A special-shaped high-bearing capacity concrete pile and its production method

A technology of concrete piles and production methods, which is applied to sheet pile walls, ceramic molding machines, manufacturing tools, etc., can solve the problems of small cross-sectional area, small vertical bearing capacity, and small mechanical properties, and achieve large effective cross-sectional area and external appearance. The effect of increased frictional resistance and high bearing capacity of single pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

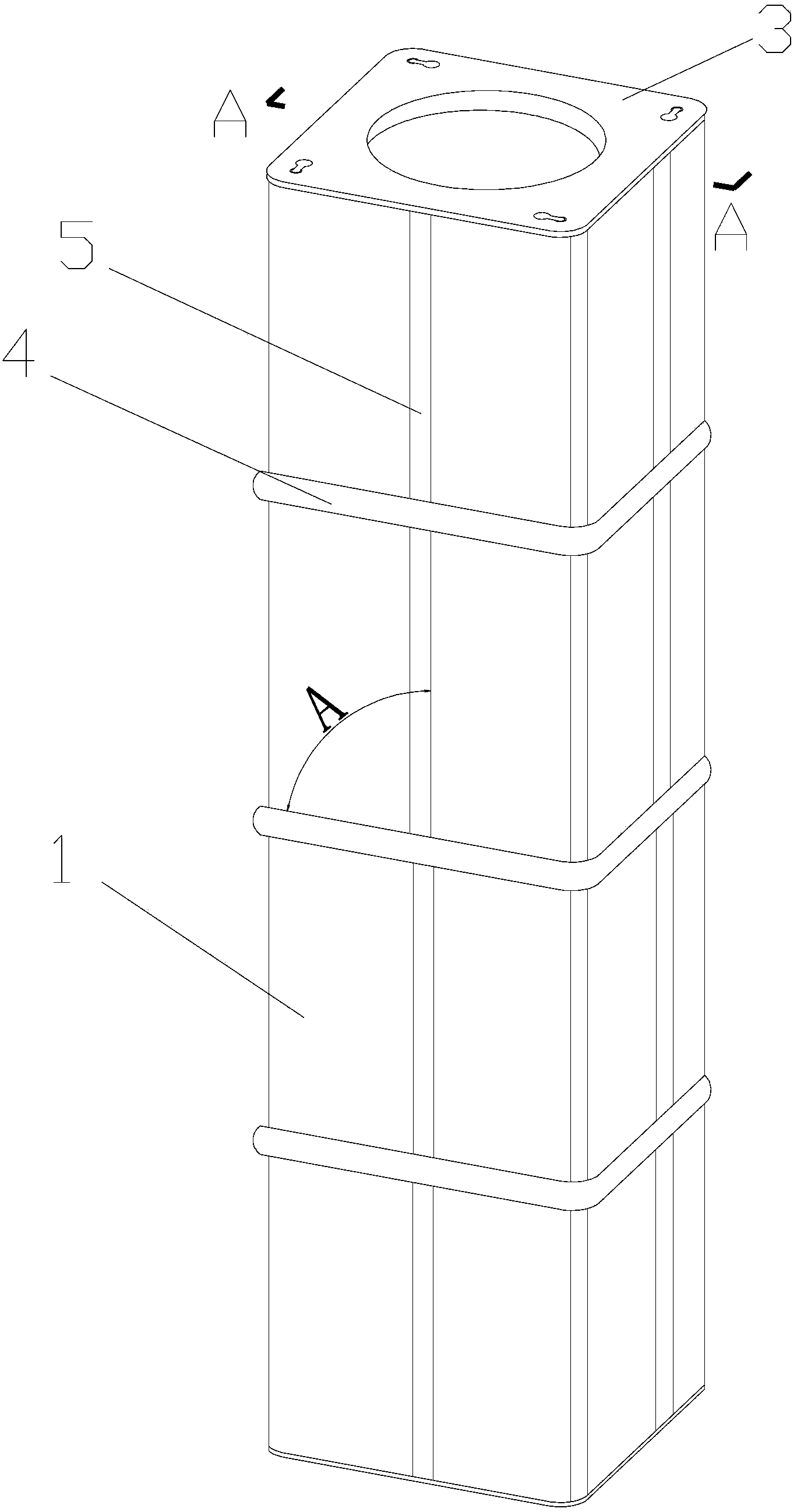

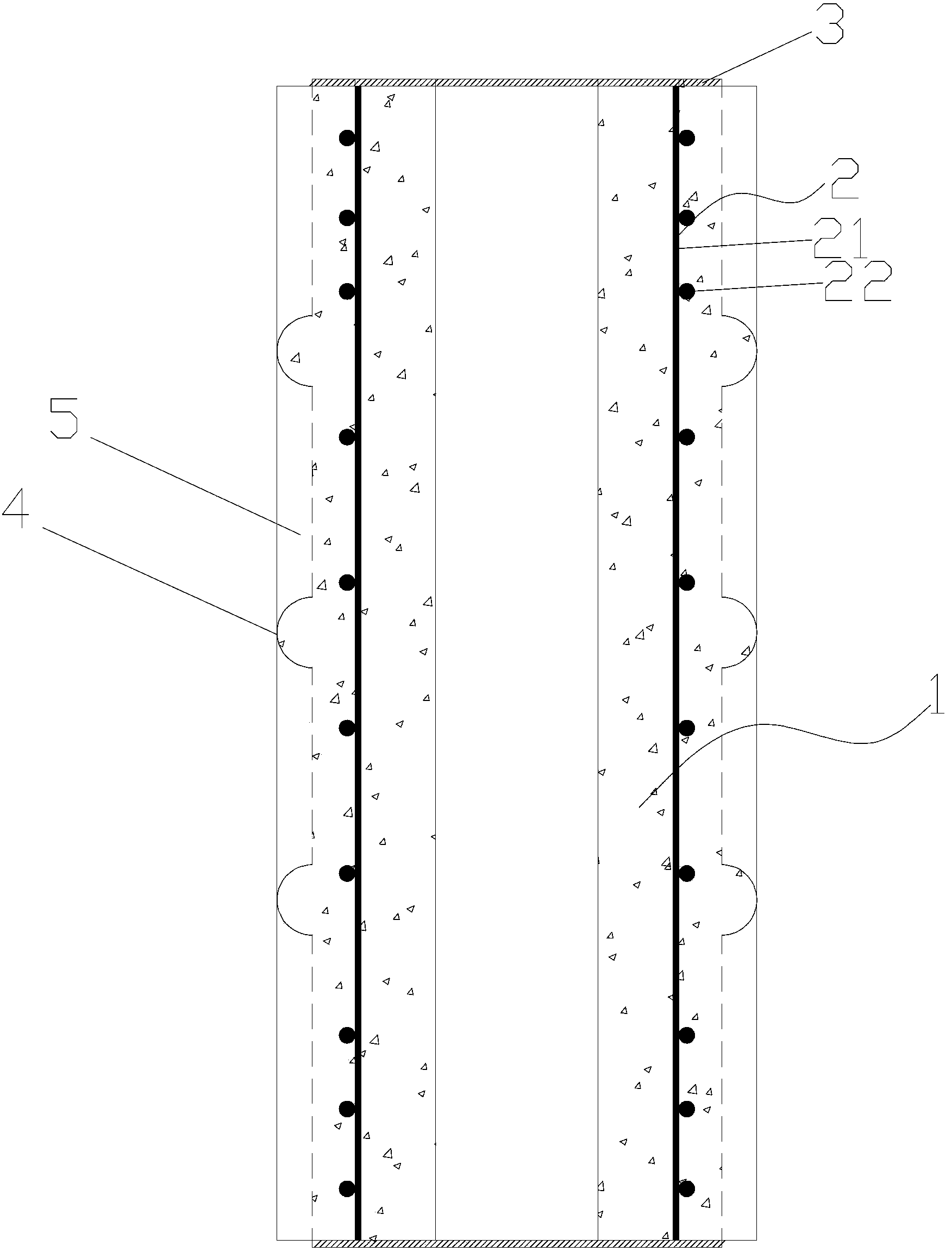

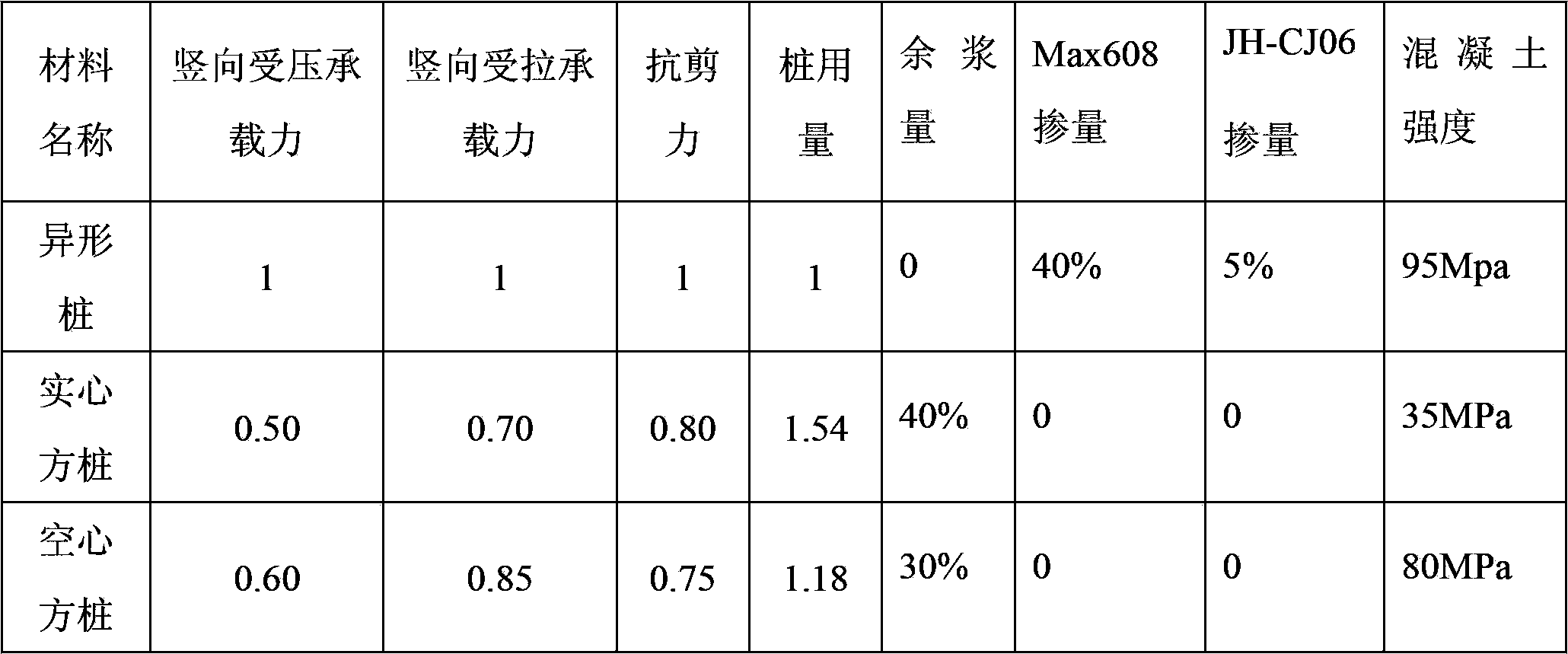

[0044]A special-shaped high-bearing-capacity concrete pile mainly includes a special-shaped pile body 1, a steel skeleton cage 2, an end plate 3, three surrounding ribs 4, and four special-shaped ribs 5. The special-shaped pile body 1 is centrifugally formed by concrete, and the section of the special-shaped pile body 1 is a hollow square. Concrete is mixed with 40% max608 accelerator and 5% JH-CJ06 grout removal agent. The reinforcement cage 2 mainly includes main reinforcement 21 and spiral stirrup 22 . The two ends of the special-shaped pile body 1 are respectively provided with hollow square or end plates 3 of the same shape as the cross-section of the special-shaped pile body 1. After the two ends of the steel skeleton cage 2 are connected with the end plates 3, they are centrifuged or vibrated together with the concrete. An integrally formed special-shaped high-bearing-capacity concrete pile with surrounding ribs 4, special-shaped ribs 5 and hollow. The cross-sectional...

Embodiment 2

[0060] A special-shaped high-bearing-capacity concrete pile mainly includes a special-shaped pile body 1, a steel skeleton cage 2, an end plate 3, three surrounding ribs 4, and four special-shaped ribs 5. The special-shaped pile body 1 is formed by concrete through vibration, and the section of the special-shaped pile body 1 is a hollow square. Concrete is mixed with 38% max608 accelerator and 5% JH-CJ06 grout removal agent. The reinforcement cage 2 mainly includes main reinforcement 21 and spiral stirrup 22 . The two ends of the special-shaped pile body 1 are respectively provided with hollow square or end plates 3 of the same shape as the cross-section of the special-shaped pile body 1. After the two ends of the steel skeleton cage 2 are connected with the end plates 3, they are centrifuged or vibrated together with the concrete. An integrally formed special-shaped high-bearing-capacity concrete pile with surrounding ribs 4, special-shaped ribs 5 and hollow. The cross-sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com