Preparation system and method of gallium nitride-based materials and devices

A gallium nitride-based, preparation system technology, applied in the field of microelectronics, can solve problems such as the difficulty of growing gallium nitride materials, lattice mismatch thermal mismatch, cracking of gallium nitride materials, etc., to reduce the current collapse effect, The effect of avoiding surface oxidation problems and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

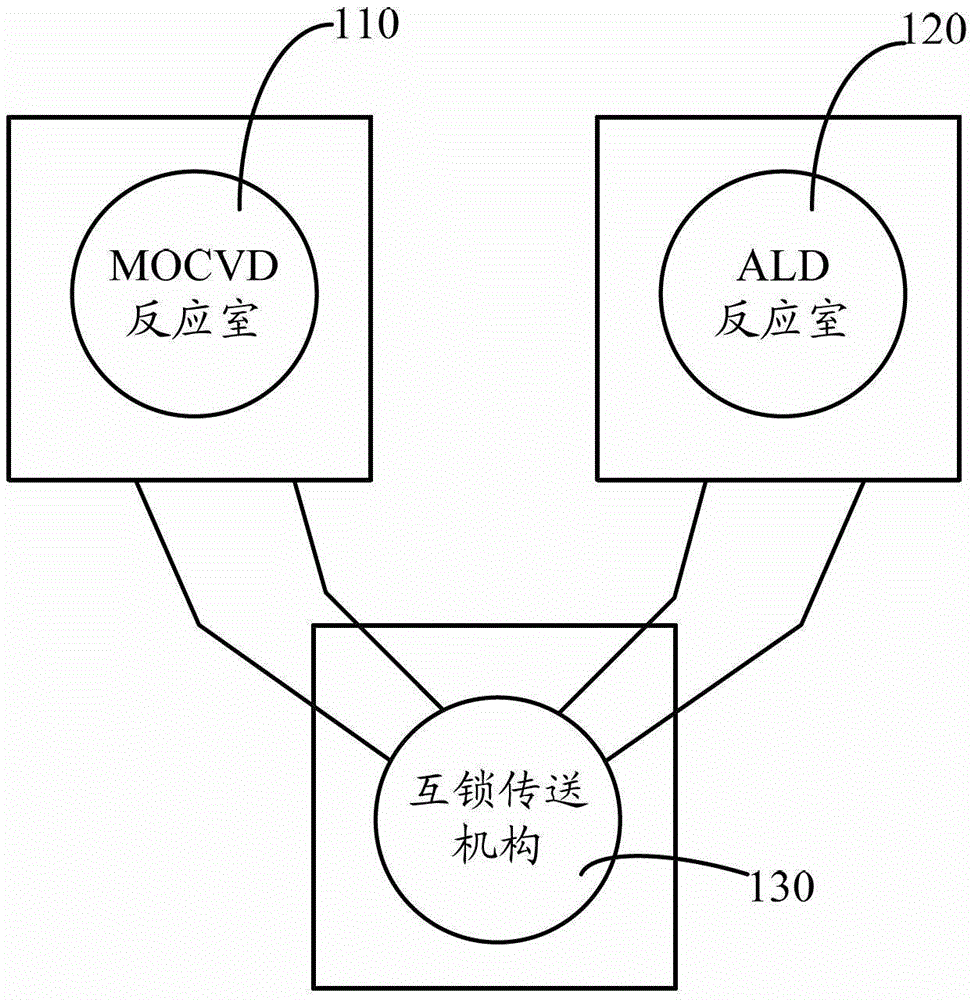

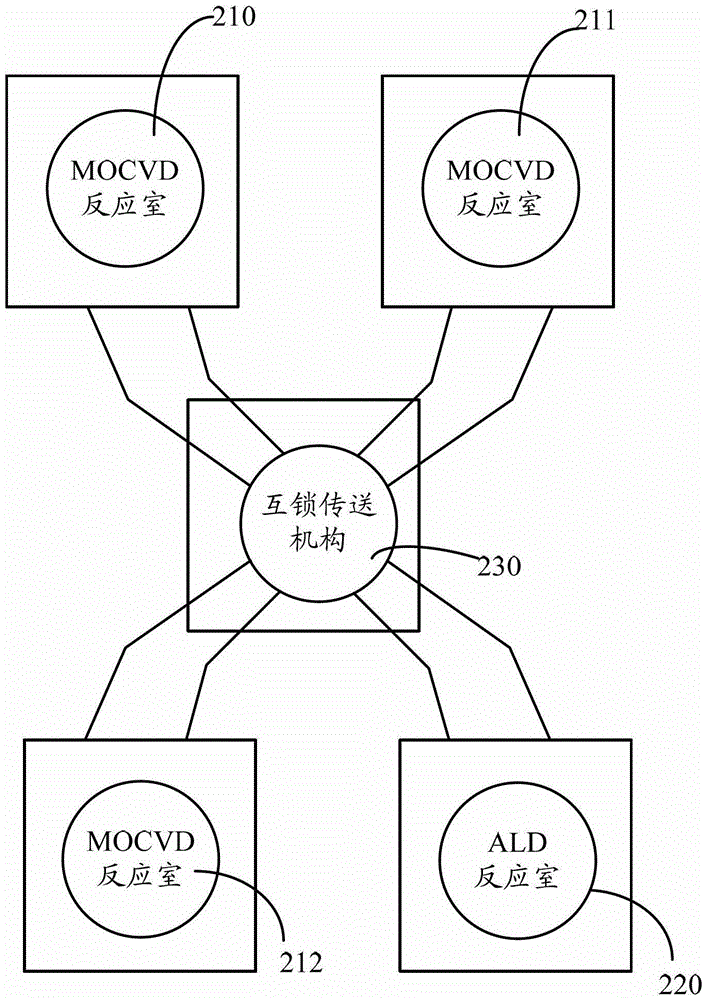

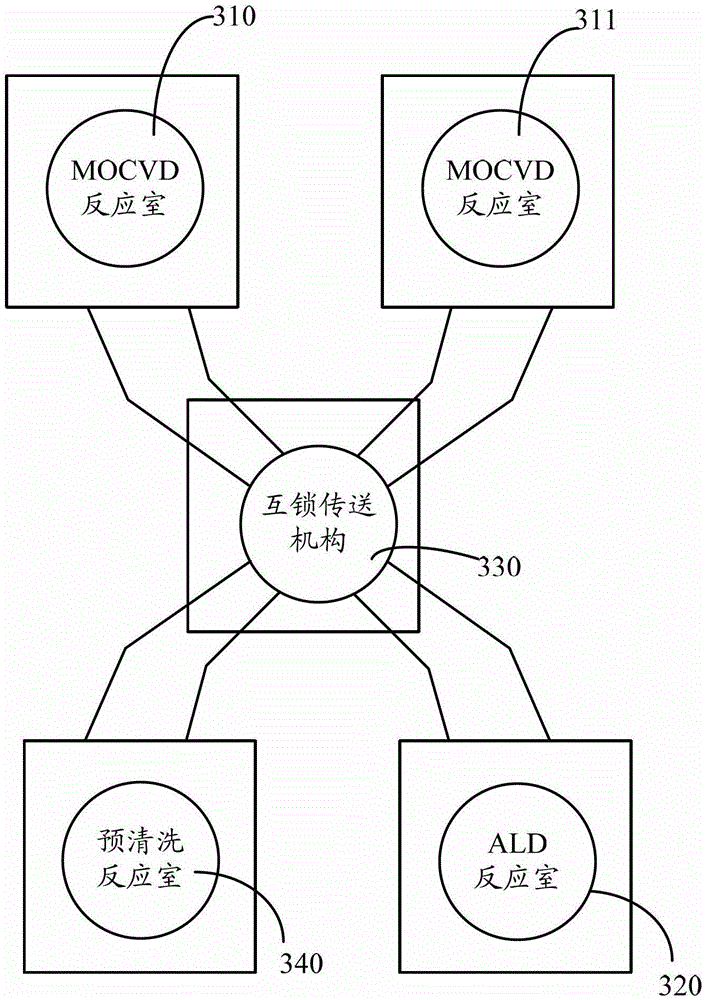

[0047] A system for preparing gallium nitride-based materials and devices of the present invention is an integrated system and includes:

[0048] One or more MOCVD reaction chambers;

[0049] One or more ALD reaction chambers;

[0050] And the interlocking transmission mechanism connected with the MOCVD reaction chamber and the ALD reaction chamber

[0051] Correspondingly, the preparation method of a gallium nitride-based material and device of the present invention includes:

[0052] Provide one or more MOCVD reaction chambers and one or more ALD reaction chambers;

[0053] Using the interlocking transfer mechanism, the gallium nitride-based materials to be grown are sequentially entered into different reaction chambers to grow corresponding epitaxial layers, or the devices to be processed are sequentially entered into different reaction chambers for corresponding processes. The reaction chamber works under the corresponding conditions, with corresponding gas or liquid or plasma input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com