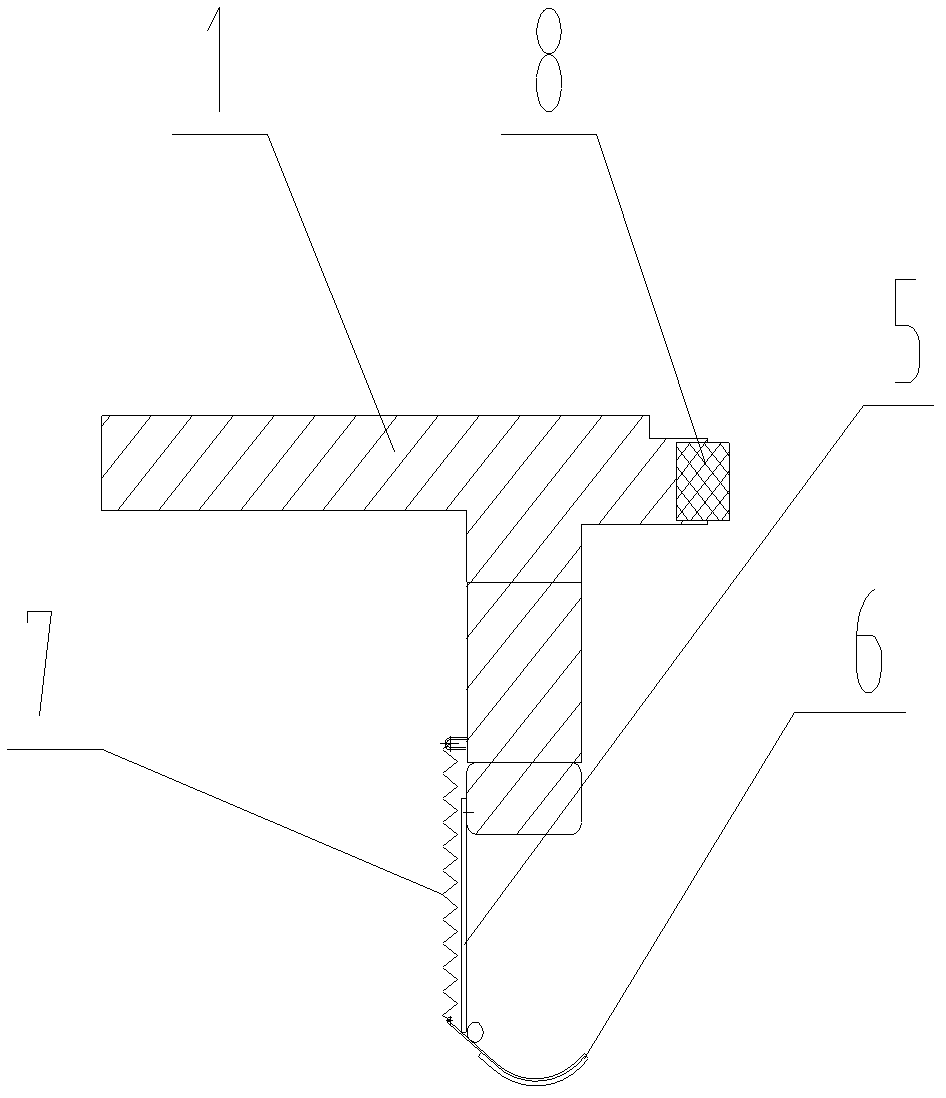

[0011] Such as Figure 1~3 As shown, a sealing frame of a furnace frame sealing device, the sealing frame is a truss structure, and asbestos 8 is installed on the front end of the sealing frame as a whole. The sealing frame includes a frame 1 on both sides. A shaft 2 is vertically arranged on the upper part of the frame 1 on both sides. A liner 3 is hoisted on the shaft 2 through a hinge. The two ends of the liner 3 are provided with a semicircular arc plate 4; The installation position depends on the height of the briquette. During the coal loading process, the top of the briquette is first in contact with the lining plate 3, and then the top of the rear baffle plate of the coal tank of the coal loading vehicle is tamped and then in contact with the semicircular arc plate 4, so that it can be ensured that during the entire coal loading process, The ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com